HOW DO YOU INSTALL ELECTRICAL CONDUIT ON CONCRETE SLAB?

The following points are the sequence of operations for the safe installation of PVC / GI pipes and components in concrete slabs according to standard procedure and code.

Points To Follow On

Material Ordering and Shifting

1. Check the approved

drawings, and order the correct size and type of pipe and its components for

the installation

2. Ensure that the conduit

and its components received for installation are free from rust and transport damages.

3. Remove the packing of

PVC conduits. Make sure packing materials like paper and polythene Cover are not

shifted to the concrete roof slab

4. The PVC conduit and its

components are carefully shifted to the roof slab using a lift or labour for the installation.

Marking Electrical Point

/ Wall Conduit Drop on Slab:

Ensure Slab Shuttering and

bar bending (Steel) Work is completed and the roof is ready for Electrical Work.

Step

1:

After completing the steelwork, Mark the wall location for below the slab using the Architecture floor plan. It will be easy to locate the drops for Wall Light

Points, switch and any other drops required for the electrical system (Refer to Electrical Pipe routing Plan).

Step

2:

Mark the opening size in Slab or Beam as per the approved electrical drawing to avoid

wall conduit passing through the window, door and shaft openings

Step

3:

Mark the electrical points on the slab and Wall Conduct Drop-in Beam according

to the approved electrical routing layout

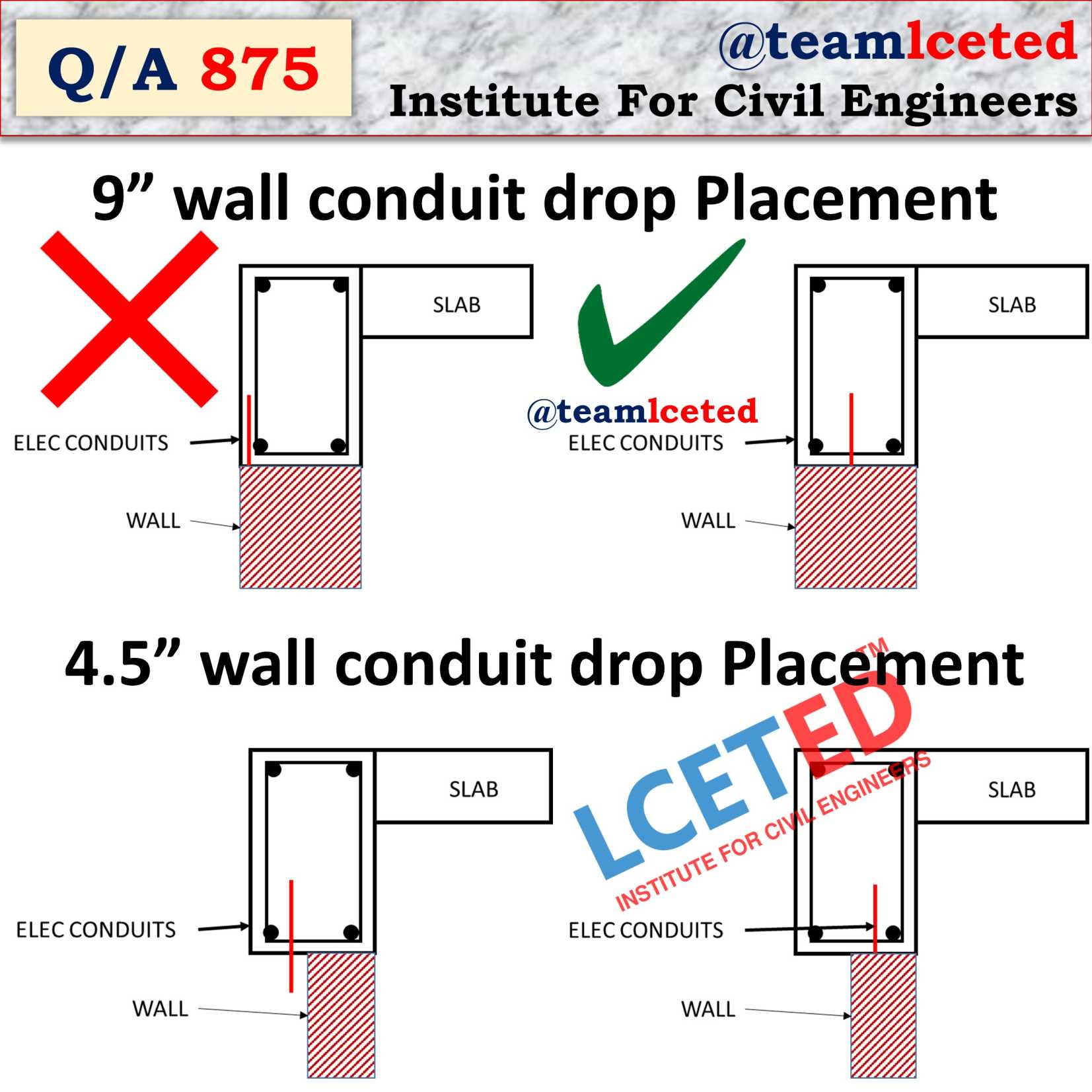

Note:

1. Ensure marking of Wall

conduit drop is placed in the centre of wall.

2. Ensure wall thickness,

whether it's 9” or 4.5” wall. If it's 9” wall place the conduit in the centre of the

wall, if it's 4.5” wall Place the conduit knowing which side of the beam wall is constructed.

For study:

3. Use Chalk for making the location of electrical points on slab and wall drop and PVC conduit routing

should be marked by using chalk

Installation of Conduit and Junction Box

in slab:

Points

to remember while Installing of Conduit and Junction Box

in slab

1. Make sure the right size of conduit is used per the approved Electrical

Pipe routing Plan.

2. Before the concrete is poured, the ceiling Conduits

must be laid in the prepared shutter works of the ceiling slab. - Pipes, junction

boxes, components, joints, etc. should be placed along the pipes.

