Quality Inspection Checklist for Firefighting Works | Building Inspection Checklist for Fire and General Safety | Inspection Checklist Fire Protection Equipment

In this article, we have discussed and enclosed the quality Inspection checklist for firefighting Works (FFS) in construction to be used by civil engineers

Quality

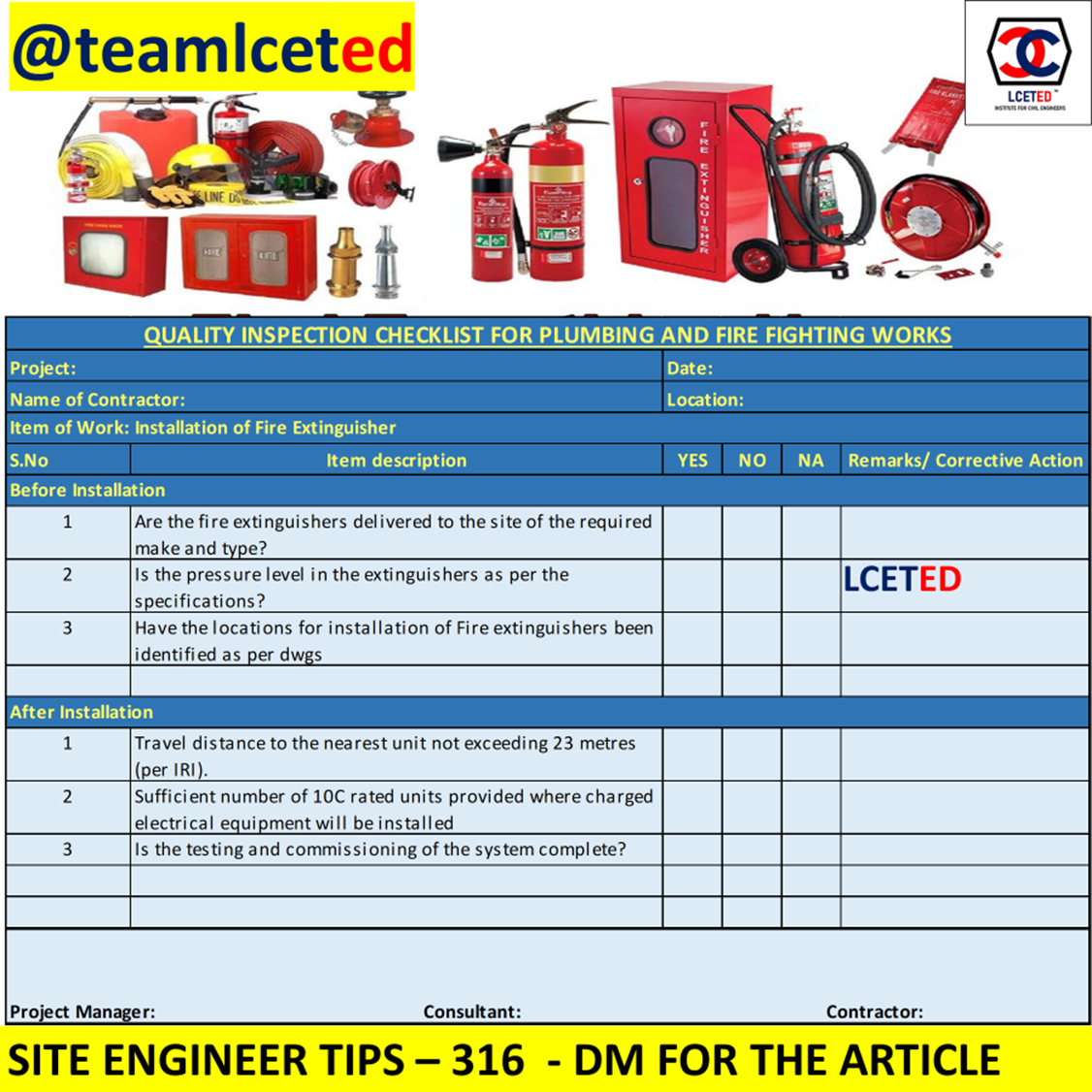

Inspection Checklist on Installation of Fire Extinguisher

Before Installation

1. Are the fire extinguishers delivered to the site

of the required make and type?

2. Is the pressure level in the extinguishers as per

the specifications?

3. Have the locations for installation of Fire

extinguishers been identified as per drawings

After Installation

1. Travel distance to the nearest unit not exceeding

23 meters (per IRI).

