In this article, we explained lap length, bend length and development length and hook length calculation

LAP LENGTH

How to Calculate Lap length?

The lap length is the overlap of the two rods, which

provides the required design length. In the RCC configuration, lapping is done

if the length of a bar is not sufficient to create the design length.

Lap length is the length provided to connect two rebars

to each other to securely transfer loads from one bar to another and instead

provide mechanical couplers

Suppose we want to build a building 15 m high. But 15m

single bar is not available in the market. The maximum length of steel

available in the market is usually 12m – 40feet, so you need to connect two

bars of 12m to get a 15m bar.

Each over-lap length = 50d (Practically)

Therefore, d = dia of bar

(over-lap length means Joining to the steel bar with extra

length of Steel bar)

Extra

Length = Over-Lap Length = Lapping Length

Theoretical Standards for Over-lap length:-

1. For Compressive member (vertical member) Standard

over-lap length = 40d (Vertical over-lap)

2. For Tensile member (Horizontal member)

Standard over-lap length = 50d (Horizontal

over-lap)

Problem-1: Find the length of steel bars including the over-lap length from the given beam below figure

Given

data:

Beam = Horizontal Member = 50d

Over-lap length Length of steel bar = 50d

We will use 12mm, 16mm and 20mm dia bars for the

calculation

Length = 6m

Solution:

Length of steel bar = Total length + over-lap length Length of steel bar = L + 50D

1. Length

of bar, if dia of bar = 12mm

12mm = 0.012m (12/1000 = 0.012)

= L + 50D = 6.0m + 50 x 0.012m = 6.60m

2. Length

of bar, if dia of bar = 16mm

16mm = 0.016m (16/1000 = 0.016)

= L + 50D = 6.0m + 50 x 0.016m = 6.80m

3. Length

of bar, if dia of bar = 20mm

20mm = 0.020m (20/1000 = 0.020)

= L + 50D = 6.0m + 50 x 0.020m = 7.00m

Must read: What is Lapping Zones for Column and Beam | lapping Zones

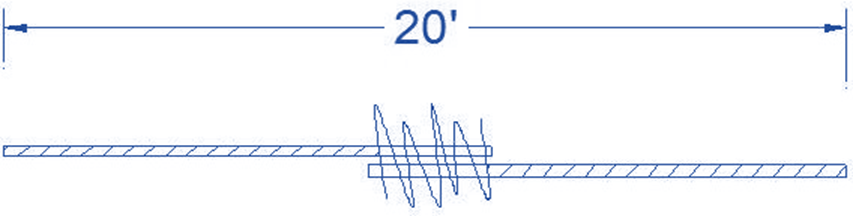

Problem-2: Find the length of steel bars including the over-lap length from the given Column below figure

Given

data:

Column = Vertical Member = 40d

Over-lap length Length of steel bar = 40d

We will use 12mm, 16mm and 20mm dia bars for the

calculation

Length = 20’

Solution:

Length of steel bar = Total length + over-lap length Length of steel bar = L + 40D

1. Length

of bar, if dia of bar = 12mm

12mm = 0.0393 feet

L + 40D = 20' + 40 x 0.0393' = 21.57200 feet (21 feet

655⁄64 inches)

2. Length

of bar, if dia of bar = 16mm

16mm = 0.0524 feet

= L + 40D = 20' + 50 x 0.0524' = 22.62 feet (22 feet

77⁄16 inches)

3. Length

of bar, if dia of bar = 20mm

16mm = 0.0656 feet

= L + 40D = 20' + 40 x 0.0656' = 22.62400 feet (22 feet

731⁄64 inches)

BEND LENGTH AND

DEVELOPMENT LENGTH

How to Calculate Bend Length and development of Bar?

When we bend the steel bar,

the length of the bar increases slightly as it is stretched in the bending area

(see image below). The length expansion depends on the quality of the steel and

the size of the bend.

The length of bar increases

when the increasing degree of bending increases and it decreases with higher

quality steel. (Fe250, Fe450, Fe500)

For 45° bend = 1d

For 90° bend = 2d

For 135° Bend = 3d

For 180° bend = 4

Bend

Length calculation:

Each Bend length = 16d (Practically) (development

length)

Therefore d = Dia of bar

Problem -1:

Find the length of steel bars including Bend length from

given the figure

Given

data:

Bend length = 16d

Length = 3m

We will use 12mm, 16mm and 20mm dia bars for the

calculation

Solution:

Length of steel bar = Total length + Bend length Length of steel bar = L + 16D

1. Length

of bar, if dia of bar = 12mm

12mm = 0.012m (12/1000 = 0.012)

= L + 50D = 3.0m + 16 x 0.012m = 3.192m

2. Length

of bar, if dia of bar = 16mm

16mm = 0.016m (16/1000 = 0.016)

= L + 50D = 3.0m + 16 x 0.016m = 3.256m

3. Length

of bar, if dia of bar = 20mm

20mm = 0.020m (20/1000 = 0.020)

