DRAINAGE OF WASTE WATER AND SEWAGE

Wastewaters coming from the kitchen sink, washbasins and

urinals are not containing any solid matter. But sewage a solid material has to

be treated such that it also could be converted as wastewater.

NEED FOR TREATMENT OF SEWAGE

Nearly 75% of the water

supplied returns back in the form of wastewater. As there is a need for a water

supply system, there is an equal necessity to dispose of the wastewater. The

night- soil and urinary content of domestic sewage (originating from residential

areas) consists of potentially most dangerous organisms. Such organisms are

responsible for the occurrence and spread of water-borne diseases.

Sewage treatment is meant by the various steps undertaken in the process of transferring sewage into a harmless

liquid. That is to render sewage inoffensive without causing nuisance or odour

and to reduce or eliminate any possible contaminations of water supplies,

bathing areas, etc., by the untreated or un-disposed sewage.

SANITARY FITTINGS AND APPLIANCES

Sanitary fittings and appliances comprise traps,

water closets, flushing cisterns, etc., which are discussed below.

1. Traps

Traps are fittings that

are installed in drainage pipes to prevent the passage of foul air or gases

through drains, waste or soil pipes. This is possible because traps are

equipped with water seals having a minimum depth of 25 mm. Higher the depth

greater the effectiveness of the trap. Depth varies in practice from 25 to 75 mm

and 50 mm depth is quite common.

Qualities

of good traps are:

(i) They should have adequate water seal at all times

which is possible only when they are non-absorbent.

(ii) There should not be any projections that may

obstruct or retard the flow of water. Further, it should be smooth.

(iii) They should retain a minimum quantity of water

consistent with providing deep water seals with a large area.

(iv) Apart from self-cleansing, provision should be

therefore cleaning manually or otherwise.

Traps are classified based on shape as R-trap, Q-trap

and S-trap and based on use as floor trap, gully trap and intercepting trap.

The figure below of traps based on shape.

Traps

based on shapes (P-Q-S)

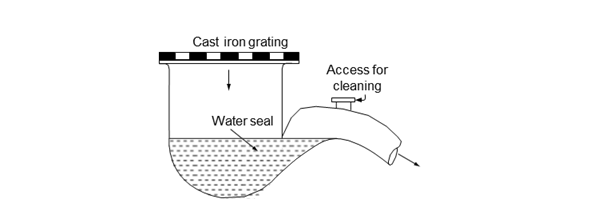

Floor traps are intended to

collect surface wash or wastewater from the floors of the bath and kitchen.

These are provided with cast iron grating at the top so as to retain coarse solid

matter. Thus preventing the matter to go along with wastewater and thereby

cause blockade - figure below

Floor trap

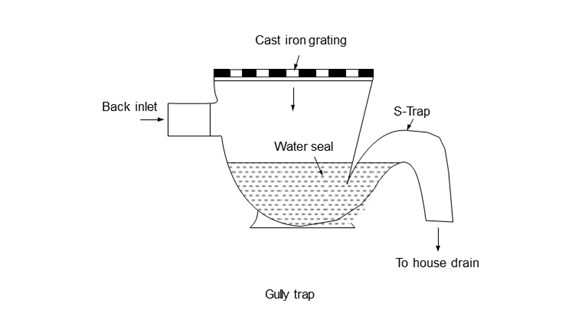

Gully

traps are intended to receive sullage water from baths, sinks and washbasins.

Further, they are also used to receive rain or surface water from house-tops or

back yards. The water seal is 50–75 mm. Waste pipes and rain-waste pipes are

invariably connected to drains through the gully trap (Fig. below).

Gully trap

Intercepting traps or also

called interceptors. These are installed at the junction of the house drain

and house sewer. The primary objective is to prevent the foul gases in the public

sewer from entering the house drainage system (Fig. below)

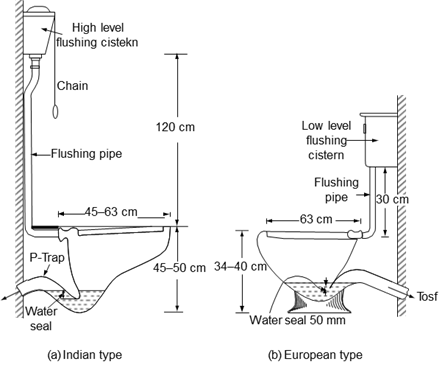

2. Water Closets

The water closet is a water-flushed-plumbing

figure designed to receive human excreta directly from the user. There are two

types of water closets, viz., Squatting or the Indian type and pedestal or the

European Type. Figures below (a) and (b) show the two different types.

Intercepting drain

Water closets

(i)

Indian Type

This has a squatting pan of

45–63 cm in overall length and 45–50 cm in height. The W.C. is connected to

soil pipe through a P-trap or S-trap.

