ACI Concrete Mix Design | American Concrete Institute (ACI) Method

Objective

To design a concrete mix by

ACI method for crushing strength of 150 mm cubes at 28 days is 20 MPa and slump

is 50 mm.

Theory and Scope

The absolute volume

procedure as recommended by the ACI mix proportioning method is used for

determining the proportions of the

ingredients for the concrete mixture. The method is suitable for normal and heavyweight concretes having a maximum

28-day cylinder compressive strength of 45 MPa and a workability (slump) range of 25 to 100 mm; the values generally

used in the applications are listed in Table below. The ACI method presumes that the workability of a mix with a given maximum size of well-graded aggregate (i.e., an aggregate with suitable particle shape and the grading)

is dependent upon the water content, the amount of entrained air and certain chemical admixtures, but is

largely independent of mix proportions, particularly the amount of cementing material. Therefore, ACI has

provided a table relating nominal maximum aggregate size, air entrainment and desired slump to the required

mixing water quantity.

In the ACI method, the bulk

volume of coarse aggregate per unit volume of concrete is estimated for

the maximum size of coarse aggregate and

fineness modulus of sand. The water-cement ratio is determined as in other methods to satisfy both strength and

durability requirements. The air content in concrete is taken into account in calculating the volume of fine

aggregate.

Apparatus

Sieve sets for finding maximum

nominal size and fineness modulus of coarse and fine aggregates respectively; Weighing balance; Trowels; Tamping bar;

Moulds, Universal compression testing machine; Graduated cylinder; Slump cone apparatus and Buckets.

Procedure

Step 1: Perform

the sieve analysis of both the fine and coarse aggregates to determine the maximum

nominal size of coarse aggregate and fineness

modulus of fine aggregate. Determine the unit weight, specific gravities, and absorption capacities of both

the aggregates.

Step 2: If

the workability in terms of a slump is not specified for a particular job; select

an appropriate value from the Table below

Slump ranges for specific applications (after ACI, 2000)

|

Types

of Construction |

Maximum

Slump, mm |

Minimum

Slump, mm |

|

Reinforced

foundation walls and footings |

75 |

25 |

|

Plain

footings, caissons, and substructure walls |

75 |

25 |

|

Beams

and reinforced walls |

100 |

25 |

|

Building

columns |

100 |

25 |

|

Pavements

and slabs |

75 |

25 |

|

Mass

concrete |

75 |

25 |

The maximum slump may be increased 25 mm for consolidation by

hand, i.e., rodding, etc.

Step 3: Estimate the mixing

water required for non-air-entrained concretes and entrapped air content from the Table

below

Approximate requirements of mixing water for

non-air-entrained concrete (after ACI 211.1 and ACI 318)

|

Slump, mm |

Mixing water quantity1,

kg/m3 |

|||||||

|

Specified nominal maximum size of aggregate (after CSA A23.1)

(mm) |

||||||||

|

10 |

14 |

20 |

28 |

40 |

562 |

802 |

1502 |

|

|

25 – 50 (Stiff-plastic) |

207 |

199 |

190 |

179 |

166 |

154 |

130 |

113 |

|

75 – 100 (Plastic) |

228 |

216 |

205 |

193 |

181 |

169 |

145 |

124 |

|

150 – 175 (Flowing) |

243 |

228 |

216 |

202 |

190 |

178 |

160 |

- |

|

Approximate amount of

entrapped air, per cent |

||||||||

|

All |

3.0 |

2.5 |

2.0 |

1.5 |

1.0 |

0.5 |

0.3 |

0.2 |

The table gives the maximum water content for reasonably well-shaped crushed aggregate.

The slump values are based on the slump made after the removal

of particles larger than 40 mm by wet screening.

Step 4: Determine the

target mean compressive strength of concrete at 28 days, ft by using the

ft

= fck + k (=1.65)S

where fck is the characteristic compressive

strength at 28 days, and S is the standard deviation.

Step 5: Determine the water-cement ratio from Table below

or Fig. below for the target mean strength computed in Step 4.