= L + 50D = 3.0m + 16 x 0.020m = 3.32m

Problem -2:

Find the length of steel bars including Bend length from given the figure

Given

data:

Bend length = 16d

Length = 9’

We will use 12mm, 16mm and 20mm dia bars for the

calculation

Solution:

Length of steel bar = Total length + Bend length Length of steel bar = L + 16D

1. Length

of bar, if dia of bar = 12mm

12mm = 0.012m (12/1000 = 0.012)

= L + 16D = 9’ + 16 x 0.0393' = 9.6288 Ft

2. Length

of bar, if dia of bar = 16mm

16mm = 0.016m (16/1000 = 0.016)

= L + 16D = 9' + 16 x 0.0524' = 9.8384 feet (9 feet

101⁄16 inches)

3. Length

of bar, if dia of bar = 20mm

20mm = 0.020m (20/1000 = 0.020)

= L + 16D = 8.416' + 16 x 0.0656' = 9.4656 feet (9 feet

519⁄32 inches)

Lapping zone

Hook Length

How to calculate hook length for stirrups

What is Hook Length?

The hook is the extra length left at the rod joining corner of a stirrup so that the stirrup retains its shape.

Each Hook length

= 9D

Therefore, d = dia of bar

d = Diameter of stirrup

Total length of steel bar including Hook lengths = L +

9D + 9D = L+18D

Problem-1:

Find the length of Stirrup from the given figure if dia of

Stirrup = 6mm and 8mm

Given

data:

Length - 0.30m

Breadth – 0.40m

Length of Stirrup or tie = L + 18D

Solution: Ø = 6mm & 8mm for Stirrup or Tie

(i). Length of Stirrup or tie = L + 18D

Therefore, 'L' = ( L + B ) x 2

= (0.30+0.40) x 2 = 1.40m

Length of Stirrup or tie = 1.40 + 18 x 0 .006 = 1.508m

(ii).

Length of Stirrup or tie = L + 18D

Therefore, 'L' = ( L + B ) x 2

= (0.30+0.40) x 2 = 1.40m

Length of Stirrup or tie = 1.40 + 18 x 0 .008 = 1.544m

Must

read: How

To Calculate Cutting Length For Square Stirrups

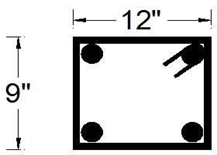

Problem-2:

Find the length of Stirrup from the given figure if dia of

Stirrup = 6mm and 8mm

Given

data:

Length – 9”

Breadth – 12”

6mm = 0.236”

8mm = 0.314”

Total length (L) = Therefore 'L' = (L + B) x 2 =

(9" + 12") x 2 = 42"

Length

of Stirrup or tie = L + 18D

Solution: Ø = 6mm & 8mm for Stirrup or Tie

Length

of Stirrup or tie = L + 18D

Therefore, 'L' = (L + B) x 2

= 42"+18 x 0.236"

= 46.248"

= 46.248/12 = 3.854 Ft

Length

of Stirrup or tie = L + 18D

Therefore, 'L' = (L + B) x 2

= 42"+18 x 0.314” = 47.652”

= 47.652/12 = 3.971 Ft

Must

read: How

To Calculate The Quantity Of Steel In Column

Must

read: Minimum

Size of Concrete Slab, Beam & Column

FAQ

Why hook is provided in stirrups?

1. Hook

is provided in stirrups for the following reasons:

2. To avoid buckling of the column.

3. The

main requirement for protection against bond failure is that the steel provides a good extension of the bar length beyond where it is required to create

its yield stress, and this length must be at least equal to its growth length.

However, if the actual available length is not sufficient for total growth,

special anchors such as cogs or hooks or mechanical end plates should be

provided.

4. It resist

seismic movement.

5. To

prevent the concrete from cracking externally.

6. it

prevents the steel from slipping from the concrete.

7. Hold

the steel tight by positioning the long steel rods.

What is Lap Length?

The lap length is the overlap of the two rods, which

provides the required design length. In the RCC configuration, lapping is done

if the length of a bar is not sufficient to create the design length.

What Is Bend Length?

The bend deduction is the

difference between the bend allowance and twice the outside setback

The bend allowance is the

arc length of the bend as measured along the neutral axis of the material you

are using.

What Is the Lapping Length of Rebar?

1. For Compressive member (vertical

member) Standard over-lap length = 40d

(Vertical over-lap)

2. For Tensile member (Horizontal

member) Standard over-lap length = 50d

(Horizontal over-lap)

Must

read: Plain

Footing Quantity Survey | Volume Of Concrete | Area Of Shuttering | Area Of

Bitumen Paint

Must

read: Raft

footing Quantity Survey | Volume Of Concrete | Area Of Shuttering | Area Of

Bitumen Paint

Must

read: Step

footing Quantity Survey | Volume Of Concrete | Area Of Shuttering | Area Of

Bitumen Paint

No comments:

Post a Comment