In this article, we have explained material tracker uses and how to prepare it for your project

A construction project cannot progress without

construction materials. Whether you're working on interior fit-out or base

build. Need Detailed planning is involved in managing thousands of line

items across the supply chain and material tracking systems are used to control

the supply and delivery of each part making a successful project.

What are the advantages of Material tracking

systems?

1. Material loss prevention.

2. Approved make & specification of materials

3. Reduce time spent searching for materials (eg at

laydown yards)

4. Preparation of Storage system for Material before its

arrival

5. Record the chain of custody from fabrication to

installation.

6. Expect/Forecast delays and disruptions.

7. Improve accountability among all stakeholders.

8. Use reliable real-time field data for reporting and

decision-making.

9. Generate insights about usage and utilization.

10. Digitize the tracker to send mail to stakeholders

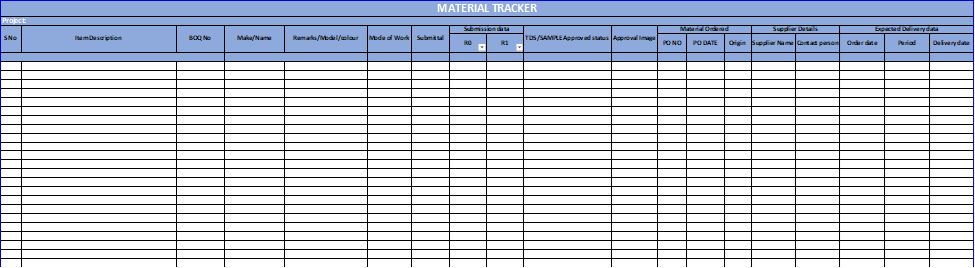

The following data need to be listed sheet

1. S. No

2. Item Description

3. BOQ No

4. Make/Name

5. Remarks/Model/Color

6. Mode of Work

7. Submittal

8. Submission data – R0-R1

9. TDS /SAMPLE Approved status

10. Approval Image

11. Material Ordered – 1. PO Number 2. PO Date 3. Origin

12. Supplier Details – 1. Supplier Name 2. Contact Person

13. Expected Delivery data – 1. Order Date 2. Period 3.

Delivery Date

MATERIAL

TRACKER SHEET FORMAT

Maintain

a record every week (Certain period) of material changes status, location, or

custodian. This creates accountability for stakeholders. By making a habit of tracking

and checking material in and out to move them through the process, you’ll be

able to forecast the delay of material.

No comments:

Post a Comment