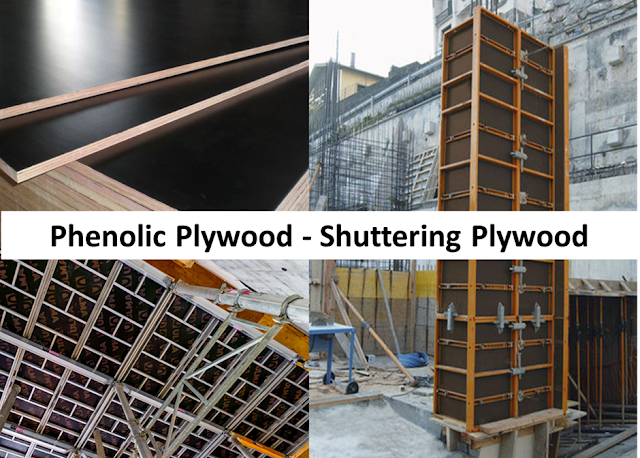

In this article, we will look at what phenolic plywood is, how it is made, and its application in the construction industry.

Phenolic Plywood Also known

as Phenolic Film-Faced Concrete Shuttering Plywood, it is widely used in the

construction industry to create wood moulds used for casting concrete when

constructing concrete slabs and columns of buildings. One of the main advantages

of using film-faced plywood for concrete moulding is that these boards are

completely water-resistant, the concrete does not stick to their surface, and

these plywood sheets can be reused after the concrete casting process is

complete.

How phenolic plywood is made

Generally, phenolic plywood

is waterproof type plywood with a phenolic film on its surface. In the final

stage of the manufacturing process, a phenolic film is applied to the surface

of the plywood. This is why it is also called Film Faced Plywood.

Manufacture Process of Phenolic Plywood

Step

1:

Good quality timber logs acquired from hardwoods are used as raw material.

Step

2:

Slices of wood veneers are obtained from these logs. For doing this, the timber

logs are mounted on a machine, that rotates the logs about their longitudinal

axis, while a cutter peels off layers from the log. These layers are the

veneers.

Step

3:

The veneers are graded according to quality, and stacked upon each other.

Step

4:

Synthetic phenolic resin, made from phenol-formaldehyde, is evenly spread over

the veneers to glue them together.

Step

5:

The multiple layers of veneers (plies), arranged in alternating grain patterns,

are then hot-pressed to form a strong and permanent bond.

Step

6:

Preservative treatment is carried out on the plywood by adding appropriate

chemicals.

Step

7:

At the final stage, a very thin film of phenolic resin is applied to the

surface of the plywood. This film is made by soaking and saturating a paper in

phenolic resin. Once the resin has hardened, the paper becomes hard and the

film is ready. The film is then hot pressed and melted onto the surface of the

plywood, to achieve a smooth, hard finish.

Step

8:

Glossy plywood is now ready for quality testing and transporting

The outer glossy surface of

most phenolic plywood is usually dark red, although it can also be found in

dark brown or black.

It is worth noting that

decorative laminates are made using a similar process. For laminates, brown

handmade paper soaked in phenolic resin and decorative paper soaked in

transparent melamine resin are hot-pressed under high pressure, forming

decorative laminate sheets that can be applied to the plywood as an overlay.

Quality tests for Phenolic plywood:

Like marine-grade plywood,

quality tests for phenolic film faced shuttering plywood include

water-resistant testing, during which sample pieces of plywood are immersed in

boiling water for 72 hours, then removed and cooled in Coldwater. Still, wet

pieces are tested for strength and make sure the outer phenolic layer does not

deteriorate in any way.

The Indian Standard Specification

Document for Concrete Shuttering Plywood is described in IS:4990.

Manufacturing companies that meet the

recommended standards can obtain a certificate from the BIS (Bureau of Indian

Standards) and then qualify to place a reliable ISI seal on their plywood

sheets.

