Quality Inspection Checklist for Plumbing Works | Plumbing Inspection Checklist | Work Checklist - Internal Plumbing Work | Checklist for Plumbing | Plumbing Checklist

In this article, we have discussed and enclosed the quality Inspection checklist for Plumbing works in construction to be used by civil engineers

Quality

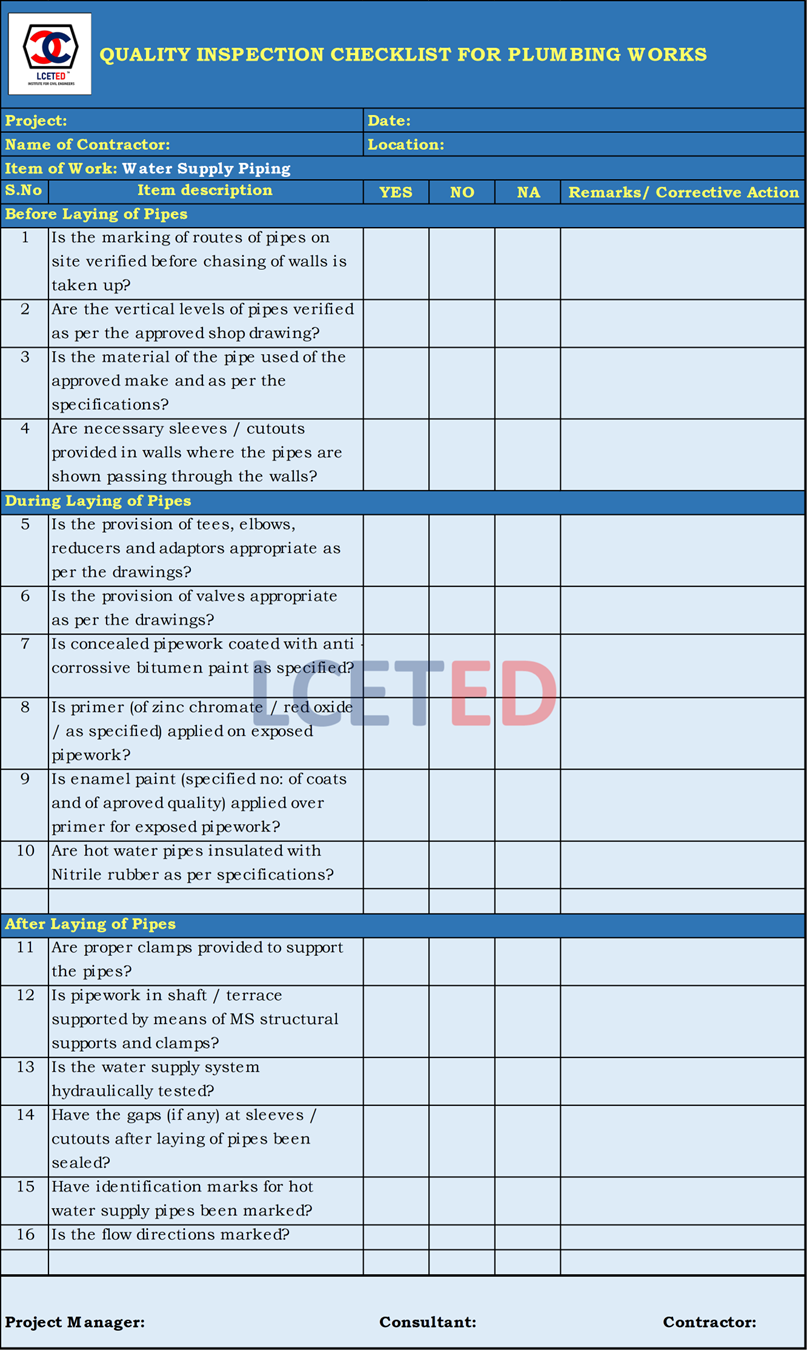

Inspection Checklist of Water Supply Piping | Quality

Inspection Checklist of Internal Water Supply Piping

Before Laying of Pipes

1.

Is the marking of routes of pipes on-site verified before the chasing of walls is

taken up?

2.

Are the vertical levels of pipes verified as per the approved shop drawing?

3.

Is the material of the pipe used of the approved make and as per the

specifications?

4.

Are necessary sleeves/cutouts provided in walls where the pipes are shown

passing through the walls?

During the Laying of Pipes

5.

Is the provision of tees, elbows, reducers, and adaptors appropriate as per the

drawings?

6.

Is the provision of valves appropriate as per the drawings?

7.

Is concealed pipework coated with anti-corrosive bitumen paint as specified?

8.

Is primer (of zinc chromate / red oxide / as specified) applied on exposed

pipework?

9.

Is enamel paint (specified no: of coats and of approved quality) applied over

primer for exposed pipework?

10.

Are hot water pipes insulated with Nitrile rubber as per specifications?

After Laying of Pipes

11. Are proper clamps provided to support the pipes?

12. Is pipework in the shaft/terrace supported by

means of MS structural supports and clamps?

13. Is the water supply system hydraulically tested?

14. Have the gaps (if any) at sleeves/cutouts

after laying of pipes been sealed?

15. Have identification marks for hot water supply

pipes been marked?

16. Is the flow directions marked?

Quality

Inspection Checklist of Soil, Waste, and Vent Piping

Before Laying of Pipes

1. Is the marking of routes of pipes on-site

verified before the chasing of walls is taken up?

2. Are the vertical levels of pipes verified as per

the approved shop drawing?

3. Is the material of the pipe used of the approved

make and as per the specifications?