2. Enough 10C rated units provided where charged

electrical equipment will be installed

3. Is the testing and commissioning of the system complete?

Quality

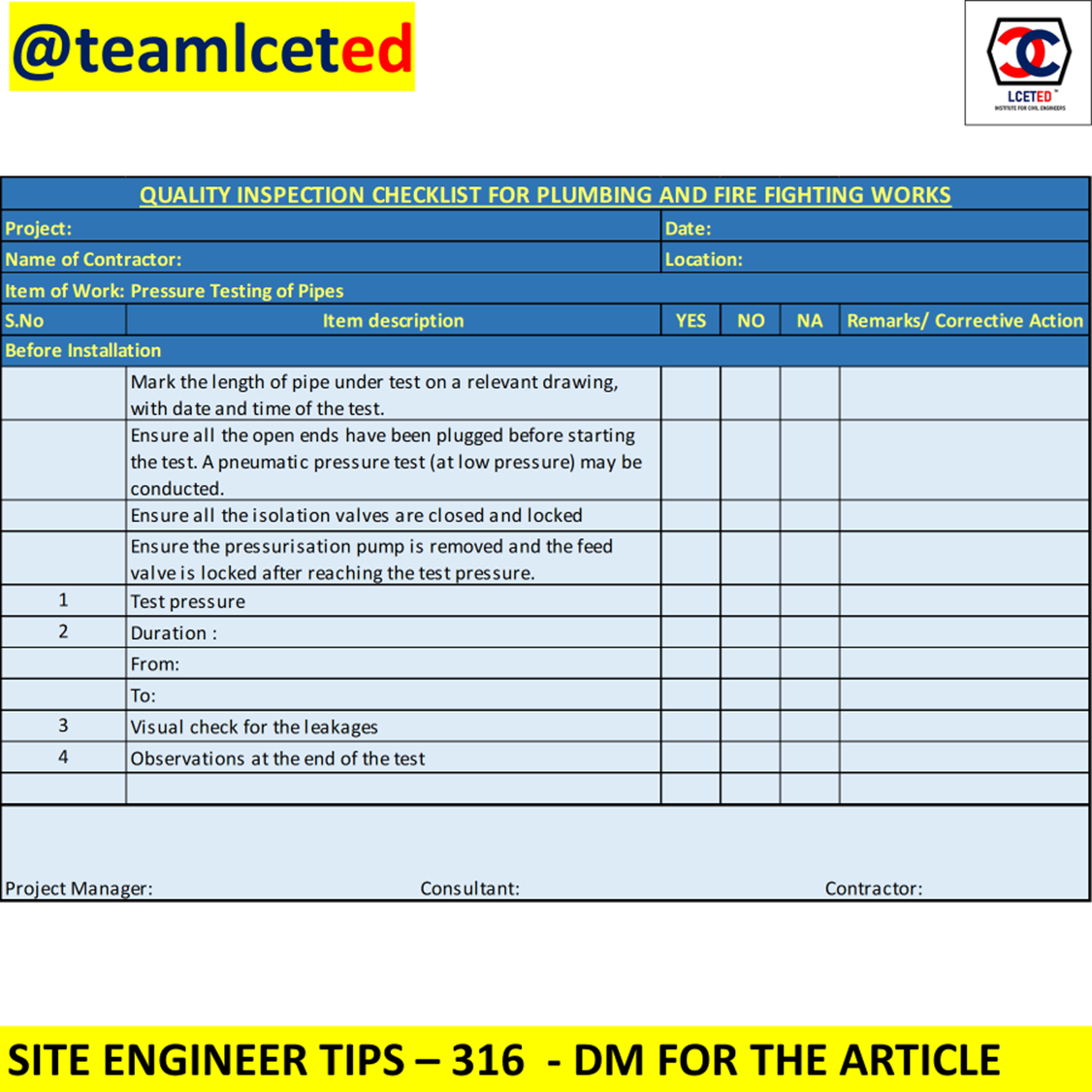

Inspection Checklist on Pressure Testing of Pipes

Before Installation

1. Mark the length of the pipe under test on a relevant

drawing, with the date and time of the test.

2. Ensure all the open ends have been plugged in before

starting the test. A pneumatic pressure test (at low pressure) may be

conducted.

