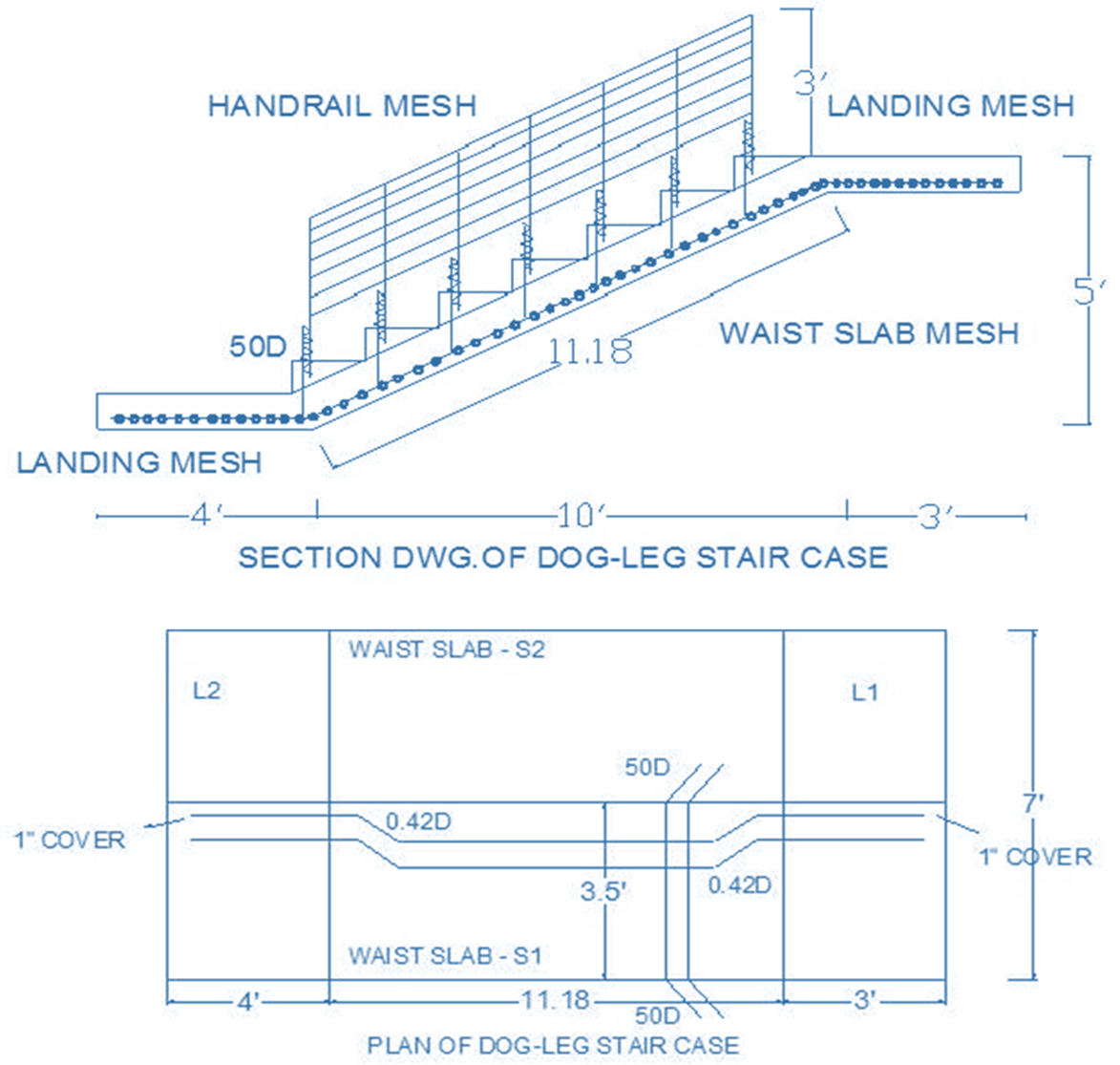

In this article, we explained how to calculate the Bill of Quantities And Bar bending schedule for Staircase (Step by Step procedure of Doglegged Staircase) For a given plan & Section Plan of Doglegged Staircase.

To Find

(i). Weight of Steel required for

a. Main bars,

b. Distribution bars,

c. Extra bars and

d. Hand Rail mesh.

The thickness of Waist Slab and

Landing = 6"

(ii). No. of Steel bars required, of length 40Ft/12m

(iii). Bill of Quantities for Staircase Reinforcement

if Rate of steel /kg = 65 rupees (Jan 2022).

