How To Pour Concrete In Hot Weather | Recommended Practices And Precautions | Concrete Under Extreme Environmental Conditions

Any operation of concreting done at an atmospheric temperature above 40 °C or where the temperature of concrete at the time of placement is expected to be beyond 40 °C may be categorized as hot weather concreting. Concrete is not recommended to be placed at a temperature above 40 °C without proper precautions as specified in IS: 7861 (Part-I)–1975. The climatic factors affecting concrete in hot weather are a high ambient temperature and reduced relative humidity, the effects of which may be more pronounced with the increase in wind velocity.

EFFECTS OF POURING CONCRETE IN HOT WEATHER

The effects of hot weather may be summarized as

follows.

1. Accelerated

setting A higher temperature results in more rapid hydration leading to

accelerated setting, thus reducing the handling time of concrete and also lowering

the strength of hardened concrete. The workability of concrete decreases and

hence the water demand increases with the increase in the temperature of

concrete. The addition of water without proper adjustments in mixed proportions

adversely affects the ultimate quality of concrete. It has been reported that

an approximately 25 mm decrease in a slump has resulted from an 11 °C increase in

concrete temperature.

2. Reduction

in strength Concrete produced and cured at an elevated temperature generally develops higher early

strength than normally produced concrete, but the eventual strengths are lower.

Regarding the influence of simultaneous reduction in the relative humidity, it

is seen that specimens moulded and cured in the air at 23 °C and 60 per cent

relative humidity, and at 38 °C and 25

per cent relative humidity attained strengths of only 73 and 62 per cent,

respectively, in comparison with the specimens which are moist- cured at 23 °C

for 28 days. High-temperature results in greater evaporation and hence necessitates an increase in mixing water, consequently reducing the strength.

3. Increased

tendency to cracking Rapid evaporation leads to plastic shrinkage cracking, and

subsequent cooling of hardened concrete introduces tensile stresses. The rate

of evaporation depends on the ambient temperature, relative humidity, wind

speed and concrete temperature.

4. Rapid

evaporation during curing As the hydration of cement can take place only in

water-filled capillaries, it is imperative that a loss of water by evaporation from the capillaries be

prevented. Furthermore, water lost internally by self-desiccation has to be

replaced by water from outside. A rapid initial hydration results in a poor

microstructure of gel which is probably more porous, resulting in a large proportion

of the pores remaining unfilled. This leads to lower strength.

5. Difficulty

in controlling the air content At higher temperatures, it is

more difficult to control the air content in air-entrained concrete. This adds

to the difficulty of controlling workability. For a given amount of air-entraining agent, hot concrete entrains less air than does concrete at normal

temperatures.

Following Table Shows The Effects Of Pouring Concrete In Hot Weather On Different Stages Of Concrete Production And Placement:

Stage | Effect |

Production | Higher water demand for given workability, controlling difficulty of entrained air content |

Transit | Increased rate of water loss due to evaporation, loss of work workability |

Placing, finishing and curing | Water loss due to evaporation, increase in work loss rate, increase in setting rate, increase in plastic shrinkage tendency, increase in the tendency to increase high peak temperature cracking during hydration and decrease in long lasting strength |

Long-term | Variable appearance, Decreased durability, Lower strength |

Recommended

Practices and Precautions

Temperature Control of Concrete Ingredients

The temperature of the concrete can be kept down by

controlling the temperature of the ingredients as shown in Fig. The aggregates

may be protected from direct sun rays by erecting temporary sheds or shelters

over the aggregate stockpiles. Water can also be

Fig. Temperature control of ingredients

for hot-weather concreting

sprinkled onto the aggregate before using them in concrete. The mixing of water has the greatest effect on lowering the temperature of concrete because the specific heat of water (1.0) is nearly five times that of common aggregate (0.22). Moreover, the temperature of the water is easier to control than that of other ingredients. Under certain circumstances, the temperature of the water can most economically be controlled by mechanical refrigeration or mixing with crushed ice. The precooling of aggregates can be achieved at the mixing stage by adding calculated quantities of broken ice pieces as a part of mixing water, provided the ice is completely melted by the time mixing is completed. The cooling of concrete can also be achieved by nitrogen gas.

Proportioning of Concrete Mix

The mix should be designed to have minimum cement content consistent with

other functional requirements. As far as possible, cement with lower heat of

hydration should be preferred to those having greater fineness and heat of

hydration. Use of water-reducing or set-retarding admixtures is beneficial.

Accelerators should not be used under these conditions.

Production and Delivery

The

temperature of aggregates, water and cement should be maintained at the lowest

practical levels so that the temperature of concrete is below 40°C at the time

of placement. The temperature of the concrete at the time of leaving the batching plant should be

measured with a suitable metal-clad thermometer. The period between mixing and

delivery should be kept to an absolute minimum by coordinating the delivery of

concrete with its rate of placement.

