Testing and Commissioning in HVAC Construction Works | HVAC Package Factory Acceptance testing (FAT) | HVAC Package Site Acceptance testing (SAT) | HVAC Package Test Reports in Excel Sheet | HVAC Package List of Tests | HVAC Package Testing and Commissioning Requirement Compliance Sheet | HVAC Systems List of Tests

In this article, we

have listed out Types of HVAC Package Testing and Commissioning on factories

and Sites for construction works and Test Instrumentation

Required/Considered for Site Acceptance Testing (SAT)

Following is the HVAC

Package that shall be carried out on construction works

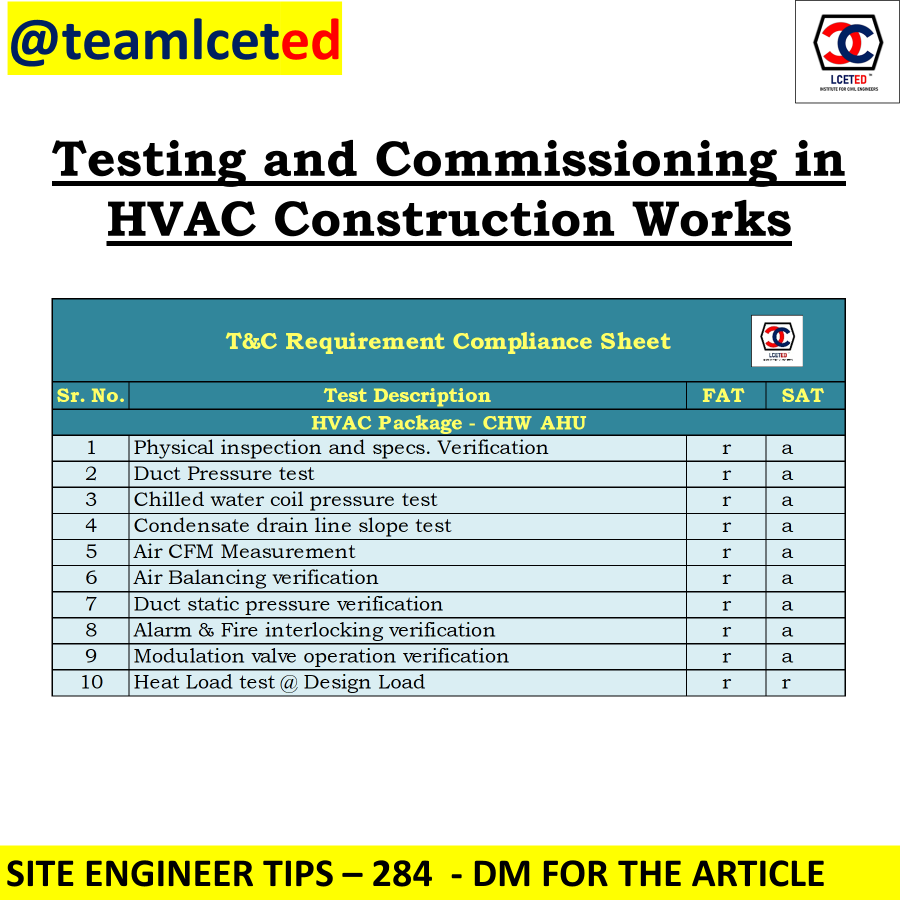

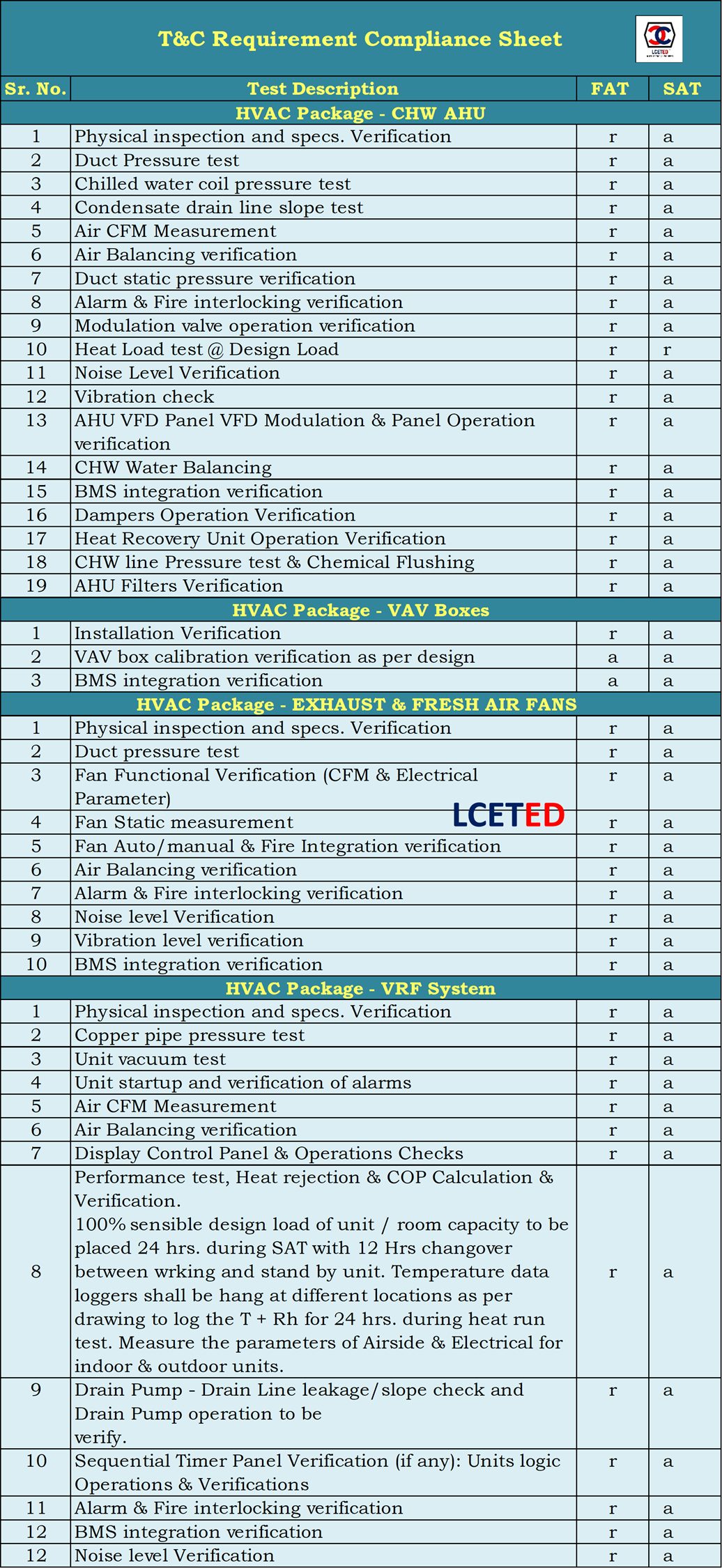

HVAC Package - CHW AHU

1. Physical

inspection and specs. Verification

2. Duct Pressure

test

3. Chilled water

coil pressure test

4. Condensate drain

line slope test

5. Air CFM

Measurement

6. Air Balancing

verification

7. Duct static

pressure verification

8. Alarm & Fire

interlocking verification

9. Modulation valve

operation verification

10. Heat Load test

@ Design Load

11. Noise Level

Verification

12. Vibration check

13. AHU VFD Panel

VFD Modulation & Panel Operation verification

14. CHW Water

Balancing

15. BMS integration

verification

16. Dampers

Operation Verification

17. Heat Recovery

Unit Operation Verification

18. CHW line

Pressure test & Chemical Flushing