Relationship between water-cement ratio and

compressive strength of concrete

|

Compressive strength at 28 days, MPa |

Water-cement ratio by weight |

|

40 |

0.42 |

|

35 |

0.47 |

|

30 |

0.54 |

|

25 |

0.61 |

|

20 |

0.69 |

|

15 |

0.79 |

Maximum permissible water-cement ratios for concrete under severe exposure

|

Type

of Structure |

Continuously

wet structure exposed to frequent freezing

and thawing |

Structure

exposed to seawater or sulphates |

|

Thin

section (railings, curbs, sills, ledges, ornamental work) and sections with

less than 25 mm cover over steel |

0.45 |

0.40 |

|

All

other structures |

0.50 |

0.45 |

Step 6: Calculate

cement content from the water content and water-cement ratio determined in

Steps 3, 4 and 5, respectively, for the required strength and durability.

Step 7: Estimate

the coarse aggregate content from the Table below for the maximum nominal size of

the coarse aggregate and fineness modulus of sand.

Step 8: Determine

the content of fine aggregate by subtracting the sum of volumes of the coarse aggregate,

cement, water and entrained air from the unit volume of concrete.

Step 9: Fix

the concrete mix proportions for the first trial mix or trial mix no. 1. Make

suitable adjustments for moisture in the aggregates.

Relation between water-cement ratio and compressive strength of concrete

Bulk volume of coarse

aggregate per unit volume of concrete for different fineness moduli of fine aggregate

(Adapted from ACI 211.1)

|

Nominal

maximum size of aggregate (after CSA A23.1), mm |

Bulk volume of oven-dry-rodded coarse

aggregate, m3 Fineness modulus of fine aggregate

|

|||

|

2.40 |

2.60 |

2.80 |

3.00 |

|

|

10 |

0.50 |

0.48 |

0.46 |

0.44 |

|

14 |

0.59 |

0.57 |

0.55 |

0.53 |

|

20 |

0.66 |

0.64 |

0.62 |

0.60 |

|

28 |

0.71 |

0.69 |

0.67 |

0.65 |

|

40 |

0.75 |

0.73 |

0.71 |

0.69 |

|

56 |

0.78 |

0.76 |

0.74 |

0.72 |

|

80 |

0.82 |

0.80 |

0.78 |

0.76 |

|

150 |

0.87 |

0.85 |

0.83 |

0.81 |

Step 10: Measure

the workability of the trial mix in terms of slump using only as much water as

is needed to reach the desired slump (but

not exceeding the permissible w/c ratio). Carefully observe the mix for freedom from segregation and bleeding and

its finishing properties. Use the fresh concrete for unit weight, yield and air content.

Step 11: Recalculate

the mix proportions keeping the free water–cement ratio at the pre-selected

value; this will comprise trial mix no.

2. In addition, design two more trial mixes no. 3 and 4 with the water content same as trial mix no. 2 and varying

the free water–cement ratio by ±10 per cent of the preselected value.

Step 12: Cast

three 150 mm cubes for each trial mix and test them after 28 days of moist curing.

If required, a similar number of cubes may

be prepared and tested for early strength,.

Step 13: Analyse

mix nos. 2 to 4 for relevant information, including the relationship between

compressive strength and water–cement

ratio. Using this information compute the water-cement ratio required for the mean target strength. Recalculate the mix

proportions for the changed water–cement ratio taking water content as the same as that

determined in trial no. 2.

For field trials, produce the

concrete by the actual concrete production method used in the field.

