In this article, we explained how to prepare a bill of quantity for false ceilings - Seamless Gypsum board False ceiling, Cove lighting, Grid ceiling, Recess in Gypsum board False ceiling as per Architect Drawing, Aluminum baffle ceiling, Metal works baffle Ceiling, Laminated Ceiling, Honeycomb Timber False Ceiling, Perforated Gypsum board false ceiling/wall and Trap door

General notes to be mentioned in false ceiling BOQ

Providing and fixing Suspended False Ceiling which includes Gypsum Plaster board 12.5mm thick., False Ceiling on 24-gauge G.I. framework which includes Providing. & Fixing G.I. perimeter channels 0.55 mm thick 20mmx30mm, web size 27mm along perimeter of ceiling, screw fixed to brick wall/partition with nylon sleeves & screws @ approx. 2'0" c/c. Suspending G.I. intermediate channels size 45 mm,0.9 mm thick, flanges of size15mm each from the soffit 1220mm c/c with ceiling angle 25 x10mm x 0.55mm thick fixed to soffit G.I. cleat & steel expansion fasteners.

Ceiling section of 0.55mm thick having web of 51.5mm

& flanges 26 mm each lips 10.5 mm

fixed to intermediate channel with

connecting clips & perpendicular to int channel @ 457mm c/c.12.5 mm tapered edge Plaster board ( IS

2095-1982 ) screw fixed to ceiling section with 25mm dry wall screws @ 230 mm

c/c. Boards to be joint & finished so as to have flush look including

filling finishing edges with jointing

compound paper tape/cloth gauze & 2 coats of primer suitable for plaster

board. Rate to include M.S. framing around A/C ducts wherever necessary.

"Rate to include cove to profile, cut-outs for

light fixtures, spotlights, smoke detectors, Vertical risers up to 200mmht as

shown in dwg. and all services cut outs as required. complete as directed by

Project manager / Architect.

Note:

for Light fittings, Grills, diffusers, and other cut-outs must be made with a

frame of perimeter channels of size 20mm x 27mm x 30mmx 0.55mm thick, supported

suitably. Quoted rate shall also to include the Engineered system made up of

primary sections in galvanized steel of 21x35x3600mm in 0.75 bmt gauge. with

top cross rails and the system shall be used at 1200mm apart where direct

suspenders cannot be used due to overhead ducting or any other services.

Mode of measurement:

Finished plan ceiling area shall be measured for payment.

How to prepare BOQ for Seamless Gypsum board False ceiling?

Bill of quantity (BOQ) of Seamless Gypsum board False

ceiling

Providing and fixing in position multi-level GYPSUM

board false ceiling suspended on G.I. framework in design as shown in the

drawing. The G.I. framework consist of

Perimeter channel of size 27mm x 0.5mm.

Intermediate channel of size 45mm x 0.5mm thick. Ceiling section of 0.5mm thickness.

12.5mm thick tapered edge gypsum plaster board fixed to

ceiling channel with 25mm dry wall screws at 230mm centers Jointed and finished

with requisite filler, paper tape, finisher, and primer suitable for Gypsum

plaster boards & finishing the same with 3coats of acrylic emulsion paint

as/app. Rate to include making necessary

cut-outs/openings for light fittings, diffusers etc. All components to be of India Gypsum& all

spacings should match their recommendation & standards.

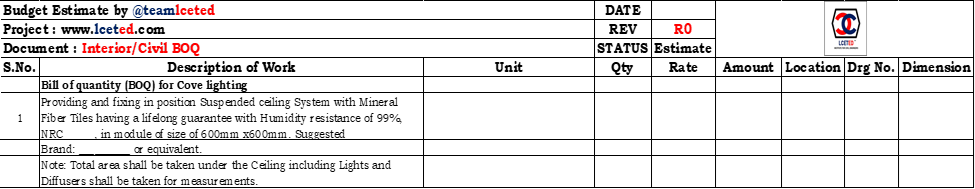

How to prepare BOQ for Cove lighting?

Bill of quantity (BOQ) for Cove lighting

Providing and fixing 50/75/100mm height Gypsum

vertical for cove lighting with G.I Channel framework and supports. Rate

inclusive of Painting

All round False ceiling 300 mm either side

How to prepare BOQ for Grid ceiling?

Bill of quantity (BOQ) for Grid ceiling

Providing and fixing in position Suspended ceiling System

with Mineral Fiber Tiles having a lifelong guarantee with Humidity resistance

of 99%, NRC______, in module of size of 600mm x600mm. Suggested

Brand: __________

or equivalent.

Note:

Total area shall be taken under the Ceiling including Lights and Diffusers

shall be taken for measurements.

How to prepare BOQ for Recess in Gypsum board False ceiling as per Architect Drawing?

Bill of quantity (BOQ) for Recess in Gypsum board False ceiling

as per Architect Drawing

How to prepare BOQ for Aluminum baffle ceiling?

Bill of quantity (BOQ) for Aluminum baffle ceiling

Option 1: Aluminum baffle ceiling with timber finish

Providing and fixing Aluminum Baffle ceiling system with

timber finish, Baffle width of 25mm x 50mm height X 0.5 mm thick and gap

between baffles to be 50mm c/c. The baffles shall be fixed to Carrier. The

Carriers shall be suspended by means of 6mm threaded rod at 1200 mm c/c. Rate

to include for acoustical Fleece of porous material of 2-3mmthk over 2mmthk MDF

fixed to the aluminum baffle as per the Manufactures recommendation etc.

complete as per the details shown in the drawing. Color to match pine wood

finish. Contractor to furnish the sample for Architect's approval. Basic price

-Rs. _______/smt +_____/sqm for Acoustical Fleece

Option 2: Aluminum baffle ceiling

Aluminum baffles shall be finished with powder coating of

2.5 microns to match pine wood finish Interior Grade As per Architects

Instruction and False ceiling drawing no._______

Consider Basic cost of Baffle ceiling at Rs. _____/sqm

Excluding taxes+_____/sqm for Acoustical Fleece

Mode of measurement: ceiling plan area shall be measured

for payment.

