British

DoE Concrete Mix Design

Objective

To design a concrete mix in accordance with the British

DoE mix design method.

Theory and Scope

The British DoE method can

be applied to produce designed concrete, using cement and aggregates

which conform to the relevant British

Standards. The method is suitable for the design of normal concrete having 28-day compressive strength as high as 75 MPa

for non-air-entrained concretes. The method is also suitable for the design of concretes containing fly ash

and GGBFS.

The mixes are specified by

the mass of the different materials contained in a cubic metre of fully

compacted fresh concrete. The method is

based on the following four criteria:

1. The volume of freshly mixed concrete

equals the sum of the absolute volumes of its constituent materials, i.e., the water, cement, air content and

the total aggregate. The method, therefore, requires that the absolute densities of the materials be known

in order that their absolute volumes may be calculated.

2. The compressive strength class of concrete depends

on

a. The free water–cement ratio.

b. The type of coarse aggregate, i.e., whether the

aggregate is crushed or uncrushed (gravel).

c. The type of cement, i.e., whether the cement is

normal (ordinary) Portland cement or combined cement.

3. The consistency (workability) of concrete

depends primarily on

a. The free water content.

b. The type of fine aggregate and, to a lesser degree, the type of coarse aggregate.

c. The nominal upper (maximum) size of coarse aggregate.

4. The consistency (workability) depends

secondarily on

a. The fraction of the fine aggregate is a proportion of

the total aggregate content.

b. The grading of the fine aggregate.

C. The free water–cement ratio.

Based on the method, the

preliminary or trial mixes are made and desired properties of the trial mixes

are checked; suitable adjustments are

made to produce concrete possessing specified properties both in fresh and hardened states with the maximum overall

economy.

Apparatus

Sieve sets for finding

maximum nominal size, and gradings of coarse and fine aggregates; Weighing

balance; Trowels; Tamping bar; Moulds;

Universal compression testing machine; Graduated cylinder; Slump cone apparatus and Buckets.

Procedure

Step 1:

Perform sieve analyses of both the fine and coarse aggregates available to

determine:

a. The nominal upper

(maximum) size of coarse aggregate The designations of coarse aggregate are established from the nominal lower and

upper sieve sizes for the particular aggregates, the lower size being stated

first. For example, an aggregate of a maximum nominal size of 10 mm is designated as 4/10. The maximum aggregate

sizes recommended are 10 mm; 20 mm and

40 mm.

b. Gradings of fine and coarse aggregates.

c. Gradings zone of fine aggregate.

If necessary, combine two

or more different size coarse aggregate fractions so that the overall grading of coarse aggregate conforms

to the desired grading for the particular nominal maximum size of aggregate.

Step 2:

Determine the absolute densities, specific gravities, and absorption capacities

of both the coarse and fine aggregates.

Also, determine the specific gravity of overall aggregates in the saturated

surface dry condition.

Step 3:

Select the target consistency (workability) of fresh concrete in terms of slump

class for the normal working range of

zero to 200 mm. Where consistency other than slump is specified it is

recommended that a relationship between

the two is established.

Step 4:

Estimate the strength margin factor and the standard deviation for calculation

of the target mean corresponding to the

28-day characteristic strength specified. The margin takes into account

the degree of safety required for the

strength; it is either specified or calculated for a given proportion of defectives. The statistical standard

deviation takes into account the conformity rules (quality control) during production. These quantities

are different for cylinders or cubes.

Note: EN:206

classifies concrete strength in terms of 28-day characteristic strengths on the

basis of cylinders and cubes, e.g., C25/30,

where the first number is the strength of 150 mm (diameter) × 300 mm (high) cylinder and the second number is the 150

mm cube strength. However, it should not be presumed that by giving both cube and cylinder strengths,

a particular relationship is being assumed for purposes of conversion for concrete design or control.

Step 5: Obtain

the target mean strength by adding a margin to the stipulated characteristic strength

and statistical standard deviation.

If air entrainment is specified,

calculate the artificially raised modified target mean strength.

Approximate compressive

strength of concrete with a water-cement ratio as 0.5

Step 6: Select the maximum free water–cement ratio

which will provide the target mean strength for concrete made from the given types of coarse aggregate

and cement as follows: For the given type of cement and aggregate, the

compressive strength at the specified age corresponding to the reference water-cement ratio of 0.50 is obtained from

Table above For example, when normal

Portland cement and uncrushed aggregate are used, the compressive strength is

43 MPa at 28 days. With this pair of

data (43 MPa and water-cement ratio = 0.50) as a controlling or reference point, a strength versus water-cement ratio

curve is located in Fig. below In this particular case, it is the fourth

(dotted) curve from the top of Fig. below passing the controlling point. Using

this curve, the water-cement ratio is

determined corresponding to the computed target mean strength. In case an existing curve is not available that passes

through the controlling point, the curve is interpolated between two existing curves in Fig. below

Variation of compressive strength

with water–cement ratio (DoE)

Compare this water-cement

ratio with the maximum water-cement ratio specified for the durability from

the Table below and adopt the lower of

the two values. The maximum water-cement ratio based on durability considerations includes a set of exposure classes

related to different mechanisms of deterioration. Exposure class XO exists on its own and there are no

requirements for the water-cement ratio or the minimum cement content.

