CONSTRUCTION SCHEDULING PROCEDURES

Various scheduling procedures are discussed below.

Construction Schedule

This schedule consists of the duration of construction of

various components of the work. Based on the availability of the following

data, the construction schedule can be made:

(i) Number of activities

(ii) Quantity of various items of works

(iii) Labour contribution and number of field workers

(iv) Machinery required

(v) Stages of activities to be executed

Labour Schedule

Under this schedule, one can know in advance the type of

labour and the numbers required from time to time. This is needed to recruit

the persons (both skilled and unskilled labour) needed so as to have a

continuous flow of work without any disruption.

Material Schedule

This is an important schedule by which one will be in a

position to know the requirement of various construction materials well ahead.

This helps to start the work and continue without any dearth of materials at

any stage. If adequate funds and storage facilities are available, materials that

can not be spoiled with time may be stored to some extent.

Equipment Schedule

The success of any project depends to a large extent on

the proper use of construction equipment. Properly maintained equipment and

application in construction can bring down construction time and cost. Further

proper deployment of equipment judiciously yields economical results without a heavy financial burden on the project. Thus project management should properly

plan the judicious deployment of equipment.

Expenditure Schedule

The project engineer and his team have to primarily

judge to give the most economical construction. Thus it is essential to review

the financial position of the project at regular intervals so as to ensure the

following:

(i)

The annual expenditure, if any, of the project has to be kept within the

allotment.

(ii)

A properly balanced expenditure will result in early completion of work.

CONSTRUCTION SCHEDULING TECHNIQUES

In any project, the sequence through which the project is

to develop should be decided. The requirement is met in a systematic manner by

scheduling techniques. The project scheduling techniques are concerned with resource time. One of the objectives of project management is to optimise

the use of resources. Scheduling techniques offer solutions to the optimisation of

project time.

Technical scheduling can be done by different methods

depending on the size of the project. The methods used are as follows:

1. Bar

charts

2. Milestone

charts

3. Network

analysis

Bar Charts

1. Principle

of Bar Chart

In dealing with complex

projects, a pictorial representation showing the various jobs to be done and

the time and money they involve are generally helpful. One such pictorial chart,

also known as the bar chart, was developed by Henry Gantt around 1900. Bar the chart is also referred to as the Gantt chart.

A bar chart consists of two

coordinate axes, viz., one representing the time elapsed and the other

representing the job or activities to be performed. The jobs are represented in

the form of bars as shown in Fig below

Bar chart

The beginning and end of each

bar represent the time of start and time of finish of that activity. The length

of the bar represents the time required for the completion of the job or

activity.

In any project, there may be

some activities which are to be taken up simultaneously but may take different

lengths of time for their completion (e.g., Activities A and C) and some

activities have to be taken up only after the completion of some other activity

(e.g., Activities A and B). There may also be some activities that are

independent of all other activities (e.g., Activities D and E).

2. Example

Let us consider the steps involved in the construction

of a factory shed. Major activities identified in the construction of a

factory shed where machines are to be erected are presented in the Table below. The

activities have been identified and arranged in a logical sequence. At the

factory site, no water is available and is not feasible to get water from the surrounding. Hence, a bore well has to be sunk before starting the actual

construction. Hence, excavation of the foundation and sinking of the bore well may be

started simultaneously. That is, at the end of one week, water will be

available.

Activities of construction of factory shed

|

Activity no. |

Activities |

Time required (weeks) |

|

1. |

Excavation

for foundation |

4 |

|

2. |

Sinking

of tube well |

1 |

|

3. |

Base

concrete and placing of column reinforcement |

2 |

|

4. |

Shuttering

and construction of columns |

4 |

|

5. |

Fabrication

of truss at site |

1 |

|

6. |

Erection

of trusses |

4 |

|

7. |

Construction

of entrance and all round walls |

4 |

|

8. |

Roofing |

2 |

|

9. |

Doors,

Windows and Shutters |

2 |

|

10. |

Plastering |

1 |

|

11. |

Construction

of machine blocks |

2 |

|

12. |

Electrification |

1 |

|

13. |

Flooring |

1 |

|

14. |

Painting |

2 |

Other activities succeed one after the other. These

activities are shown in a bar chart in Fig below, with the given data and given

precedence/succedent relationships.

As seen from the bar chart, the total time required for

completion of the factory shed project is about 30 weeks.

3. Limitations

of Bar Chart

Following are the limitations of a bar chart:

1. A bar chart can be successfully used only for small

projects.

2. Bar charts can not be updated when there are many

changes.

3. The progress of the project can not be assessed at

different stages scientifically.

4. Bar charts do not equate time with cost. That is

time-cost relationship can not be derived.