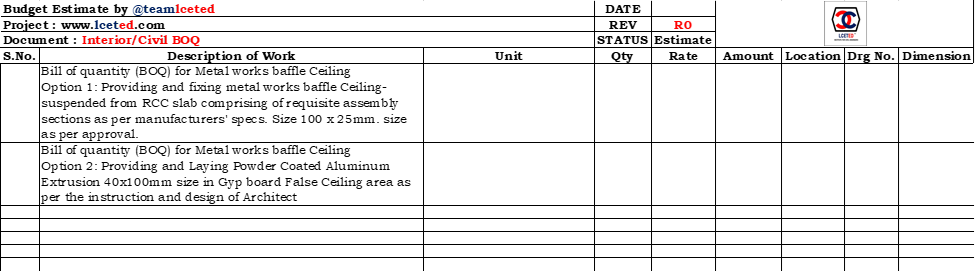

How to prepare BOQ for Metal works baffle Ceiling?

Bill of quantity (BOQ) for Metal works baffle Ceiling

Option 1: Providing and fixing metal works baffle

Ceiling- suspended from RCC slab comprising of requisite assembly sections as

per manufacturers' specs. Size 100 x 25mm. size as per approval.

Option 2: Providing and Laying Powder Coated Aluminum Extrusion

40x100mm size in Gyp board False Ceiling area as per the instruction and design

of Architect

How to prepare BOQ for Laminated Ceiling?

Bill of quantity (BOQ) for Laminated Ceiling

Providing and fixing Laminated Ceiling pricing of

necessary framework of well-seasoned Hard wood suspended from true ceiling and

fixed with 12mm thick common ply as base and finished with 1mm laminate as per

approval. The same shall be turned 75mm on sides. Provision for cove/surface

lights will have to be kept.

How to prepare BOQ for Honeycomb Timber False Ceiling?

Bill of quantity (BOQ) for Honeycomb Timber False

Ceiling

Honeycomb-Hexagon false ceiling panel size of 900 x 900

mm - finished with approved 1mm Thick approved laminate on 4mmthk MDF Hot Pressed,

with vertical support system from true ceiling formed out of Hilti Plugs,

aircraft suspension cables and bottom end cable adjusters etc. complete as per

the detailed dwg or the instructions of the Architects.

Mode of measurement:

Running Length of The Trouff shall be measured for payment.

Note:

Factory Finished with Clip on System will be preferred.

How to prepare BOQ for Perforated Gypsum board false ceiling/wall?

Bill of quantity (BOQ) for Perforated Gypsum board false ceiling/wall

Providing and Laying Perforated Seamless Gypsum Board False

Ceiling around Timber slit false ceiling with Acoustic panel in facia of false

ceiling

Providing and fixing suspended Perforated Gypsum false

ceiling of approved dimension with round random perforation G8/15/20 with 9.9%

perforation, NRC up to 0.55: Round rectangular perforation of glass-fiber

reinforced gypsum material, which includes providing and fixing GI perimeter

channels of size 0.55 mm. Thick. having one flange of 20 mm and another flange

of 30 mm and web of 27 mm along the perimeter of the ceiling, screw fixed to

brick wall/ partition with help of nylon sleeves and screws, at 610 mm centers.

The suspended GI intermediate channels of size 45

mm,0.9mm thick with two flanges of 15 mm each from the soffit at 900 mm centers

with ceiling angle of width 25mm x 10mm x 0.55mm thick fixed to soffit with GI

cleat and steel expansion fasteners. Ceiling section of 0.55 mm thick having

web of 51.5mm & two flanges of 26mm each with lips of 10.5mm are fixed to

the intermediate channels with help of connecting clips and in direction

perpendicular to the intermediate channel with centers of 333 mm perforated gypsum

board is then screw fixed to ceiling section with 25 mm dry wall screws at 300 mm

centers to G.I. framing in perfect level. Screw fixing is done mechanically either

with screwdriver or drilling machine with suitable attachment. Finally, the

boards are to be joined and finished to have a flush look with uniflot.

Example report: Cleaneo Technology- Air

purification & Air quality. Active reduction of air pollutants thanks to Cleaned

Technology effectively reduces concentrations of VOC’s like alcohol, aldehydes,

ketons and esters as well as unpleasant odors from e.g. food or cigarette smoke

Air purification properties

tested according to CEN standards and VDI guidelines by Fraunhof Institute for

Building Physics

The false ceiling surfaces

shall be prepared to the satisfaction of the Architect, and shall be applied

with two coats of primer and Paint to the satisfaction of Architects.

Perforated Gypsum board false ceiling/wall

Bill of quantity (BOQ) for Trap

door

Option 1: Providing and Fixing of Readymade “AMF"

19mm Marine Plywood Trap door finishing with metal GI frames with metal hinges

and safely secured with safety chain with lockable system and Allen key (door

opening size 1.8mx1.2m)

Option 2: P/F Trap Door in Gypboard ceiling, size upto

600x600 as per service requirement.

Option 3: P/F Trap Door in Gypboard ceiling, size upto

1800x2100 as per service requirement.

dd

No comments:

Post a Comment