19. AHU Filters

Verification

HVAC Package - VAV Boxes

1. Installation

Verification

2. VAV box

calibration verification as per design

3. BMS integration

verification

HVAC Package - EXHAUST & FRESH AIR FANS

1. Physical

inspection and specs. Verification

2. Duct pressure

test

3. Fan Functional

Verification (CFM & Electrical Parameter)

4. Fan Static

measurement

5. Fan Auto/manual

& Fire Integration verification

6. Air Balancing

verification

7. Alarm & Fire

interlocking verification

8. Noise level

Verification

9. Vibration level

verification

10. BMS integration

verification

HVAC Package - VRF System

1. Physical

inspection and specs. Verification

2. Copper pipe

pressure test

3. Unit vacuum test

4. Unit startup and

verification of alarms

5. Air CFM

Measurement

6. Air Balancing

verification

7. Display Control

Panel & Operations Checks

8. "Performance

test, Heat rejection & COP Calculation & Verification.

100% sensible

design load of unit/room capacity to be placed 24 hrs. during SAT with 12 Hrs.

changeover between working and standby unit. Temperature data loggers shall hang

at different locations as per drawing to log the T + Rh for 24 hrs. during the heat

run test. Measure the parameters of Airside & Electrical for indoor &

outdoor units."

9. "Drain Pump

- Drain Line leakage/slope check and Drain Pump operation to be

verify."

