LIFTS AND ESCALATORS

Elevators or lifts

Elevators are used in

buildings having more than four storeys. They are used for providing vertical

transportation of passengers or freight. They can be either electric traction

elevators or hydraulic elevators. Electric traction elevators are used

exclusively in tall buildings. Hydraulic elevators are generally used for

low-rise freight service which rises up to about six storeys. Hydraulic

elevators may also be used for low-rise passenger service..

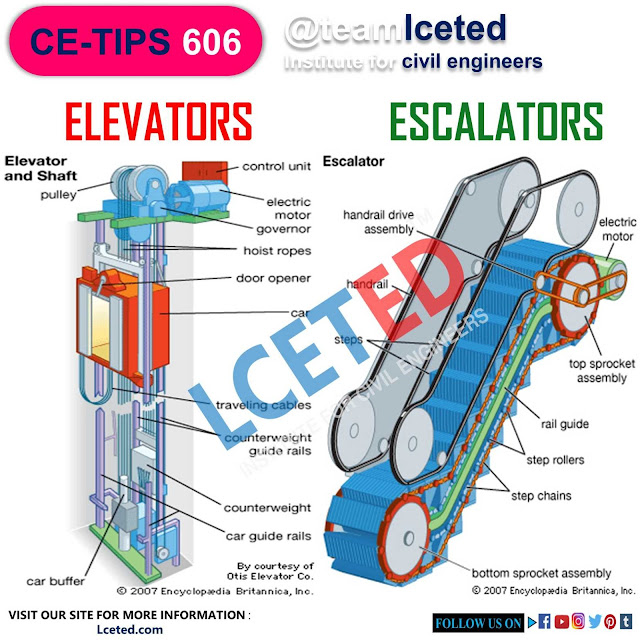

The different components of

an electric traction elevator are the car or cab, hoist wire ropes, driving

machine control equipment, counterweight, hoistway rails, penthouse and pit.

The car is the load-carrying element of the elevator and a cage of light metal

supported on a structural frame, to the top of which the wire ropes are

attached. The ropes raise and lower the car in the shaft. They pass over a

grooved, motor-driven sheave and are fastened to the counterweights. The paths

of both the counterweights and the car are controlled by separate sets of

T-shaped guide rails. The control and operating machinery may be located in a

penthouse above the shaft or in the basement. Safety springs or buffers are

placed in the pit, to bring the car or counterweight to a safe stop. For elevators

serving more than three floors, means should be provided for venting smoke and

hot gases from the hoistways to the outer air in case of fire. Vents may be

located in the enclosure just below the uppermost floor, with direct openings to

the outside or with non-combustible duct connections to the outside. The vent area

should be at least 35 per cent of the hoistway cross-sectional area.

Design considerations

The

key considerations which affect elevator system design are:

· Number

of floors to be served

· Floor-to-floor

distance

· Population

of each floor

· Location

of building

· Specialist

services within the building

· Type

of building occupancy

· Maximum

peak demand in passengers per 5-minute period

Design parameters

There are numerous parameters that can be used to judge elevator system performance. The principal one is based on the quality of service and quantity of service.

The ‘quality of service (or interval)’ is related

fundamentally to the time interval a passenger has to wait. It can also be said

as the expected interval (in seconds) between the arrivals of elevators in the

main floor. For a large building, the quality of service can be categorized as

i. average interval 20–25 seconds – excellent

ii. average interval 35–40 seconds – fair

iii. average interval 45 seconds – poor

The ‘quantity of service (or handling capacity)’ of a

system is expressed in the elevator industry design terms as a function of the expected building population. A large building with a single tenancy usually

provides heavier peak flows than those with multiple tenancies.

The following handling capacity should be used as a

basis for design to meet up morning peak. Single tenancy – 15–25 per cent of

the total building population entering in a 5-minute period. Multiple tenancies –

10–15 per cent of the total building population entering in a 5-minute period.

Location of elevators

The most efficient method of locating elevators to serve

an individual building is to group them together. A group has a lower average

interval between car arrivals than a single elevator.

