This method of strengthening columns and beams is easy, as the method follows normal construction. In beams, we may have to strengthen them to reduce deflection also. Jacketing is the provision of a concrete jacket with extra steel if needed. The jacket goes all around the member. The rehabilitation of beams and columns by RC jacketing (the concrete being placed by labor and not by mechanical means) is briefly described in this chapter. We deal with the following in this article:

1. RC jacketing of a column

2. RC jacketing of beams

RC Jacketing of a Column

The following is a brief

step-by-step procedure for strengthening a column by jacketing it with reinforced

concrete. In this article, we deal with the strengthening of the main column.

Step 1:

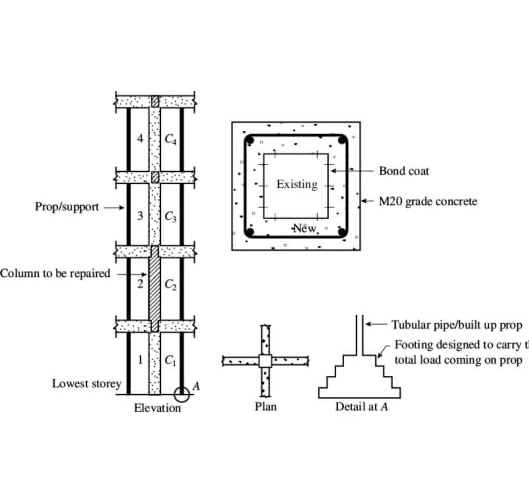

1. Prop up and support the beam near the beam–column

joints to relieve the column of some of the load, as shown in Figure below the

props should be telescopic tubular steel props. In a multistoried building,

props should be provided for all the column joints above and below the column

being taken for strengthening. The order of fixing support should be from the

bottom to top. (The order of removing support after repair should be from top

to bottom.)

2. Remove the external plaster of the column to be

repaired.

3. Remove the unsound concrete cover and the portion

around the steel.

Figure: RC jacketing of columns.

4. Clean the concrete and steel surfaces and paint the

steel with a corrosion inhibitor, if needed.

5. We install shear key reinforcements to make the new

concrete act with the old concrete. For installing shear keys, drill holes to

sufficient depths along the height of the column. Clean the holes, inject epoxy

from foil packs and insert the reinforcement bars. Allow the epoxy to cure (this is

done in addition to the bonding coat).

6. Put additional column reinforcement with required

laterals and tie up the steel.

Step 2:

Apply a bond coat to concrete and steel to make new and old acts together.

Step 3:

Fabricate and erect watertight shuttering.

Step 4:

Pour the self-compacting or free-flowing concrete so that we do need not to use a

vibrator and compact the concrete well. This should be carried out before the

bond coat dries up. (Otherwise, pour conventional concrete and use a proper

vibrator to place the concrete.)

Step 5:

Cure the concrete, add finishing plaster, etc., as needed.

Note: This jacketing can also be done with ferrocement

using weld mesh and chicken mesh and cement mortar without

RC Jacketing of Beams

First, we design the size

and required steel so that the strength and deflection satisfy our

requirements. As it is difficult to put formwork etc. to a beam because of many

reasons, we proceed as follows:

Step 1: Support the beam at the midpoint (or other points in the

slab also) to reduce the load acting on the beam.

Step 2: Chip off the plaster and damaged concrete, if present.

Step 3: Add extra steel reinforcement, if needed, and support

the steel ends by drilling holes in the column and grouting the hole with epoxy

grout, and inserting the steel. Also, tie or weld additional steel to the steel

present in the beam.

Step 4: Fix an expanded wire mesh around the beam on three

sides, as shown in the Figure below, leaving the necessary gap for additional concrete

between the old beam and the wire mesh.

The figure below, the RC jacketing of beams (a) repair scheme of

the beam (b) expanded wire mesh placed in position, and (c) polymer-modified

mortar being applied.

Step 5: Apply an epoxy bond coat to the old concrete surface.

Step 6: While the bond coat is still fresh, apply polymer-modified mortar (by a mason or by hand, or by means of travel) to get the

required thickness on all three sides of the beam. This can be obtained by

2 or 3 applications of mortar.

Step 7: The beam is water cured for at least 3 days and then,

air-cured. Release all the props under the beams. Through this process, we get a

stronger beam.

Summary

RC jacketing is jacketing with an additional layer of steel

and concrete. It is one of the simple methods of strengthening columns and

beams

.jpeg)

No comments:

Post a Comment