Quality tests for Phenolic

plywood:

Similar to Marine grade

plywood, the quality tests for phenolic film faced shuttering plywood also

include water-resistance tests during which sample pieces of the plywood are

submerged into boiling water for a period of 72 hours, and then removed and cooling by plunging into cold water. The still wet pieces are then tested for

strength and also checked so as to confirm that the outer phenolic layer has

not deteriorated in any manner.

The Indian Standard quality

specification for Concrete Shuttering plywood is detailed in document IS:4990.

Manufacturing companies who meet the prescribed quality standards can obtain a

certificate from BIS (Bureau of Indian Standards), and then become eligible to

put the trusted ISI mark on their plywood sheets.

Important properties of Phenolic

plywood:

Durable: Concrete

casting process involves alternative wet and dry conditions. The plywood must

be durable to withstand these conditions.

High in Strength:

Concrete is made by mixing cement, sand and crushed stone together with water.

While the concrete cures and becomes hard it exerts a force on the shuttering

plywood mould. So the plywood has to be strong to withstand these forces.

Reusable: The

use of phenolic film fastened concrete shuttering plywood is advantageous

because once the concrete casting process is complete the plywood shutters can

be removed and these sheets reused elsewhere. To make this happen, however, the

plywood sheets must be handled with care when setting up and removing the form

so that they are reusable enough.

Shiny,

glossy surface: The phenolic film provides the plywood with

a very smooth glossy surface. This is a very useful characteristic in the case

of concrete shutter work because the concrete does not stick to the plywood due

to this smooth laminate film surface. The smooth film surface gives a smooth

finish to the resulting concrete compared to other methods, and it does not

require additional plastering of such concrete because it is already very

smooth.

It should be noted here

that not all concrete shutter plywood is film-faced. They also come in other

types of plain or oiled. The ones with the phenolic image face are the sales.

Dimensionally

stable: Since it is used in the manufacture of shutters used

for casting concrete, its dimensions must be constant even under the extreme

heat conditions that develop during concrete curing.

Expensive: Phenolic

plywood is as expensive material as marine grade plywood because it is made

to meet high-quality standards compared to furniture-grade plywood.

Phenolic plywood is durable

and best serves its purpose when the sheets are well maintained. Avoiding

scratches, wear and tear, cleaning the surface, and applying mould-oil (parting

oil) (fritting oil) to the surface all contribute to its repeated use to

enhance its quality and make it more durable.

Even after the concrete has been

used repeatedly for casting, it can still be used to make good quality utility

furniture such as work-benches, table-tops and outdoor woodwork. For other

applications like this, buying used phenolic plywood can be much less expensive

because the same type can be purchased at a significantly lower price than

buying brand new plywood.

FAQ

What is the difference between phenolic

board and plywood?

The phenolic surface offers

many properties not found in other types of plywood products. In different

types of plywood, phenolic provides a rough and very stable surface. The

phenolic surface resists cracks and splits well from fasteners so it can be used in concrete formwork.

What is phenolic plywood used for?

Even after the concrete has been

used repeatedly for casting, it can still be used to make good quality utility

furniture such as work-benches, table-tops and outdoor woodwork.

Can phenolic boards get wet?

Although it is suitable for

concrete forms, it is not suitable for use in the construction of furniture or

store equipment. The edges of this board are painted with oil-based paint,

which is somewhat waterproof.

What is 'Phenolic bonded plywood'?

Phenolic bonded plywood

would simply mean plywood that has been made using synthetic phenolic

resins

How many times can you use the phenolic

board?

For casting concrete we can

use around 30 to 50 times but it depends on how you maintain

Also

Read: Classification Of Softwood And

Hardwood Is As Commercial Importance.

Also

Read: What Is Moisture Resistant

(Mr) Grade Plywood

Also

Read: What Is Boiling Water

Resistant (Bwr) Grade Plywood

Also

Read: What Is Marine Plywood Or

Boiling Water Proof Grade Plywood

great post . thankyou you for sharing useful information. we are also provider of shuttering plywood

ReplyDelete