3. Ensure all the isolation valves are closed and

locked

4. Ensure the pressurization pump is removed and the

feed valve is locked after reaching the test pressure.

a. Test pressure

b. Duration:

From:

To:

c. Visual check for the leakages

d. Observations at the end of the test

Quality

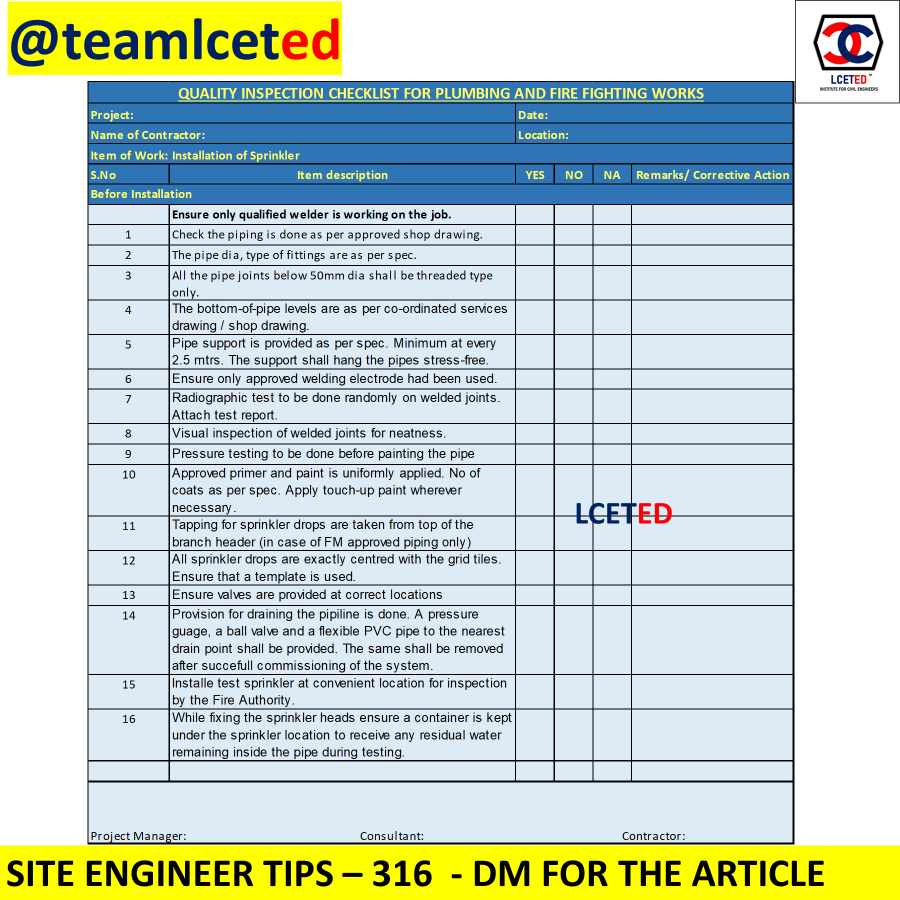

Inspection Checklist on Installation of Sprinkler

Before Installation - Ensure only a qualified welder is working on the job.

1. Check the piping is done as per the approved shop

drawing.

2. The pipe diameter, type of fittings is as per

spec.

3. All the pipe joints below 50mm diameter shall be

threaded type only.

4. The bottom-of-pipe levels are as per the coordinated

services drawing / shop drawing.

5. Pipe support is provided as per spec. Minimum at

every 2.5 meters. The support shall hang the pipes stress-free.

6. Ensure only approved welding electrodes had been

used.

7. Radiographic test to be done randomly on welded

joints. Attach test report.

8. Visual inspection of welded joints for neatness.

9. Pressure testing is to be done before painting the

pipe

10. Approved primer and paint are uniformly applied.

No coats as per spec. Apply touch-up paint wherever necessary.

11. Tapping for sprinkler drops is taken from the top

of the branch header (in case of FM-approved piping only)

12. All sprinkler drops are exactly centered with

the grid tiles. Ensure that a template is used.

13. Ensure valves are provided at the correct locations

14. Provision for draining the pipeline is done. A

pressure gauge, a ball valve, and a flexible PVC pipe to the nearest drain point

shall be provided. The same shall be removed after the successful commissioning of

the system.

15. Installed test sprinkler at a convenient location

for inspection by the Fire Authority.

16. While fixing the sprinkler heads ensure a container is kept under the sprinkler location to receive any residual water remaining inside the pipe during testing.

No comments:

Post a Comment