AUTO LEVELLING

An automatic level, also

known as dumpy level or builder’s auto level, is a laser marking, optical

measuring device used to establish a horizontal plane. The instrument can be

used for small scale such as residential building construction to a big civil

engineering project. Due to its wide range of use, this instrument has become

very popular among professionals.

The term automatic level

can also refer to digital and laser levels that use different technologies to

ensure accurate levelling operation, which is very important in a

construction project. There are various types of auto levels available in the market, each one

designed for a specific job type. They are as follows:

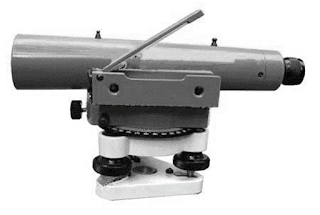

1. Dumpy Level

Dumpy levels, sometimes

called tilting levels, are older pieces of surveying technology that are still

in use, although they are being steadily replaced, as modern devices probe its

reliability. This level is used in general survey work such as setting property lines, laying out highways, power

lines, etc.

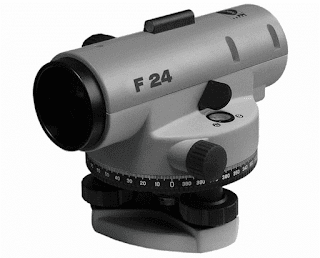

2. Builder’s Auto Level

When the level is set on

the tripod, levelled approximately, a swinging prism inside the level adjusts

to compensate for imperfections in the tripod levelling. This level can be set up quickly and is easy to

operate for most professionals. This instrument is suitable for making

horizontal markers for memory work, like the laying of bricks and blocks. It is

useful in setting foundations and flooring in residential buildings.

3. Laser Level

This level is also mounted

on a tripod at work sites. After levelling the tripod along with the laser

level mounted on it, the laser marker is spun to a horizontal angle

illuminating a horizontal plane. The beam is picked up by a sensor, attached to

a graduated staff, making an audible beep sound indicating that a level

horizontal plane has been achieved. This is useful for setting out masonry work

and laying of foundation work of a building.

4. Digital Level

This is the form of auto-level that uses an electronic eye to read digital bar-code data on the

graduated staff. The beauty of this instrument is its ability to record the data being measured along

with correlating information on curvature and refraction values, which gives a better

quality job. This is useful in road projects.

5. Laser-Line Level

This is the most common

level used by the general public. They are compact and easy to use. A

horizontal or vertical laser line is displayed across the surface, the level

set on, providing a level line to fix up interior details of a house. This has

been used in electrical, plumbing works in domestic and commercial buildings.

A. Typical Parts of an Auto

Level

The auto level has the

following components in three different views:

1. Right-side View

The levelling head is a very

important component in this view. It has three parts:

(a) A

circular plate, or tribrach, which carries a spirit level and the

instrument

(b) Three

levelling screws or foot screws

(c) A

footplate or trivet attached to the tripod head

The horizontal circle, just

above the tribrach, allows the instrument to rotate for

measuring horizontal angles.

2. Top View

This view shows the

following parts:

(a) Spherical

level, practically a spirit level where the bubble must be within the circle to

give a horizontal line of sight.

(b) The

instrument can be rotated by hand using ‘gun sight’ at the telescope.

(c) The

object focusing screw to focus the staff or other object image properly.

(d) Tangent

screws on each side help in finer adjustment for focussing the image of the

object.

3. Left-Side View

A mirror fitted over the

spherical level is the only new component in this view.

B. Principle of Autolevel Operation

The auto level has a

compensator mechanism that uses a combination of fixed prisms or mirrors and a moving prism,

suspended on a pendulum to give a

horizontal reference. By setting up the compensator correctly, it will ensure

that the ray of light through the centre of the reticule is exactly horizontal.

A damping mechanism is also

introduced within the pendulum system to prevent unwanted swinging during

movement of the auto level.

The reticule is a glass

plate with fine cross-hair embedded to provide height reference. The eyepiece should be

adjusted to give a clear focus of the image. The internal focusing lens is

controlled by the focussing screw, situated at the side of the telescope, to

bring the object image clear.

Fig. Components of Auto Level

C. Advantages and

Disadvantages of Auto Levels

The levelling operation can

be possible more accurately by using an auto-level. This level can be used in small-scale residential building

projects to large civil engineering projects. The wide range of use of this instrument

is advantageous for professionals. The telescope of this instrument needs

only be approximately levelled over the

tripod stand and then the compensating device, usually based on the pendulum system

inside the telescope, corrected for the residential establishments. So, the

levelling operation is made very simple over the other kinds of levelling instruments. The horizontal

line of sight is very much ensured by incorporating an additional fixed and

pendulum-type prism with the traditional focusing lens. This gives better

quality of reading in levelling operations.

In spite of its

user-friendliness for correct measurement opportunities, it suffers from an

instability problem. Due to its novel features inside, it is much more complex in construction. The cost

of construction is also high compared to other types of levelling instruments

available in the market.

If you find

This information is helpful, please share it.

Thanks! For reading the article...

Very nice information..

ReplyDelete