In This Article, We

Explained About BBS - What Is Bar Bending Schedule (BBS), Things To Know Before Preparing a Bar Bending

Schedule, How To

Prepare a Bar Bending Schedule on excel, and the Advantages of Using BBS

What is Bar Bending Schedule (BBS)?

Bar Bending Schedule is a comprehensive list of bent

reinforcement bars given in any structural concrete element.

Bar

Bending Schedule Contains size, shape, location, mark, type, length, number,

and bending details

Bar

bending is the process of cutting the reinforcement steel bar in the shape of a

desired according to the structural drawing provided by the structural engineer

for various structural elements such as slab, column, beam, and foundation.

A

bar bending table allows site engineers to estimate the required dimensions of

bars of different diameters used in construction. This allows the engineer to

verify the reinforcement work done by the contractor.

Things to Know Before

Preparing Bar Bending Schedule

1. What are

the various diameters of the steel bars used in various structures?

6mm, 8mm, 10mm, 12mm, 16mm,

20mm, 25mm, 28mm, 32mm, 36mm, 40mm

2. What is

the standard length of a steel bar?

40 feet or 12m long

3. Unit

Weight of Steel Bar Formula | Steel weight and formula for unit weight of steel

calculation

Weight of Steel Bar

= D²/162 kg/m in Kg and Length ‘L’

in m

Weight of Steel Bar

= D²/533 kg/feet in Kg and Length

‘L’ in foot

4. Click to

read: How

to Calculate Weight of Steel Bars in meters

5. Click to

read: How

to Calculate Weight of Steel Bars in feet

e. Diameter of

Reinforcement Bars (in inches)

6. How many pieces are in a TMT bar

bundle? TMT Weight per Bundle?

Note: The length of the TMT Steel rod will be 12 meters or 40

feet.

|

TMT SIZE |

TMT RODS PER BUNDLE |

TMT WEIGHT PER BUNDLE |

|

8mm (1 Bundle) |

10 |

47 Kg |

|

10mm (1 Bundle) |

7 |

53 Kg |

|

12mm (1 Bundle) |

5 |

53.4 Kg |

|

16mm (1 Bundle) |

3 |

56.88 Kg |

|

20mm (1 Bundle) |

2 |

59.2 Kg |

|

25mm (1 Bundle) |

1 |

46.2 Kg |

|

32mm (1 Bundle) |

1 |

75.72 Kg |

HOW

MANY NUMBERS OF RODS PER BUNDLE? HOW TO CALCULATE IT?

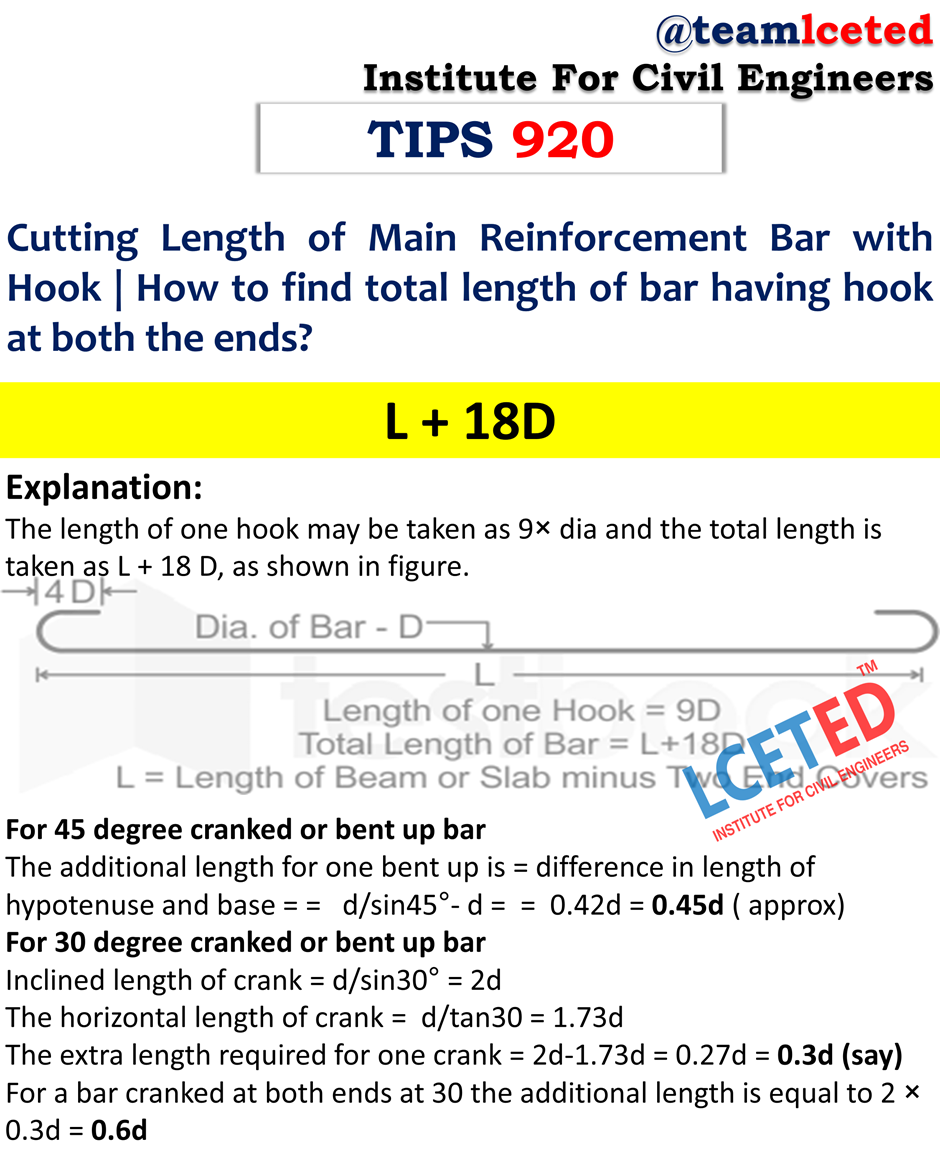

7. Cutting Length of Main

Reinforcement Bar with Hook | How to find the total length of the bar having a hook at

both ends?

8. How is bar

bend length calculated?

KNOW

HOW TO CALCULATE THE CUTTING LENGTH OF BENT UP BARS

9.

Overlapping

The standard length of Rebar is 12m. Suppose the height of the column is

20 m. To purvey this requirement, two bars of length 12m and 8m are overlapped

(joined) with overlap length.

Overlap Length for compression members (columns) 50d

The Overlap Length for tension members (beams) = 40d

[Where d is the Diameter of the bar]

10. Bend

Deduction

The Bend length calculation is different for Cranked bars (bent up bars)

and bends at corners. The bars are usually cranked in Slabs and bars are bent

at corners in Stirrups or ties.

The formulae for bend deduction are

1. For 45° bend = 1 x d

2. For 90° bend = 2 x d

3. For 135° Bend = 3 x d

4. For 180° bend = 4 x d

11. Concrete Cover: All

You Want to Know About Cover Blocks Used In Construction

12. How do I

format a BBS in Excel? | Format for Bar Bending Schedule in Microsoft

Excel | BBS SHEET | BBS EXCEL SHEET | Bar bending schedule BBS excel sheet

How to prepare bar bending schedule?

Preparation of Bar Bending Schedule

Step 1: Identification of

Members (Steel Bars)

Step 2: Count the Number of

bars

Step 3: Calculate the

length of the Reinforcement bars

Step 4: Calculate the unit

weight of the Reinforcement Bar

Step 5: Calculate the

Weight of a particular Shape of the Bar

Step 6: Calculate the Total

Weight of bars needed

What is the data required for preparing

BBS?

• Bar number/Bar Mark Reference

• Bar shape

• Diameter

• Spacing

• Length of bar

• Cutting Length

• Number of bars

General Guidelines To Be Followed In

Preparing BBS

1.

The bars should be grouped together for each structural unit, e.g. beam,

column, etc.

2.

In a building structure, the bars should be listed floor by floor.

3.

For cutting and bending purposes schedules should be provided as separate A4

sheets and not as part of the detailed reinforcement drawings.

4.

The form of bar and fabric schedule and the shapes of bar used should be in

accordance with BS 8666.

5.

It is preferable that bars should be listed in the schedule in numerical order.

6.

It is essential that the bar mark reference on the label attached to a bundle

of bars refers uniquely to a particular group or set of bars of defined length,

size, shape and type used on the job.

7.

This is imperative as a bar mark reference can then point to a class of bar

characteristics. Also, this helps steel fixers and labourers keep track of the

type and number of bars needed to complete a certain work.

ADVANATAGES OF USING BBS

BBS helps to estimate the total quantity of

steel required for the construction of building or structure. It helps to quote

for tender the cost incurred by steel.

Finding the cutting length and bending length

in reinforcement detailing improves the quality of construction and minimize

the wastage of steel, making an economic construction.

With the help of reinforcement drawings,

cutting and bending can be done at the factory and transported to the site.

This increases faster construction and reduces the total construction cost.

For site engineers, it becomes easy to verify

the cutting length and bending length of the reinforcement before placing the

concrete.

Nice article, All BBS Formulas with example Download from here: Stirrups Cutting Length Formula

ReplyDelete