Plywood vs Blockboard

Plywood and blockboard are two separate and distinct

things. In this article, we will look at the differences between these two types

of engineered woods

The

main differences between the two are listed below.

Variation In Composition and

How They are Made.

Plywood sheets commonly used in the manufacture of wooden

furniture are made from several thin sheets of individual veneers - wood

(layers/pieces of wood). All these layers are pressed together to form a

plywood sheet. If all of these individual layers of wood are derived from one

hardwood, the plywood sheet usually obtained is called 100% hardwood plywood.

Also Read: All You Want To Know About Plywood To Use On Interior Work

The core of the blockboard, on the other hand, is made of solid wood

blocks (these blocks are rectangular blocks/strips built from softwood).

All of these small blocks are approximately the same size and are set from end

to end to form the entire Blockboard core. Like plywood, an upper and lower

veneer (wooden layer) is bonded/glued to these blocks to create faces/surfaces.

Externally the plywood and

blockboard are both identical (especially if you do not see the edges of the

board), although the pictures above prove that the composition of the blockboards

is completely different.

The difference in The Way They are

Used.

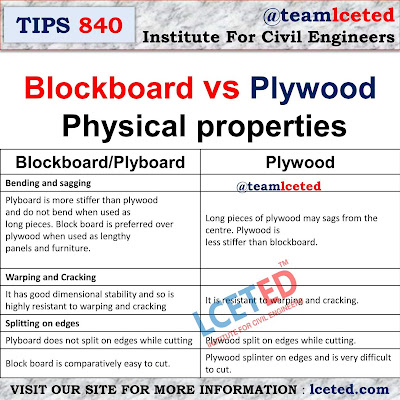

Although plywood is

suitable for most furniture-making needs, it tends to sag or bend when very

long pieces are used. In such cases, it is preferable to use blockboards rather

than plywood.

For example, when long

pieces of wood are needed for furniture such as long tables or countertops and

some load-bearing benches, blockboards are preferred over plywood. Other common

uses of Blockboard such as doors, panels and partitions.

The difference in Material Used.

Best quality commercial and

marine plywood are made using veneers that are thicker and heavier than softwood. Hardwood is considered to be a stronger and more durable material than

softwood. An example of hardwood is

something like teak wood

Blockboards are usually

sandwiched between hardwood veneers with a centre made of softwood blocks

(e.g. a mango tree). Sometimes two veneers are used on either side to reinforce

the blockboard.

The softwood core makes the

board lighter in weight, however, the use of solid wood blocks ensures that it

is strong enough to withstand significant loads.

Also Read: Solid Teak Wood Vs Plywood | Pros And Cons | Homeslibro

Differences in workmanship

Unlike plywood, which is

uniform throughout its length and width, blocks of blackboards may have small

gaps between them that cannot be seen from the outside. Due to this the nails driven

to the boards (for example to attach a frame to the board) can sometimes go

into these gaps instead of solid wood. However, this is usually not a major

drawback.

Ease of handling

Strength and durability

Water and moisture resistant properties

Physical properties

Sizes Available

Conclusion

Plywood and blockboard will be selected depending on the application. Blockboards are preferred over plywood for elongated elements such as furniture, shelves, desks, etc. Plywood is recommended for kitchen cabinets and interior work, where the gaps should be less and carry more loads. Blockboard is preferred for partitions, doors, etc.

Also

Read: How Choosing The Right Kind Of

Plywood Can Save You Money? - Homeslibro

If you find

This information is helpful, please share it.

Thanks! For reading the article...

great post . thankyou you for sharing useful information. we are also provider of block board plywood

ReplyDelete