(ii)

European Type

It is a wash down water

closet provided with a seat and cover and fitted with P-trap and S-trap. It has

a maximum overall height of 63 cm and a height of 34–40 cm.

Both the types of WCs are

provided through flushing cisterns and flushing pipes.

3. Flushing Cistern

This is a sanitary

appliance that is used by flushing out water closets, urinals, etc. There are two

types one is the valveless siphonic type and the other is valve-fitted siphonic

type. The former is preferred and largely used in practice.

4. Washbasins

The washbasin is also called as

lavatory basin. It is made of the white-glazed earthen wave, enamelled iron, etc.

There are two types, viz., flat back and angle back. Washbasins are fixed

either on brackets secured to the walls or on pedestals rising from the floor.

5. Sink

It is a rectangular shaped

receptacle used in the kitchen or laboratory for draining water. It is to be

located as far as possible near a window so as to get adequate light. The

height from the floor is about 90 cm to the top edge of the sink.

6. Urinals

There are two types, viz.,

bowl type and the slab or stall type. Both the types are flushed through a siphonic type of flushing cisterns. In the bowl type, the cistern may be hand-operated and of 5 l capacity. In the stall type, automatic flushing cisterns

are used.

PLUMBING SYSTEM OF DRAINAGE

A plumbing system of drainage

is one through which discharge from sanitary fixtures or appliances is

conveyed. The three principal systems are single stack system, the one-pipe

system and the two-pipe system.

1. Single Stack System

In this system, all waste

matters such as from bath, kitchen and sink and foul matter from urinals or

excreta from water closets are discharged into a single soil pipe. This pipe

also acts as a ventilating pipe. In this system complete reliance is built

entirely on the effectiveness of the water seal with the assurance that the entry

of gases from sewers are blocked. The advantages of the system are:

(i) Simplicity in design,

layout and easy plumbing of sanitary fixtures.

(ii) Better external

appearance of the building.

(iii) More compact system

and

(iv) More economical.

The main disadvantage with

this system is the easy breaking up of water seals in taps.

2. One-Pipe System

In this system, separate

vent pipes are provided. All the traps of water closets, basins, baths etc.,

are adequately ventilated to preserve the water seal. In this system, a caged

dome is provided projecting above the rooftop such that to allow a natural

outlet to the foul gas. This system requires a difficult arrangement of pipework and is also costlier than the single-stack system.

3. Two-Pipe System

In this system all soil

appliances such as water closets and urinals are connected to a vertical soil

pipe. All wastewater appliances such as baths, washbasins, sinks, etc., are

connected to a separate waste pipe which is disconnected from the drain by means

of a gully trap.

Thus in this system, there

are two sets of vertical pipes, viz., the soil pipe and the waste pipe, each

one is provided with a vent pipe. This system is the best plumbing system which

is most efficient in the conveyance of sanitary waste and also largely favoured

for adoption. However, this is the costliest of all systems.

LAYOUT OF BUILDING DRAINAGE

The following aspects have

to be considered in the design and construction of a drainage layout:

1. This layout should be

simple.

2. All pipes should be laid

in straight lines both in horizontal and vertical directions.

3. Abrupt changes in the direction of the pipeline may affect the natural flow.

4. In the points of the intersection of pipes and wherever bends occur, it is essential to provide

inspection chambers or manholes.

5. The contained angle

between the intersecting pipes should be less than 45° so as to ensure a

gradual and smooth flow.

6. Sewers should not be

ordinarily laid under a building. If it is inevitable a cast iron pipe should

be laid in straight reach with a uniform gradient.

PIPES FOR DRAINAGE

1.

Pipes and Gradients

Pipe sizes for house drains

and sewers are 100, 150 and 230 mm and in some cases 300 mm. In order to avoid

deposition of solid matter, the pipes should be laid as per the recommendation

of I.S. Code (IS: 1742–1972), Table below.

Recommended the gradient of sewer discharge pipes

|

Sl. No. |

Diameter (Pipe) |

Gradient |

Sewer Discharge |

|

(A) |

300

mm |

1 in

200 |

1.66m3mt |

|

(B) |

230

mm |

1 in

120 |

1.93m3mt |

|

(C) |

150

mm |

1 in

65 |

0.42m3mt |

|

(D) |

100

mm |

1 in

35 |

0.18m3mt |

Source: IS: 1742–1972.

2. Positioning of Pipes

The following points shall be kept in view while deciding the

positioning of pipes:

(i) All soil pipes, waste and ventilating pipes should be conveniently

grouped in shafts or ducts with adequate capacity. This provision is needed to

allow for inspection and repair work.

(ii) All the pipes needed for different purposes have to be adequately

provided for during the construction stage itself at their appropriate

positions.

(iii) When pipes are not embedded it should run clear of the wall with a

minimum clearance of 5 cm.