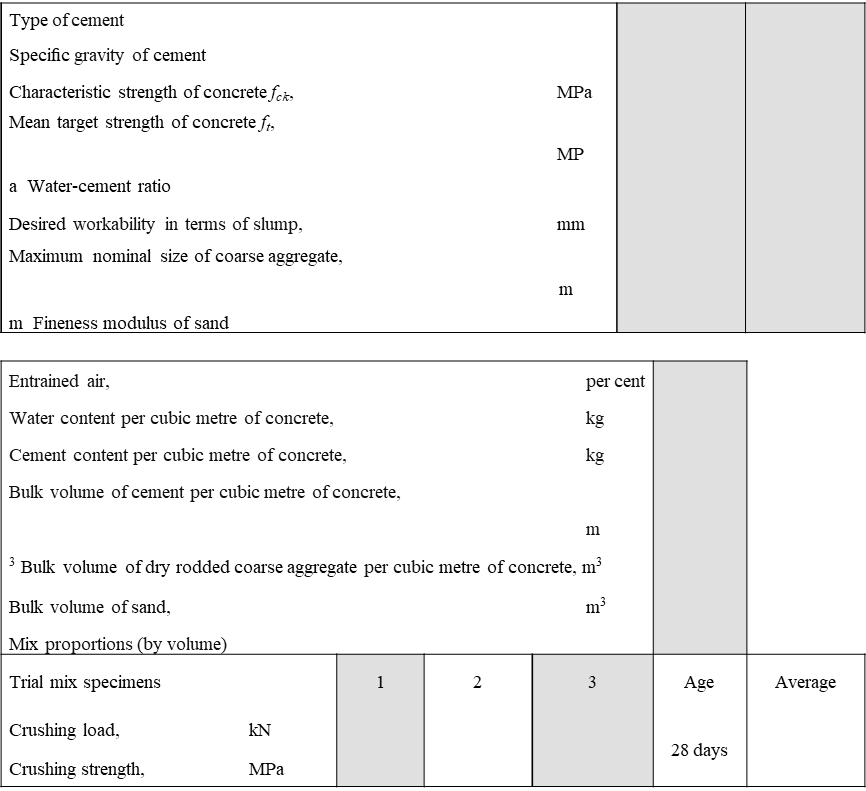

Observations and Calculations

The compressive strength of concrete

is……. MPa.

This mix is suitable/it needs

revision.

The mix proportion is ……………..

Precautions

1. For calculating the

water-cement ratio, the surface moisture should be added to the water mixed

in concrete.

2. In choosing the strength

required for a particular purpose, allowance must be made for the inevitable variation in the strength of the test cubes. From

the specified minimum strength, the target means strength is estimated according to the degree of

control to be exercised, using information obtained from experience.

3. Slump test should be

completed within 30 minutes.

4. Contents should be

weighed accurately.

5. The inside of the cube

should be oiled to prevent the mortar from adhering to the sides of the mould.

6. The ambient temperature

at which cubes are prepared should be between 25 and 29°C.

Discussion

The method assumes that the

workability of a concrete mix is dependent only on the water content in the mix. The water content decreases with the

increase in the maximum nominal size of the coarse aggregate. The fraction of coarse aggregate itself decreases

with the increase of fineness modulus of fine aggregate, i.e., the coarser the sand lower will be the bulk volume

of dry coarse aggregate required for the mix. However, the coarse aggregate content increases with the increase

in the maximum nominal size of aggregate.

REFERENCES

ACI 211.1-91: Standard Practice for Selecting

Proportions for Normal, Heavyweight and Mass

Concrete, American Concrete Institute, Farmington Hills, Michigan, 1991.

ACI 211.4R-93: Guide for Selecting Proportions for

High-Strength Concrete with Portland Cement and Fly Ash, 1993.

ACI 211.5R-96: Guide for Submittal of Concrete

Proportions, American Concrete Institute, 1996.

ACI 211.3R-97: Guide for Selecting Proportions for

No-Slump Concrete, 1997.

ACI 211.2-98: Standard Practice for Selecting

Proportions for Structural Lightweight Concrete, 1998.

ACI 301-99: Specifications for Structural Concrete, 1999.

ASTM C39: Compressive Strength of Cylindrical Concrete

Specimens.

ASTM C617: Capping Cylindrical Concrete Specimens.

ASTM C192: Making and Curing Concrete Test Specimens in

the Laboratory.

The Better Co is a home construction company which helps you build your dream home and do your home interiors on one platform construction possible within your budget.

ReplyDeleteconstruction cost calculator

Great at representing businesses. https://www.LosAngelesCivilLitigationLawyer.com

ReplyDeleteLawyer attorneys use wisdom, compassion, and courage consistently daily. click site

ReplyDelete