Minimum cement content and maximum

water–cement ratio for different exposures

Abbreviations: w = with; wo = without; s = de-icing salt

BS EN:2306-1

does not contain abrasion classes

Note:

For a concrete designed using EN: 206 specifications for durability, the EN:206

specifications allow to count of the

proportion (k) of addition in the combination with cement towards satisfying

specified limits for minimum cement

content and maximum water–cement ratio, rather than just the cement content.

Since generally the presence of Type 2

(pozzolanic or latent hydraulic) addition reduces the heat of hydration and

improves the durability of a mix. Here,

the factor k called the efficiency or strength factor of the addition refers to

relative strength of addition with

respect to the cement.

Approximate water content required for target

consistency (Workability)

Step 7: Select the approximate free water content

from the Table above, which will provide the target consistency (specified in terms of a slump or flow diameter

or Vee-Bee time) for the concrete made with the given fine and coarse aggregate types and nominal

upper size of coarse aggregate.

When the coarse and fine aggregates used are of different

types, the water content is estimated by the expression given by Eq. (below).

W =

(2WF/3)+(WC+3)

Where,

Wf = water content appropriate to type of fine aggregate.

Wc = water content appropriate to type of coarse

aggregate.

If the free water content has been determined for target

consistency, adjust it for the specified air entrainment, and further adjust if the water reducing admixture is specified.

Step 8: Determine minimum

cement content by dividing the free water content obtained in Step 7 by the

free water–cement ratio obtained in Step

6.

Cement content (kg/m3) = (Water content/water-cement ratio)

a. Compare the computed cement

content with the maximum cement content which is permitted. If the calculated cement content is higher than the

specified maximum, then the target strength and target consistency (workability) cannot

be achieved simultaneously with selected materials. In such a situation, the process is repeated by changing

the type of cement, the type and the upper size of the aggregate.

b. Compare the computed

cement content required for target strength with the minimum cement content which is specified for durability;

adopt the greater of the two in the concrete.

Thus the cement content is the minimum given by a free

water-cement ratio that is low enough to

provide the target strength and durability.

Step 9: Determine

the free water content which is available to react with the cement; it is the sum

of (a) the added water; (b) the

surface water of the aggregates and (c) the water content of admixtures less (d) the water absorbed by the

aggregate during the period between the mixing and the setting of the concrete.

Step 10: Divide

the free water content by the cement content used in the concrete to obtain a

modified free water–cement ratio.

Estimated

wet density of fully compacted concrete (DoE)

Step 11:

Compute the total absolute volume of aggregates as follows:

The total aggregate content

(kg/m3) can be computed from the wet density of concrete obtained from Fig, above

The wet density of concrete depends on the specific gravity of overall aggregates in the saturated surface dry

condition.

Alternatively, the absolute

volume fraction of the aggregate is calculated by subtracting the proportional

volumes of the free water and cement from a unit volume of concrete using Eq. (below).

Absolute volume of aggregates

= 1 – (c/1000Sc) – (W/1000)

where C and W are the

cement and water contents, respectively, and Sc is the specific gravity of cement particles. Therefore,

Total aggregate content (kg/m3) =

(1000Sa) x absolute volume of aggregates (2)

where Sa is the specific

gravity of aggregate particles. If no information is available Sa may be taken at 2.6 for uncrushed aggregate and 2.7 for

crushed aggregate i.e. curves A and B can be used.

Step 12: Determine the fine

and coarse aggregate contents as follows:

(a) Obtain the percentage of fine aggregate from Fig. below expressed as a percentage of total aggregate that will provide the target consistency of the fresh concrete

to be made with the given grading of fine aggregate, the nominal upper size of coarse

aggregate and the free water-cement ratio

obtained in Step 10.

(b) Calculate the content of coarse aggregate from the

total aggregate content obtained in Step 8 as follows:

Coarse aggregate content (per cent) = 100 – content of aggregate (percent)

(C) Divide the coarse aggregate further into different size

fractions. Coarse aggregate fractions listed

in the Table above can be used as a general guideline.

Recommended

proportions of fine aggregate for different grading zones (DoE)

Proportions

of different sizes of coarse aggregates

|

Aggregate

size range (mm) |

(2.36

/4) - (4 /10) |

(4

/10) - (10 /20) |

(10

/20) -(20 /40) |

|

Type-I |

33 |

67 |

– |

|

Type-II |

18 |

27 |

55 |

Step 13:

Determine the concrete mix proportions for the first trial mix or trial mix no.

1. Measure the workability of the trial

mix in terms of a slump; carefully observe the mix for freedom from segregation

and bleeding and its finishing

properties. If the slump of the first Trial mix is different from the

stipulated value, adjust the water

and/or admixture content suitably to obtain the correct slump.