Groups

should be located:

i. For easy access to and from the main building

entrance.

ii. Centrally for general ease of passenger journey.

If a building has areas that give long distances to the

central group elevator, then it may be efficient to provide an additional

elevator for local areas.

Ramps

They are sloping surfaces

used to provide an easy connection between the floors. They are especially

useful when a large number of people or vehicles have to be moved from floor to

floor. They are usually provided at places such as garages, railway stations,

stadiums, town halls, office buildings and exhibition halls. Sometimes, they are

provided in special-purpose buildings such as schools for physically

handicapped children. They should be constructed with a non-slippery surface.

Ramps are generally given a

slope of 15 per cent. But a slope of 10 per cent is usually preferred. The

space required for ramps is more. The ramp need not be straight for the whole

distance. It can be curved, zigzagged or spiralled. Ramps and landings should

be designed for a live load of at least 21.2 kg/cm2. The minimum width of

pedestrian ramps is 75 cm for heights between landings not exceeding 3.6 m. Landings

should be at least as wide as the ramps. Powered ramps, or moving walks,

carrying standing passengers may operate on slopes up to 8° at speeds up to 60

m/min and/or slopes up to 15° at speeds up to 47 m/min.

Escalators

These are powered stairs.

They are used when it is necessary to move a large number of people from floor to

floor. These stairs have continuous operation without the need for operators.

These escalators are in the form of an inclined bridge spanning between the

floors. The components of an escalator are a steel trussed framework, handrails and an endless belt with steps. At the upper ends of an escalator are a

pair of motor-driven sprocket wheels and a worm gear driving machine. At the

lower end is a matching pair of sprocket wheels. Two precision-made roller

chains travel over the sprockets pulling the endless belt of steps. Escalators

are reversible in direction. They are generally operated at a speed of 30 or 40

m/min. The slope of stairs is standardized at 30°. For a given speed of travel, the

width of steps determines the capacity of the powered stairs.

Escalators should be

installed where traffic is heaviest and where it is convenient for passengers. In

the design of a new building, adequate space should be allotted for powered

stairs. Structural framing should be made adequately to support them.

Escalators are generally

installed in pairs. One of them is used for carrying upgoing traffic and the

other for traffic moving down. The arrangement of escalators in each storey can

be either parallel or crisscross. The criss-cross arrangement is more compact. It

reduces the walking distance between stairs at various floors to a minimum. This is

why the criss-cross arrangement is preferred over the parallel arrangement.

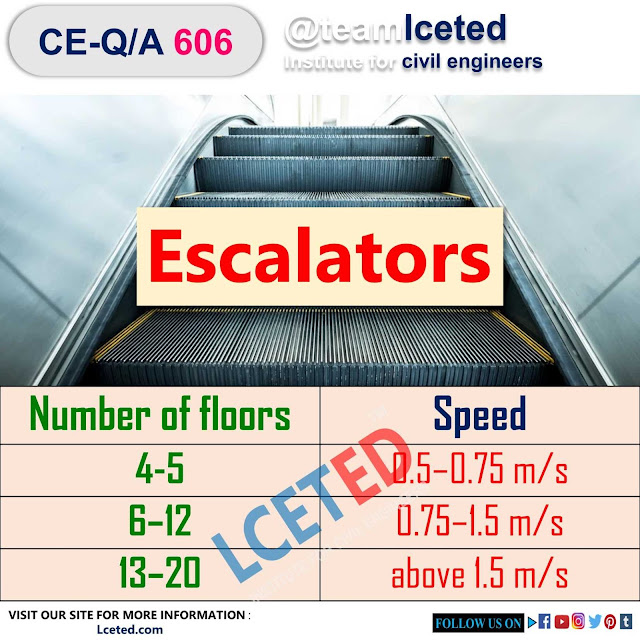

|

Number of floors |

Speed |

|

4-5 |

0.5–0.75 m/s |

|

6–12 |

0.75–1.5 m/s |

|

13–20 |

above 1.5 m/s |

If you find

This information helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment