Plaster is a mixture of building materials such as cement, sand and waterproofing admixtures (if need) which is used to coat walls and ceilings. Cement and sand are mixed with water using a mix ratio to form a plaster material

Also read: What is the cost of plastering the walls? Plastering Material & Labour Cost

Types

of Plastering:

· Interior

Plastering

· Exterior

Plastering

· Ceiling

Plastering

· Water-proofing

Plastering

The following points have to

be considered while Plastering work Rate analysis

1. Manpower

wages + including their transportation

2. Labour

Output per day

3. Material

Required + wastage

4. Power +

Water Consumption

5. Charges

for Supervision

6. Scaffoldings/Equipment

and Tools

7. Incidental

expense

8. Contractor

profit

OK, Lets take rate analysis of

plastering for data

Area = 10 sqm

Mix

ratio = 1:6

Thickness = 15mm - 0.015m

Rate

Analysis of Plastering

Step 1: Material calculation

Cement

calculation

Volume

of mortar = Area x thickness + (10% Extra for uneven surface)

Volume of mortar = (10 x 0.015) + 10% = 0.165cum

Dry

Volume of Mortar = 1.22 x Wet Volume of Mortar

So,

Dry Volume of Mortar = 1.22 x 0.165 = 0.2013 cum

Given a mortar mix ratio of 1:6 therefore, one part of cement is mixed with six

parts of sand

Volume of cement = 1/(1+6) = 0.142857 cum

Volume of cement = 0.2013 x 0.142857 = 0.0287 cum

Cement Required in weight = Volume x density

= 0.0287 x 1440 = 41.328

Cement Required in weight = weight in kg/50kg = 41.328/50 = 0.82 – 1 bags

Sand calculation

Volume of sand = 6/(1+6) = 0.8571 cum

Volume of sand = 0.2013 x 0.8571= 0.1725 cum

Sand Required in weight = Volume x density = 0.1725 x 1650 = 284.62kg

Sand Required in Cft = 0.1725 x 35.31 = 6.0909 cft (As we know that 1m3

= 35.31 CFT)

Also use plastering material calculation excel

sheet

Step 2: Labour

calculation

How much plastering can be done in a day?

|

Wall Area |

Wall height (noted for Scaffolding preparations) |

Window, door jambs and beam soffit |

Labour Required |

|

100 sqft |

<10ft |

nil |

1 mason, 1 helper |

|

100 sqft |

<10ft |

Yes |

1.25 mason, 1.25 helper |

|

100 sqft |

10ft |

Yes |

1 mason, 1 helper |

|

100 sqft |

10ft – 12ft |

nil |

1.5 mason, 1.5 helper |

|

100 sqft |

10ft – 12ft |

Yes |

1.5 mason, 1.5 helper |

The above data his prepared for average labour used at more than 10 construction

sites. Try to prepare your own labour usage

Also read: Labour

management in construction

Also read: Task

for an average skilled labour per day

From the above table, (10sqm – 107.6sqft)

We will take a 10 ft wall with no walls and door

jambs so we need 1 mason and 1 helper.

Step 3: Other Expenses

1. Power +

Water Consumption – 1.5%

2. Charges

for Supervision – 5%

3. Scaffoldings/Equipment

and Tools – 2%

4. Incidental

expense – 2%

5. Contractor

profit – 20%

Above percentage, his prepared for average labour used more than 10 construction sites.

Have a look at What is the cost of Cement Plastering per sqft, sqm, cft and cum?