Step 14:

Make adjustments for aggregate moisture and determine final proportions. Since

aggregates are batched on an actual weight

basis, adjust the amount of mixing water to be added to take into account the aggregate moisture.

Step 15: Recalculate

the mix proportions keeping the free water-cement ratio at the pre-selected value;

this will comprise Trial mix no. 2. In

addition formulate two more trial mixes no. 3 and 4 with the water content same as Trial mix no. 2 and varying

the free water-cement ratio by ±10 per cent of the preselected value.

Step 16: Test

the fresh concrete for unit weight, yield and air content. Prepare trial mix

and cast three 150 mm cubes and test

them after 28 days of moist curing.

Step 17: Analyse

mix nos. 2 to 4 for relevant information, including the relationship between

compressive strength and water–cement ratio.

Compute the water-cement ratio required for the mean target strength using the relationship. Recalculate the mix proportions

for the changed water–cement ratio keeping water content at the same level as that determined

in trial no. 2.

For field trials, produce the concrete by the actual

concrete production method used in the field.

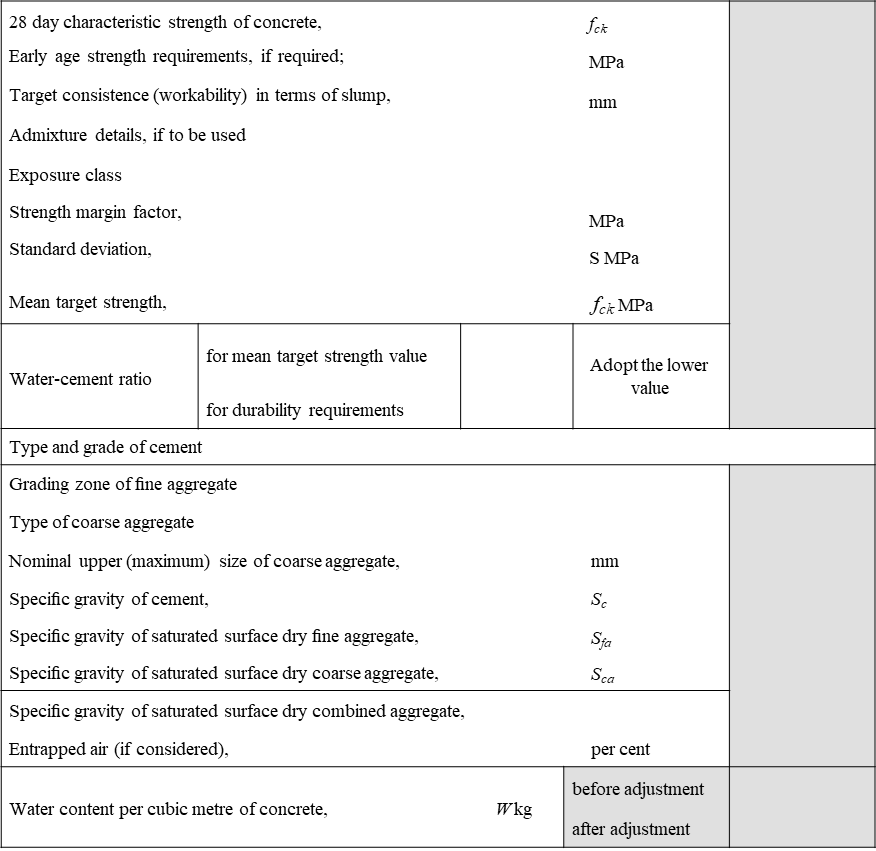

Observations and Calculations

The compressive strength of concrete mix is………..

The designed mix is suitable/it needs further revision

The mix proportions are…………………

Precautions

The slump test, cube casting, curing and testing should

be done according to the specifications.

The fresh concrete should be carefully observed for

freedom from segregation and bleeding, and finishing properties.

Discussion

EN:206 exerts relatively

little influence directly on the process of design of concrete mixtures which is

a key part of concrete production.

However, it does of course have a considerable indirect effect through the requirements for specification and conformity.

An exposure class which

requires the greatest resistance in the form of the lowest water-cement ratio

along with the highest minimum cement

content and the highest concrete strength class is selected. However, the minimum cement contents are independent of

the type of cement used. EN:206 specifies design margins in the minimum cement content of minus 10 kg and in

maximum water-cement ratio plus 0.02 in trial batch tests.

The free water content

which is available to react with the cement is the sum of (a) the added water;

(b) the surface water of the aggregates

and (c) the water content of admixtures less than (d) the water absorbed by the aggregate during the period between the

mixing and the setting of the concrete.

Target air content of fresh

concrete For non-air entrained concrete, air content is not specified but

entrapped air is as usual considered in the design for EN:206 concrete. For air entrained concrete, EN: 206 specifies

minimum total air content with a maximum

total air content being 4 per cent higher than the specified minimum.

Are there emperical formulas that can be used instead of these plots? I'm trying to apply these in a programming script

ReplyDelete