Inspection Checklist for Concrete Placement | Pre, Post and during

Placement

To achieve greater strength and durability of the structural inspection

of concreting works is important. So we need to make all the checks during the inspection of concrete as a checklist. The checklist will be the record of concrete

placement and quality control measures taken on the site

We should have 3 types of checklists for concreting work

1. Checklist for Equipment and Material Preparation

2. Checklist for During Construction

3. Checklist for After concreting

We have explained all three types of checklists below,

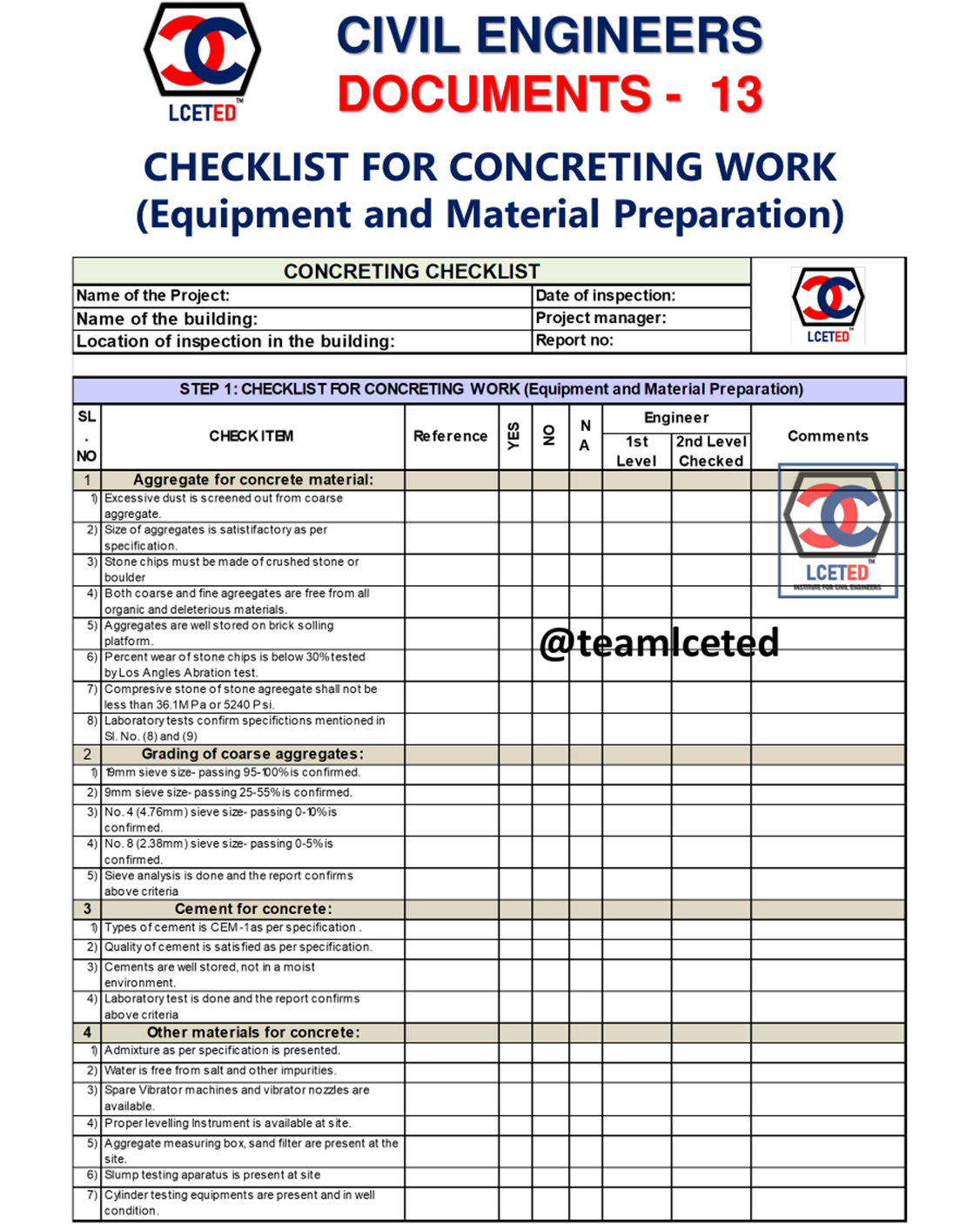

STEP 1: CHECKLIST FOR CONCRETING WORK (Equipment and Material Preparation)

1. Aggregate for concrete material:

A. Excessive

dust is screened out from coarse aggregate.

B. Size

of aggregates is satisfactory as per specification.

C. Stone

chips must be made of crushed stone or boulder

D. Both

coarse and fine aggregates are free from all organic and deleterious materials.

E. Aggregates

are well stored on a brick flat solling platform.

F. Percent

wear of stone chips is below 30% tested by Los Angles Abrasion test.

