Testing and Commissioning in LV Panels Construction Works |LV Panels Package Factory Acceptance testing (FAT) | LV Panels Package Site Acceptance testing (SAT) | LV Panels Package Test Reports in Excel Sheet | LV Panels Package List of Tests | Low Voltage Panels Testing and Commissioning Requirement Compliance Sheet | Low Voltage Panels Systems List of Tests

In this article, we have listed out Types of FFS

(Fire Fighting System) Package Testing and Commissioning on factories and Sites

for construction works and Test Instrumentation Required/Considered for Site

Acceptance Testing (SAT)

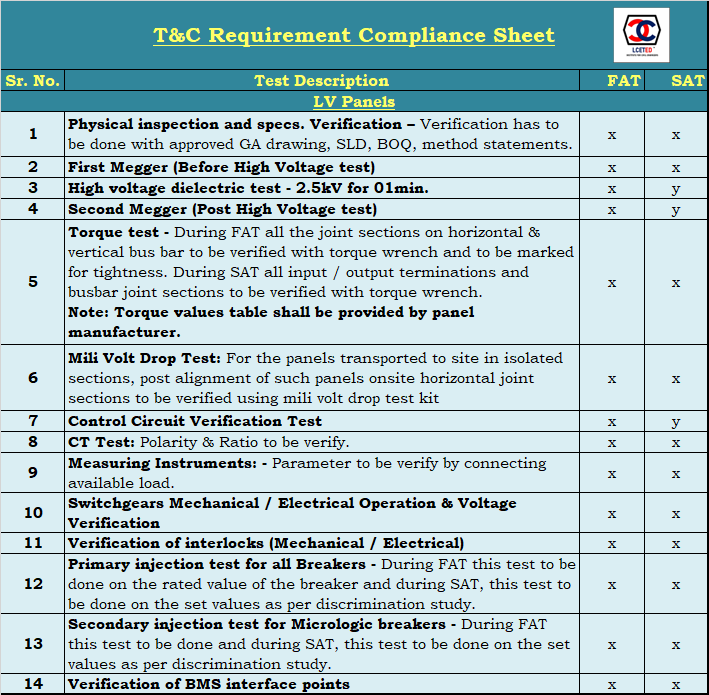

Following are the Low Voltage Panels Systems that shall be carried out in construction works

T&C

Requirement Compliance Sheet Required for LV Panels

1.

"Physical inspection and specs. Verification

– Verification has to be done with approved GA drawing, SLD, BOQ, and method

statements."

2.

First Megger (Before High Voltage test)

3.

High voltage dielectric test - 2.5kV for 01min.

4.

Second Megger (Post High Voltage test)

5.

Torque test - During FAT all the joint sections on the horizontal & vertical bus bars are to be verified with a torque wrench and to be

marked for tightness. During SAT all input/output terminations and busbar

joint sections are to be verified with a torque wrench. Note: The torque values table

shall be provided by the panel manufacturer.

6.

"Mili Volt Drop Test - For the panels transported to the site in isolated sections, post alignment of such panels onsite horizontal

joint sections to be verified using mili volt drop test kit"

7.

Control Circuit Verification Test

8.

CT Test: - Polarity & Ratio to be verify.

9.

Measuring Instruments: Parameter to be verified by

connecting available load.

10.

Switchgears Mechanical / Electrical Operation & Voltage Verification

11.

Verification of interlocks (Mechanical / Electrical)

12.

"Primary injection test for all Breakers - During FAT

this test is to be done on the rated value of the breaker and during SAT, this test is to be done on the set values as per discrimination study."

13.

Secondary injection test for Micrologic breakers

- During FAT this test is to be done and during SAT, this test is to be done on the

set values as per the discrimination study.

14.

Verification of BMS interface points

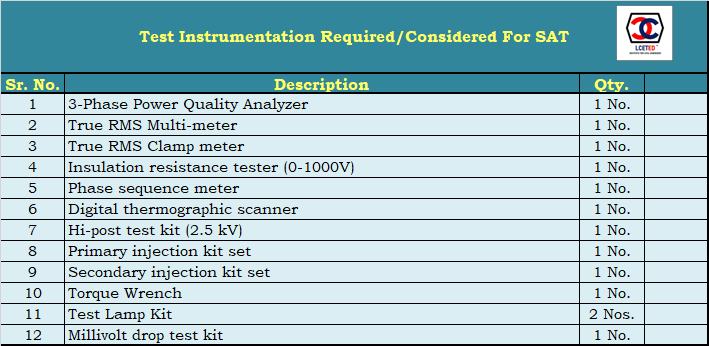

Test Instrumentation Required/Considered for LV Panels Site Acceptance Testing (SAT)

1. 3-Phase Power Quality Analyzer

2. True RMS Multi-meter

3. True RMS Clamp meter

4. Insulation resistance tester (0-1000V)

5. Phase sequence meter

6. Digital thermographic scanner

7. Hi-post test kit (2.5 kV)

8. Primary injection kit set

9. Secondary injection kit set

10. Torque Wrench

11. Test Lamp Kit

12. Millivolt drop test kit

NOTE: Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT)

CLICK TO DOWNLOAD EXCEL SHEET

No comments:

Post a Comment