GIVEN DATA

COMPONENTS OF STAIRCASE

Reinforcement Details:

(a). Waist Slab mesh = Ø 10mm@100mm or 4"

(b). Landing mesh = Ø 10mm@100mm or 4"

(c). Extra bar = Ø 8mm@ 100mm or 4"

(d). Handrail mesh = Ø 8mm@ 100mm or 4"

(I). Waist Slab (Slab 1 & Slab 2):

Note:

(a). While providing steel mesh in waist slab, 1"

concrete cover shall be deducted from each side of waist slab's Main Bars and

add the over-lap length of 50d on each side of Distribution Bars to join the hand-rail

mesh

(b). Each Crank Length = 0.42D

Where, D = Depth of Slab -Top and Bottom concrete cover

D = 6" - 1" - 1" = 4" or 0.333 Ft

(c). the formula used to find,

Number

of Main Bars = (Length of Longer Side / Spacing) + 1

Number

of Distribution Bars = (Length of Shorter Side / Spacing) + 1

Given

Dia of main bar = 10mm - 0.0328 Ft

1.

Length of Distribution Bars = 4' + 11.18' + 3' + 0.42D x 2 -

1" - 1"

= 4' + 11.18' + 3' + 0.42 x 0.333 x 2 - 0.1666

=

18.293 Ft

2. Length

of Main Bars = 3.5' + 50D x 2

= 3.5' + 50 x 0.0328 x 2

=

6.78' Ft

3. Number of Distribution Bars = (Length

of Shorter Side / Spacing) + 1

L = 3.5’ - 3'6"

L = 3'6"-1"-1" = 3'4"

Number of Distribution Bars = [3'4" / 4"] + 1

Number of Distribution Bars

= [3.333' / 0.333'] + 1

Number

of Distribution Bars = 11 bars

4. Number

of Main Bars = (Length of Longer Side / Spacing) + 1

L =11.18'-1"-1" = 11.01'

L = [ 11.01 / 4" ] + 1

Number

of Main Bars = [11.01 / 0.333] + 1

Number

of Main Bars = 34.06 approximately equal to 34 bars

5. Total

Length of Steel bars = (length of Distribution bar) x (no. of Distribution

bars) + (length of Main bar) x (No. of Main bars)

Total

Length of Steel bars = 18.293 x 11 + 6.78 x 34 = 431.743 Ft

6. Dia of the bar for Bottom and Top Slab mesh = 10 mm

According to thumb rule:

Slab mesh: Dia - Ø 10mm @ 150mm / 6"

Read About:

HOW TO CALCULATE WEIGHT OF STEEL BARS IN FEET

HOW TO CALCULATE WEIGHT OF STEEL BARS IN METER

8.

Total weight required for waist slab = weight in Feet x Total

length x no. of waist slab

= 0.188 x 431.743 x 2

Total

weight required for waist slab = 162.335 kgs

(II). Extra Bar

Extra bar = Ø 8mm @ 100mm / 4" - 8mm = 0.0262 Ft

Note:

Extra bar is provided at a distance of L / 4 from corner of Slab where L =

length of x-bar including crank length

Length

of each extra bar = [L / 4] + over-lap length = [ L / 4] + 50 D

1.

Length of each extra bar in Distribution Bar

L = 11.18 + 0.42D x 2

L = 11.18 + 0.42 x 0.333 x 2

L =

11.459 Ft

Length of each extra bar = [L / 4] + over-lap length = [

L / 4] + 50 D

Length

of each extra bar = [11.459

/ 4] + 50 x 0.0262 = 4.174 Ft

2. No.

of Extra bar in Distribution Bars = No. of Distribution Bars x 2 = 11 x 2 = 22

3. Total

length of Extra- bar = length of Extra-bar x no. of Extra-bars =

4.174 x 22 = 91.828 Ft

4. weight

of Extra bar = 8 mm ; Extra bar = Ø 8mm @ 100mm / 4"

According to thumb rule:

Read about:

HOW TO CALCULATE WEIGHT OF STEEL BARS IN FEET

HOW TO CALCULATE WEIGHT OF STEEL BARS IN METER

5. Total

weight required for Extra bar = weight of the bar x

Total length x no. of Waist Slabs

= 0.1204 x 91.828 x 2

=

22.112 kgs

(III). Landing

mesh (Landing 1 & Landing 2):

When

calculating the reinforcement for the landing, it is not necessary to find the

length of the distribution bar because it is already added to the with waist

slab distribution bar length.

So,

It is necessary to determine only the length of the main bar.

Width of landing -1 =

3'

Width of landing -2 =

4'

Total

= 3' + 4' = 7'

1.

length of Landing mesh of Main bar = 7' - 1" - 1"

= 7' - 0.1666'

length

of Landing mesh Main bar = 6.833' Feet

2.

No. of Landing mesh Main bar = Number of

Main Bars = (Length of Longer Side / Spacing) + 1 = [ 6.8333 /

4" ] + 1

= [6.8333 / 0.333 ] + 1

No.

of Landing mesh Main bar = 21.52 or approximately equal to 22 bars Total width

3.