G. Compressive

stone of stone aggregate shall not be less than 36.1 MPa or 5240 Psi.

H. Laboratory

tests confirm specifications mentioned in Sl. No. (8) and (9)

2. Grading of coarse aggregates:

A. 19mm

sieve size- passing 95-100% is confirmed.

B. 9mm

sieve size- passing 25-55% is confirmed.

C. No.

4 (4.76mm) sieve size- passing 0-10% is confirmed.

D. No.

8 (2.38mm) sieve size- passing 0-5% is confirmed.

E. Sieve

analysis is done and the report confirms the above criteria

3. Cement for concrete:

A. Types

of cement are CEM-1 as per specification.

B. Quality

of cement is satisfied as per specification.

C. Cements

are well stored, not in a moist environment.

D. Laboratory

test is done and the report confirms the above criteria

Other materials for concrete:

A. Admixture

as per specification is presented.

B. Water

is free from salt and other impurities.

C. Spare

Vibrator machines and vibrator nozzles are available.

D. Proper

levelling Instrument is available at the site.

E. Aggregate

measuring box and sand filter are present at the site.

F. Slump

testing apparatus is present at the site

G. Cylinder

testing equipment is present and in good condition.

STEP 2: CHECKLIST FOR

CONCRETING WORK (During Construction)

1. Mix proportion is checked by the

engineer:

a) Volume

of concrete is estimated and the target time is set.

b) Admixture

is used as per design specification

2. Manpower for concreting:

a) Site Engineer are present while mixing and placing concrete.

b) Work

assistant at the mixing point is deputed to count and control the batch as per

concrete pouring slip and load count slip.

c) Manpower

for mixing is enough with respect to the volume of work

d) During

casting sufficient shuttering men are kept for constant watch on the prop.

3. Adequacy of materials:

a) Mixing

portions of cement, aggregates and sand are investigated as per design

specification.

b) Adequate

Materials such as cement, aggregates and sand are presented with respect to the volume of work.

c) Aggregates

are properly soaked

d) Aggregates

are well graded.

4. Preparation at the site for concreting:

a) For

bonding with old concrete, the edges of old concrete are to be broken to give a

firm bonding.

b) Grouting

is used for construction joints. Electrical conduit is ensured in the proper place.

c) Rain

protection is arranged. Clear covers are monitored before placing concrete.

d) Casting

sequences are decided as per the consent of the engineer in charge.

5. Adequacy of equipment:

a) Chutes, and concrete buckets are cleaned and ready for use.

b) Adequate

Vibrator nozles are checked and ready for use.

c) Tower

crane for vertical lifting is provided.

d) Thickness

checking device is provided.

6. Mixing of Concrete:

a) Measured

quantity of materials as per proportion are dumped in the drum of mixture

machine.

b) Mixing

is executed with the required quantity of water for a period of not less than 2

minutes after all materials including the water are in the drum.

c) Proper

water-cement ratio is ensured by measuring slump as mentioned below:

a. Footing, pile cap, mass concrete 2" maximum

b. Precast pile, column, beam, slab 2.5" maximum

c. Ready mix concrete (with admixture) 4.0" maximum

7. After mixing concrete:

a) Workability

of concrete is adequate (slump is proper).

b) Cubes/

Cylinders are taken from the mixing for testing.

c) Slump

test is conducted and found OK.

8. Placing of concrete:

a) Water

is sprayed on the surface of the shutter/ steel shutter.

b) Concrete

is placed within 30 minutes after mixing the water.

c) Height

of free fall concrete is within 3 feet.

d) Concrete

is layed from one end, then continuously proceeded to the other end.

e) Fresh

concrete is deposited against concrete which is in position within 45 minutes.

f) Thickness

is checked at 3’-0’’ interval over the concrete slab.

g) Frequent

movement of labours/others over reinforcement is avoided during casting. Use of

plain sheet as a walkway for carrying concrete at the place.

h) During

casting, immediate remedial measures are taken in case props get loosened.

Compaction of Concrete:

a) For

beam and column, concrete compaction is done properly by the vibrator.

b) Compaction

is done within 15 minutes after the fresh concrete is placed in position.

c) Vibrating

is stopped as soon as the laitance of mortar appears on the surface. (Excessive

vibration segregates the mix.)

d) Vibrating

is executed properly in the vertical placement of the vibrator.

e) Vibrating

is executed without touching the re-bar.

f) Proper

surface vibration of slab surface with thick & plain wooden plank.

STEP 3: CHECKLIST FOR

CONCRETING WORK (After concreting)

a)

Movement

over a concrete surface is avoided within 24 hours.

b) Concrete surface is kept wet with water till

the removal of formwork.

c)

Keys in the

column-lift are provided for subsequent concreting in the proceeding days.

Click to download Inspection and Quality Work Checklist for Concrete Placement

Good information ♥️

ReplyDeleteTo fulfill your dream homes with the best technology and designs

ReplyDeletehome construction in bangalore