Rate Analysis of Plaster Using Excel Sheet

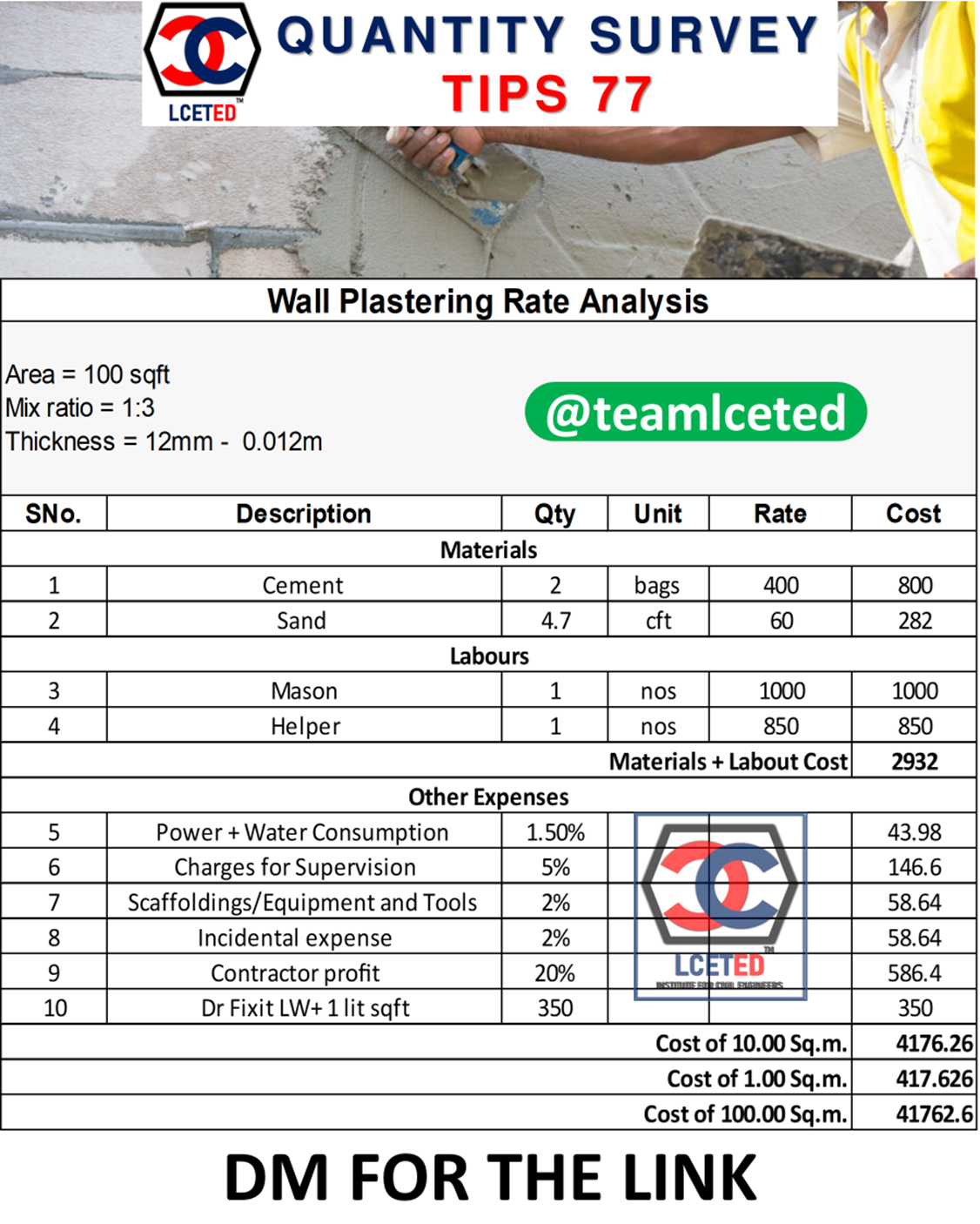

|

Wall Plastering Rate Analysis |

|||||

|

Area = 10 sqm |

|||||

|

SNo. |

Description |

Qty |

Unit |

Rate |

Cost |

|

Materials |

|||||

|

1 |

Cement |

1 |

bags |

400 |

400 |

|

2 |

Sand |

6.09 |

cft |

60 |

365.4 |

|

Labours |

|||||

|

3 |

Mason |

1 |

nos |

1000 |

1000 |

|

4 |

Helper |

1 |

nos |

850 |

850 |

|

Materials + Labout Cost |

2615.4 |

||||

|

Other Expenses |

|||||

|

5 |

Power + Water Consumption |

1.50% |

|

|

39.231 |

|

6 |

Charges for Supervision |

5% |

|

|

130.77 |

|

7 |

Scaffoldings/Equipment and Tools |

2% |

|

|

52.308 |

|

8 |

Incidental expense |

2% |

|

|

52.308 |

|

9 |

Contractor profit |

20% |

|

|

523.08 |

|

Cost of 10.00 Sq.m. |

3413.097 |

||||

|

Cost of 1.00 Sq.m. |

341.3097 |

||||

|

Cost of 100.00 Sq.m. |

34130.97 |

||||

Also Use: Plastering Calculator | Calculation of Materials For Plastering | SQFT | SQM

FAQ

What are the Specifications Used for Plastering Work in different countries?

Here are the lists of

plastering work specifications as per the Indian standards, British, American, and

New Zealand Standards

Indian Standard (BIS codes):

IS 8112 Specification for 43

grade OPC

IS 269 Specification for 33

grade OPC

IS 1489 Specification for

Portland Pozzolana Cement

IS 383 Specification for

coarse and fine aggregates for natural sources for concrete.

IS 1542 Specifications for

sand for plaster

IS 2645 Specifications for

integral cement waterproofing compound

British Standards:

BS EN 998-1:2016

This standard BS EN 998-1:2016

Specification for mortar for masonry is classified in these ICS categories: 91.100.10

Cement. Gypsum. Lime. Mortar

American Standards:

ASTM C 926 - Standard

Specification for Application of Portland Cement-Based Plaster

New Zealand Standards:

NZS 4251.1:2007 - Solid

plastering - Cement plasters for walls, ceilings and soffits

The material used for

plastering work should be tested as per specification.

What are the points to be considered while Plastering work Rate analysis?

1. Manpower wages + including their transportation

2. Labour Output per day

3. Material Required + wastage

4. Power + Water Consumption

5. Charges for Supervision

6. Scaffoldings/Equipment and Tools

7. Incidental expense

8. Contractor profit

What are the sequences of work to be done before starting the plastering work?

Before starting interior plastering work, interior brickwork should be completed. In external plastering work, you should first complete the perimeter brickwork of each floor. Exterior plastering work is always started from the top of the building and finished at the bottom, and ceiling plastering should be completed before wall plastering begins.

No comments:

Post a Comment