It's generally, used as a finishing layer or protective layer for

plywood, MDF, particleboard, wooden furniture, wall panels and flooring its

made up of a composition of artificial material, they are made of joining thin

layers of flat paper and plastic resins.

The laminate is printed with a

decorative pattern or colour.

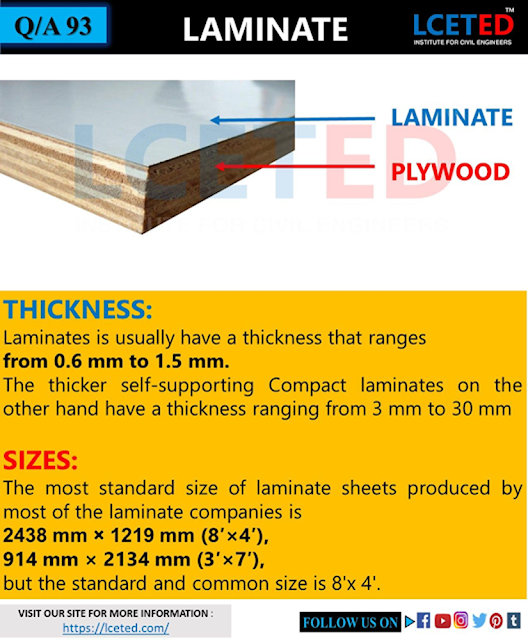

What are the Standard Sizes of

Laminate?

What is the Standard Thickness of

Laminate?

What is the manufacturing process of

laminate?

Impregnating the paper: the process

begins by soaking strips of paper in resin. Decorative plastic laminate can be

made in different grades or thicknesses depending on its intended use. There

may be from 7 to 18 layers of paper combined into the final sheet. The bottom

layer is of Kraft paper, the top layer of sheet is translucent middle layer is

the decorative layer.

Drying-resin is impregnated sheets are

then put into the drying chamber and next they are cut into stacked layers. The

clear layer and the decorative layer are on the top of the Kraft paper.

Finishing- dry sheet is cut into the desired size.

TYPES OF LAMINATES BASED ON

MANUFACTURING PROCESS

Low-pressure laminate: Low-pressure

laminates are decorative paper on which melamine polish is applied. Which I

fixed on M.D.E (Medium Density Fibreboard).

High-pressure laminate: High-pressure

laminates are decorative sheets that are fixed on plywood.

Also Read: What Is Laminated Plywood? | Prelamianted Plywood | Lamination - Homeslibro

TYPES OF LAMINATES BASED ON SURFACE

FINISH

1.

Matte finish laminate

2.

Glossy finish laminates

3.

Textured finish laminates

4.

Solid colour laminate

5.

Digital laminates

1. Matte Finish Laminate

Matte finish decorative laminate has a

surface that looks aesthetic and it gives a perfect look when it is being

used for different furniture requirements.

It resists heat and scratch.

2. Glossy finish laminates

Glossy finish laminate area covered

with plastic membrane sheets, acrylic sheet, painted glass, Duco paint, glazed

tiles and paints to achieve the desired high gloss finish.

3. Texture Finished Laminate

In this type of laminate when you touch

it you can feel the texture of laminate.

These laminate create an impressive

impact on the furniture.

4. Solid Colour Laminate

These types of laminates have single

solid colour without any prints or texture on it.

They are mainly used in kitchen countertops and bathroom areas.

5. Digital finished laminates

Digital laminates are customised printed laminates for interiors, which offers architects and designers an easy, simple, and reliable mode of artistic expression.

Uses

Decorate laminates are used for the

interior work of houses.it gives an attractive look for house interiors, walls.

It is also used in industrial areas

which have high resistance to scratch.

It is also used in offices, hotel

furniture.

Advantages

· cleaning process is

easy

· Economical

· Available in a wide

variety of designs, shapes, textures & colours.

· High resistance to

scratch and it is also moisture resistant.

· It has a good

waterproof.

Disadvantages

· It is artificially

made

· It is not durable.

Also Read: Woodworking Materials Guide for Beginners! | Woodworking Handbook

lceted is a great blog site. I do always follow and choose your post. I bought a floor mop from a suggested website and read a floor mop review website. Please, you can check & suggest to me if can I follow this website to purses some products?

ReplyDeleteThank you for sharing about content on laminate sheets, but if you any looking for alternative laminate sheets then advancelam is the right place for you. visit - https://www.advancelam.in/

ReplyDeleteThanks for sharing excellent information.

ReplyDeleteThanks for educating us!

ReplyDeleteJoana | drywall installation baltimore

I discovered your blog site website on google and appearance some of your early posts. Preserve up the great operate. I just extra increase Feed to my MSN News Reader. Looking for toward reading far more by you later on!… captive shot blasting

ReplyDelete