Total Length of Landing mesh Main bar = length of main bar x Number of Main

Bars

= 6.883

x 22 = 153.626 Ft

4. Total

weight required for Main bar = weight / Ft x Total length

10mm weight = 0.188kg/ft

= 0.188 x 153.626

= 28.881

kgs

(IV). Hand Rail Mesh:

1.

Length of X-bar = 11.18' - 1" - 1"

= 11.18' - 0.1666'

=

11.013 Ft

2.

Length of Y-bar = 3' - 1" - 1"

= 3' - 0.1666'

=

2.833 Ft

3.

No. of x - bar

L = 3'-1"-1" = 2'10"

No. of x - bar =

[ 2'10" / 4"] + 1

No. of x - bar =

[2.8333 / 0.333'] + 1

No.

of x - bar = 9.508 bars or approximately equal to 10 bars

4.

No. of y - bar

L =11.18'-1"-1" = 11.01

No. of y - bar =

[11.01 / 4" ] + 1

No. of y - bar = [11.01 / 0.333] + 1

No.

of y - bar = 34.06

Approximately equal to 34 bars

5. Total

Length of Steel bar = length of x -bar x no. of x -bars + length of y -bar x

no. of y -bars

= 11.013 x 10 + 2.833 x 34 = 206.452 Ft

6. Dia

of the bar for Hand Rail mesh in both directions = 8 mm

According to the thumb rule:

Read about:

HOW TO CALCULATE WEIGHT OF STEEL BARS IN FEET

HOW TO CALCULATE WEIGHT OF STEEL BARS IN METER

Total

weight of steel required = weight / Ft x Total length x no. of

Handrails = 0.1204 x 206.452 x 4

Total

weight of steel required = 99.427 kgs

Total Weight Of Steel Required

|

|

DIAMETER |

WEIGHT |

|

1. S1&S2 |

10mm |

162.335 |

|

2.

landing 1&2 |

10mm |

57.763 |

|

|

Total |

220.098 |

|

3.

Extra bar |

8mm |

22.112 |

|

4.

Handrail |

8mm |

99.427 |

|

|

Total |

121.539 |

No. of Steel bars required of length

40Ft/12m:

(a). Ø=10mm Required wt. of steel = 220.098kgs

1. Standard

length of each steel bar = 40 Ft/12m

2. Dia

of steel bar = 10mm

3. Weight

of 10mm Steel bar in kgs/Feet = 0.1881 kgs/Feet

4. Weight

of each steel bar of length 40'/12m = 0.1881 x 40 = 7.524 kgs

5. No.

of Steel bars of length 40' required = wt of steel required / wt of each steel

bar

= 220.098 / 7.524

= 29.25 or approximately equal to 30 bars of Ø10mm required.

For 29.25 steel bars the required weight of steel =

220.098 kgs (required wt of steel) For 30 Steel bars the required wt of steel =

7.524 x 30 = 225.72 kgs (Actual wt

of steel)

(b). Ø = 8mm Required wt. of steel = 121.539kgs

1. Standard

length of each steel bar = 40 Ft/12m

2. Dia

of steel bar = 8mm

3. Weight

of 10mm Steel bar in kgs/Feet = 0.1204 kgs/Feet

4. Weight

of each steel bar of length 40'/12m = 0.1204 x 40 = 4.816 kgs

5. No.

of Steel bars of length 40' required = weight of steel required

/ weight of each steel bar = 121.539 / 4.816 = 25.23 or approximately equal to 26 bars of Ø8mm required.

For 25.23 steel bars the required weight of steel =

121.539 kgs (required wt of steel)

For 26 Steel bars the required wt of steel = 4.816 x 26

= 125.216 kgs (Actual wt of steel)

|

BILL OF QUANTITES

FOR STAIR-CASE REINFORCEMENT |

|||||||

|

S.no. |

Description Dia of bar |

Unit Kgs |

Rate/unit in Rupees |

Total Quantity |

Total Amount in Rupees |

Remark |

|

|

Actual weight of Steel required in kgs |

Required bars of 40' length |

||||||

|

1 |

Ø10mm |

Kgs |

48.00 |

225.720 |

30 |

10834.560 |

1 |

|

|

|

|

|

|

|

|

|

|

2 |

Ø8mm |

Kgs |

48.00 |

125.216 |

26 |

6010.368 |

2 |

|

|

|

|

|

|

Total |

16844.928 |

|

|

|

|

|

Add 10% wastage |

1684.493 |

|

||

|

|

|

|

Add 5%

Contingencies |

842.246 |

|

||

|

|

|

|

TOTAL |

19371.667 |

|

||

If you find

This information is helpful, please share it.

Thanks! For reading the article...

No comments:

Post a Comment