10. Sequential

Timer Panel Verification (if any): Units logic Operations & Verifications

11. Alarm &

Fire interlocking verification

12. BMS integration

verification

13. Noise level

Verification

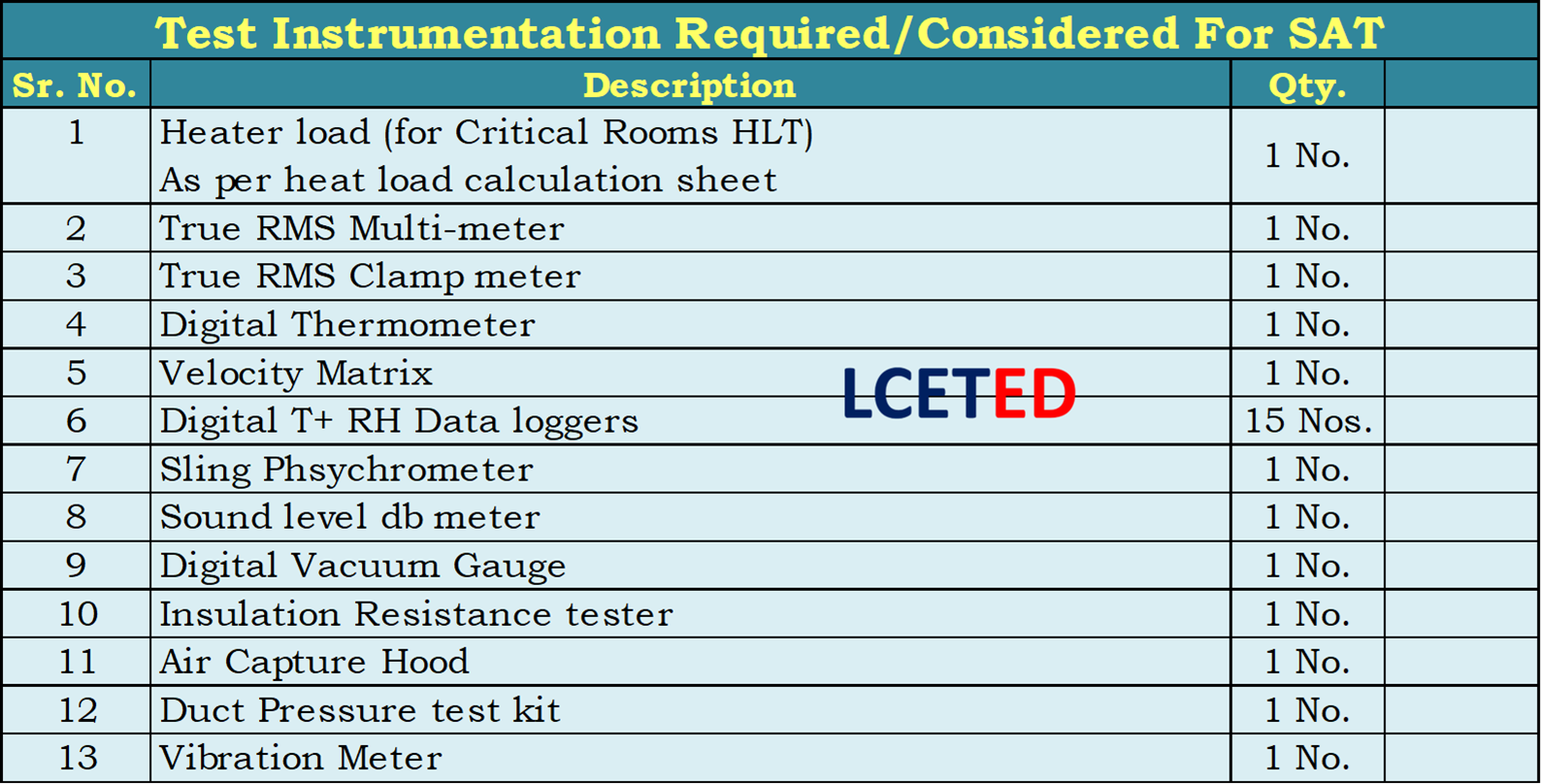

Test Instrumentation Required/Considered For SAT

Following is the

Test Instrumentation Required/Considered for Site Acceptance Testing (SAT) of the HVAC

Package

1. "Heater

load (for Critical Rooms HLT)

As per the heat load

calculation sheet"

2. True RMS Multi-meters

3. True RMS Clamp

meter

4. Digital

Thermometer

5. Velocity Matrix

6. Digital T+ RH

Data loggers

7. Sling Psychrometer

8. Sound level db.

meter

9. Digital Vacuum

Gauge

10. Insulation

Resistance tester

11. Air Capture

Hood

12. Duct Pressure

test kit

13. Vibration Meter

CLICK TO DOWNLOAD

EXCEL SHEET

No comments:

Post a Comment