4. Are necessary sleeves/cutouts provided in walls

where the pipes are shown passing through the walls?

During the Laying of Pipes

5. Are pipes laid in sunken floors encased in

concreting adequately as specified?

6. Are pipes underslung from the ceiling have proper MS

structural supports and clamps?

7. Is the spacing between the supports and clamps

proper?

8. Is the provision of tees, elbows, reducers, and

adaptors appropriate as per the drawings?

9. Is the provision of valves appropriate as per the

drawings?

10. Is primer being applied on exposed pipes?

11. Is the specified number of coats of enamel paint

applied over primer on exposed pipes as per the specifications?

12. Is the concealed pipework coated with anti-corrosive paint as per the specifications?

After Laying of Pipes

13. Is the drainage system hydraulically tested?

14. Have the gaps (if any) at sleeves/cutouts

after laying of pipes filled with cement concrete and sealed with an approved

sealant?

15. Is the flow directions marked?

Quality

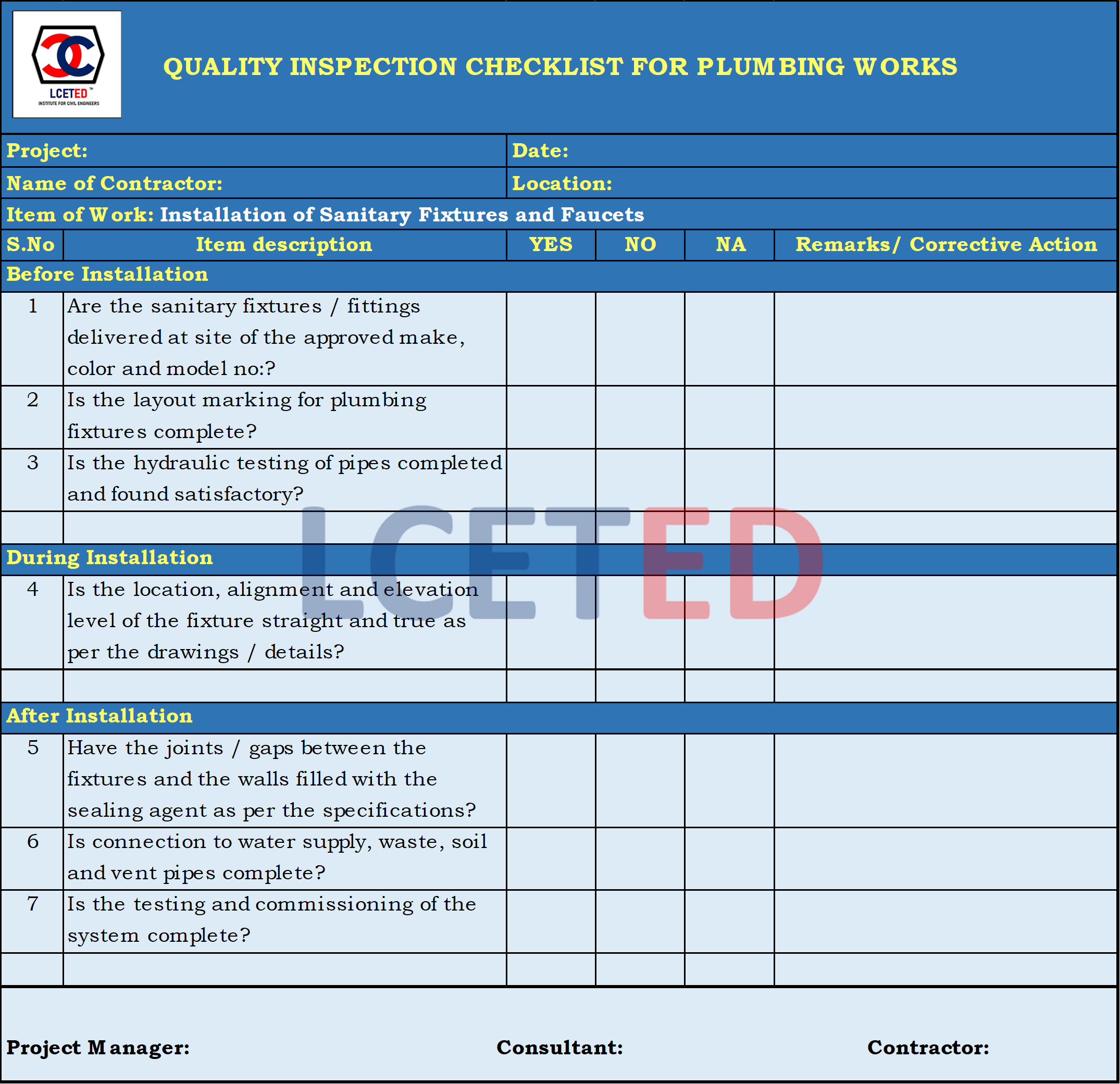

Inspection Checklist on Installation of Sanitary Fixtures and Faucets

Before Installation

1. Are the sanitary fixtures/fittings delivered at the site of the approved make, color, and model no:

2. Is the layout marking for plumbing fixtures complete?

3. Is the hydraulic testing of pipes completed and

found satisfactory?

During Installation

5. Is the location, alignment, and elevation level

of the fixture straight and true as per the drawings/details?

After Installation

6. Have the joints/gaps between the fixtures and the walls filled with the sealing agent as per the specifications?

7. Is the connection to the water supply, waste, soil, and

vent pipes complete?

8. Is the testing and commissioning of the system complete?

No comments:

Post a Comment