3. Use a deep junction box for fan, spotlight, surface

mounted lighting fixtures and cable pulling.

4. Use long radius bend or PVC Conduit bending spring used

as per site requirement for the wall drop.

5. Suitable adhesive used for Joints between PVC

conduits and fittings. PVC conduit sanded before glueing for better insertion on

the fitting

6. Ensure some distance

between the conduits and Try to avoid the overlapping of conduits.

7. Ensure at least 1” - 25mm spacing gap between PVC

conduits running in parallel. So, that Placed PVC conduit is fully covered by

concrete and will avoid honeycomb or structural defects in the future.

8. In-wall drops where vertical conduits are used should be Concealed

and brought out of beams, All such ends should be protected on the bottom of beams

using paper for future extension (extension done by couplers)

9. Light / Fan points should be marked using paint

(yellow or red) for identification on slab shuttering

Slab Concrete

Points

to remember on slab concrete

1. The conduits should to

checked before concrete for any movement or damages. The electrical team should be

present during the pouring of concrete to take care of the conduit and to avoid

any damage by others or dislocation of joints.

2. PVC conduits placement

For the double reinforcement slab,

PVC conduits shall be placed at the bottom of the Top layer rebar

For a single reinforcement slab,

PVC Conduit should be placed at top of rebar with

binding Steel Wire.

3. Check PVC conduits are

tied with reinforcement using binding wire. The PVC conduit should be tightened in with short intervals not exceeding 1 m and Extra binding wire near each PVC

conduit coupler, PVC Bend and junction box

4. The open ends of the conduit should be closed when

concreting with caps or plugs to avoid blockages of the entry

Note:

use thermo-charcoal sheets to close junction box, fan box and wall drops. We can also use paper and clay. Ensure that

routes are not closed until works are inspected and approved.

5. Consultant/client/contractor approval should be

obtained for PVC conduit installation before concrete pouring.

6. At last we need to take photos and video of the pipe

routing for documentation

MUST READ: HOW

DO YOU INSTALL ELECTRICAL CONDUIT IN BRICKS / BLOCK MASONRY?

LCETED INSTITUTE FOR CIVIL ENGINEERS

No comments:

Post a Comment