Placement and Curing of Concrete

The formwork, reinforcement and subgrade should be sprinkled with cool

water just before the placement of concrete. The area around the work should be

kept wet to the extent possible to cool the surrounding air and increase its

humidity. Speed of placement and finishing helps minimize problems in hot

weather concreting. Immediately after compaction, the concrete should be

protected to prevent the evaporation of moisture by means of wet (not dripping)

gunny bags, hessian, etc. After the concrete has attained a degree of hardening

sufficient to withstand surface damage, moist-curing should begin. Continuous

curing is important because the volume changes due to alternate wetting and

drying promote the development of surface cracking. On the hardened concrete,

the curing shall not be much cooler than the concrete because of the

possibilities of thermal stresses and resultant cracking. High-velocity winds

cause a higher rate of evaporation, and hence windbreakers should be provided as

far as possible. If possible, the concreting can be done during night shifts.

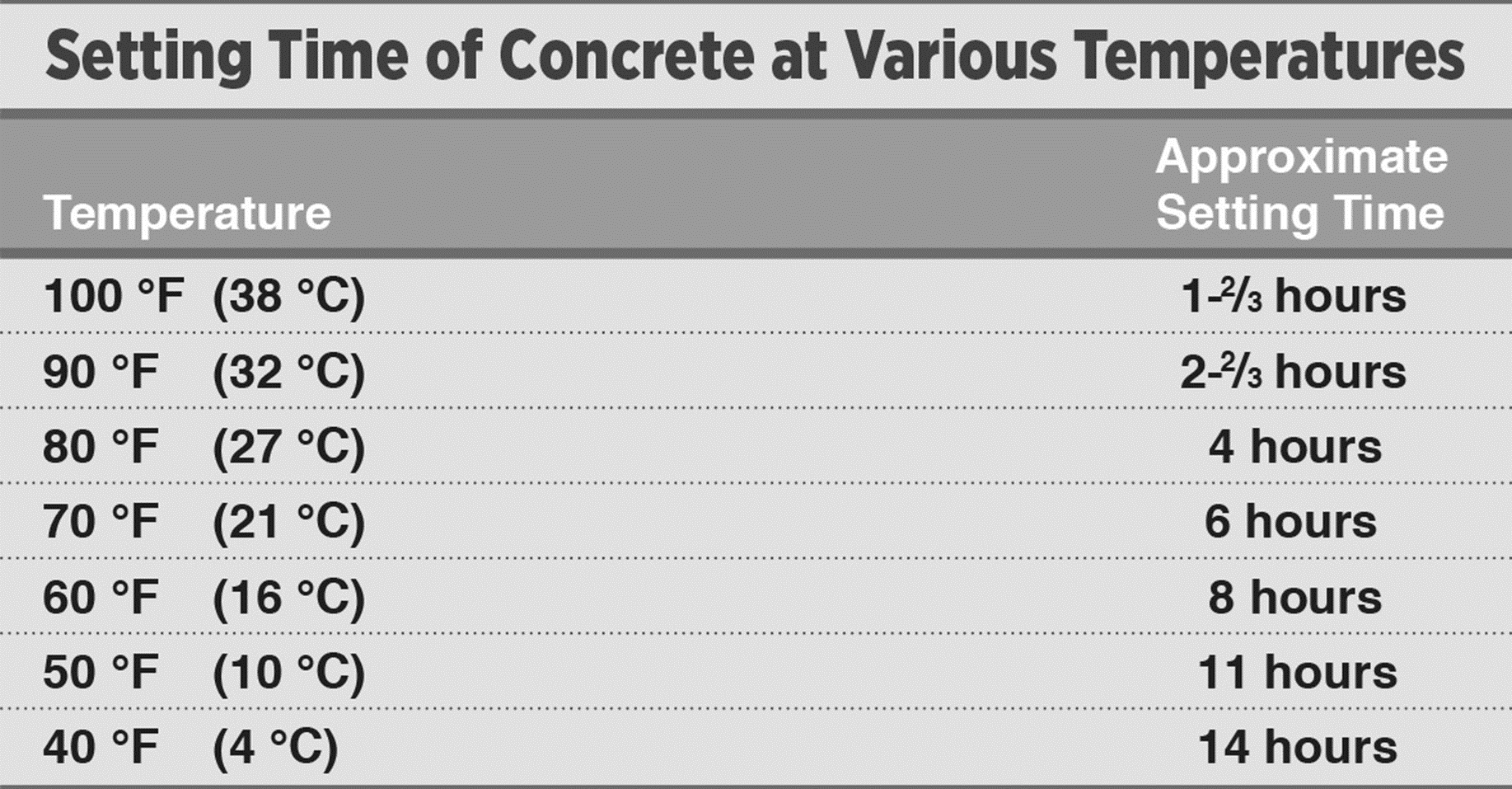

SETTING TIME OF CONCRETE AT VARIOUS TEMPERATURE

Tips for

Pouring Concrete in Hot Weather

If you find

This information is helpful, please share it.

Thanks! For reading the article...

No comments:

Post a Comment