Bar chart for factory shed

5. Delay in the work can not be deducted.

6. It does not clearly show the interdependencies

between the various activities in the project.

7. It does not reflect the critical activities of the

project.

8. Bar charts do not provide methods for optimising the allocation of resources.

Milestone Charts

1. Principle

of Milestone Chart

The shortcomings or the inadequacies of the bar chart

have been modified to some extent in the milestone chart. In every activity, there

are certain key events that are to be carried out for the completion of the

activity. Such key events are called milestones and they are represented by a

square or circle. These events are those which can be easily identified over

the main bar representing the activity.

It has been observed in a long time activity the details

will be lacking. If the activity is broken into a number of sub-activities or

key events each one can be recognised during the progress of the project. In

such cases controlling can be done easily and some inter-relationships may be

established between the activities. In a milestone chart, the events are in

chronological, but in a logical sequence. The figures below show the conventional

bar chart and milestone chart.

Conventional bar chart

Milestone chart

2. Limitations

of Milestone Chart

Following are the limitations of a milestone chart:

(i) This method has one great deficiency, that is, it

does not clearly show the interde- pendencies between events.

(ii) Here the events are in chronological order but not

in a logical and sequential order.

Network Analysis

1. Principle

of Network Analysis

The network analysis techniques, developed between 1950s

and 1960s, have now come to be used as an effective management tool for

planning, scheduling and controlling of complex projects.

The term project network analysis is a general term

covers all the network techniques used for planning, scheduling and controlling

of projects. The three techniques commonly used are as follows:

(i) Critical Path Method (CPM)

(ii) Program Evaluation and Review Technique (PERT) and

(iii) Precedence Diagramming Method (PDM) or Precedence

Network Analysis (PNA).

These network techniques produce time-oriented diagrams

having activities organised into a logical order.

2. Network

Diagram

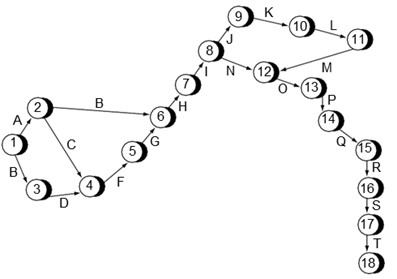

Network Diagram is a

graphical flow plan of the activities that are to be accomplished for

completing the project. The precedence and succedent relationships between

activities are identified first.

Sequencing activities

refers to finding out the logical relationships among the activities of a

project and arranging them accordingly. By studying the project features the

different activities involved in a project the concerned officer-in-change of

the project establishes the precedence-succedent relationships between the

activities.

While deciding the logical

relationships between the different activities, activities which are mandatory

to be operated before some of the activities to be taken up have to be identified. In addition, there may be certain activities that may not be mandatory

dependencies (such activities are called discretionary dependencies) are to be

identified. After finalising all the activities and finding their

characteristics the network diagram for the project can be drawn.

Activities of construction

of a building are given in Table below and shown as network diagram in Fig. below

Activities

of construction of a building

|

Activity |

Description |

Immediate

predecessors |

|

A |

Plan approval |

– |

|

B |

Site preparation |

– |

|

C |

Arranging foundation materials |

A |

|

D |

Excavation for foundation |

B |

|

E |

Carpentry work for Doors and Windows for

main supporting frames |

A |

|

F |

Laying foundation |

C, D |

|

G |

Raising wall from foundation to sill |

F |

|

H |

Raising wall from sill to lintel level |

E, G |

|

I |

Casting of lintels |

H |

|

J |

Raising wall above lintel up to roof base |

I |

|

K |

Electrical wiring |

I, J |

|

L |

Casting of roof |

J |

|

M |

Fixing frames of doors and windows |

L |

|

N |

Making of shutters |

J |

|

O |

Plumbing works |

L |

|

P |

Plastering |

O |

|

Q |

Making ready shutters to Doors and Windows |

P |

|

R |

White washing and painting |

Q |

|

S |

Fitting Electrical and plumbing parts |

R |

|

T |

Clearing the site before handing over |

S |

Network diagram for construction

activity

3. Definitions

of Network Techniques

(i) Critical Path Method

(CPM)

In a network the sequence

of activities arranged in each path will have a different duration. The path that

has the longest duration is called critical paths.

(ii) Program Evaluation and

Review Technique (PERT)

It uses three times, viz.,

optimistic time estimate, pessimistic time estimate and most likely time

estimate.

(iii) Precedence Network

Here each activity is

represented by a rectangular or square box. The time duration of the activity

is incorporated inside the modal box.

SOURCE: BUILDING CONSTRUCTION MATERIALS AND TECHNIQUES | P. PURUSHOTHAMA RAJ

If you find

This information is helpful, please share it.

Thanks! For reading the article....

No comments:

Post a Comment