(iv) Waste pipes are to be separated from the house drains by using

gully traps. This arrangement is essential to prevent the entry of foul air or

gas, vermin, etc., into the building.

(v) The soil, waste and vent pipes should be vertically carried above

the top of the building. They are to be covered by copper, plastic or

galvanised iron wire domes. The arrangement is needed to prevent the nesting of

birds or inadvertent falling in of objects inside the pipe.

(vi) Diameter of pipes used for various purposes are given below

(Duggal, 1988)

|

(a)

Soil pipe |

100

mm |

|

(b)

Waste pipe – horizontal |

32–50

mm |

|

(c)

Waste type, vertical |

75

mm |

|

(d)

Vent pipe |

50

mm |

|

(e)

Anti-siphonage pipe: |

|

|

Connecting

soil pipe |

50

mm |

|

Connecting

waste pipe |

40

mm |

SLUDGE AND EFFLUENT

DISPOSAL

Sedimentation is carried out with the object

of removing such suspended minerals and organic matter from sewage. Sedimentation

tanks are units in which sedimentation is brought about. The lighter organic

sewage solids which settle in the sedimentation tanks are termed sludge. The

sewage that has been partially classified by the settling out of the solids is

known as the effluent.

In a general set up the disposal of sludge

can be done by adopting any one of the following methods:

(i) Dumping into waste bodies

(ii) Shallow Burial

(iii) Lagooning

(iv) Mechanical dewatering and

(v) Drying in Beds

If such a general disposal system is not available one has to go in for

a sedimentation tank. Generally, the sedimentation tank adopted is a septic tank

which is a horizontal continuous flow sedimentation tank. A description of the septic tank is explained in the next section. The putrescible and highly odorous

efficient from the septic tank requires to be properly treated and disposed of

sub-surface irrigation field method or discharging into other soil absorption

system such as soak pit and leading cell pool which is described later.

1. Septic Tank

A septic tank is a horizontal continuous flow

sedimentation tank. Here the sewage is allowed to move very slowly so as to

retain for a period sufficient to develop 60–70% of suspended matter to settle

in the form of sludge. Lighter solids float to the surface and combine with

grease and fat and form floating scum. The scum and sewage are allowed to stay

for a period of 7 months during which period complete decomposition takes place

through a process called sludge digestion. The volume of sludge is also gets

reduced for easy disposal. The effluent from the septic tank has a very bad colour.

It is dark in colour with fine solid particles and has to be disposed of with the utmost care. A schematic layout of a septic tank is shown in Fig. below.

A septic tank is constructed in such a way so

as to prevent direct current between the inlet and the outlet. This provides a better sedimentation and is achieved by using T-pipes

Septic tank

with submerged ends as inlet and outlet. As

an alternative, baffle walls may be provided. The T-pipe or the baffle at the

outlet also helps in retaining the scum in the tank. A certain quantity of scum

is needed to hold back odours and to create a form of heat insulations which in

turn aids the bacterial action. Usually, a manhole is fixed on the RCC cover

slabs. The tank cover allows keeping the sewage warm, lessening odour, etc.

Gases are separately removed through a vent pipe. Sludge is removed

periodically.

Septic tanks are to be located at a place

that is exposed to the sky and accessible for cleaning. The sewage in a septic

tank can be taken as only a primary treatment effect. Before disposal, the

effluent needs a secondary treatment. The septic tank has only a restricted use

in practice, such as schools, hospitals, small residential colonies and other

public institutions where sewers are not yet laid.

2.

Soak Pit and Leaching Cess Pool

The putrescible and highly odorous effluent

from the septic tank requires to be properly treated and disposed. The methods

of disposal are:

(i) Sub-surface irrigation employing

absorption field method.

(ii) Discharge into other soil absorption

systems as soak pit or seepage pits and leaching cess-pools.

Sub-surface irrigation is also termed land

infiltration. It is the application of sewage or its effluent into the land

through a system of open-jointed pipes or drains placed near the surface of the

ground and thereby enabling the effluent to percolate into the surrounding

soil. A soak pit is a covered pit through which the effluent is allowed to be

soaked or absorbed into the surrounding soil. The pit may be empty or filled up

with brick or stone aggregates

1. Brick

lining with dry joints

2. Outer

casing with coarse aggregates (7.5 cm thick min)

Soak

pit

A leaching cesspool is a pool such that the top portion acts as an absorption

field and the bottom as a septic tank. This is done by providing open-jointed

lining at the upper portion which enables the sewage effluent to the easily

dispersed to the surrounding soil. The bottom portion is of the solid wall which

functions as a septic tank

SOURCE:

BUILDING CONSTRUCTION MATERIALS AND TECHNIQUES | P. PURUSHOTHAMA RAJ

If you find

This information is helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment