In this article, you will be able to know about Shoring

and its components, Factors that determine the design and method of shoring, Procedures

for window/door shore and a vertical shore. Positions and functions of the

members of a shoring team.

WHAT IS SHORING?

Temporary

support for a damaged, collapsed, or partially collapsed structure is unstable,

requiring victims and rescue crews to carry out low-risk search and rescue

operations.

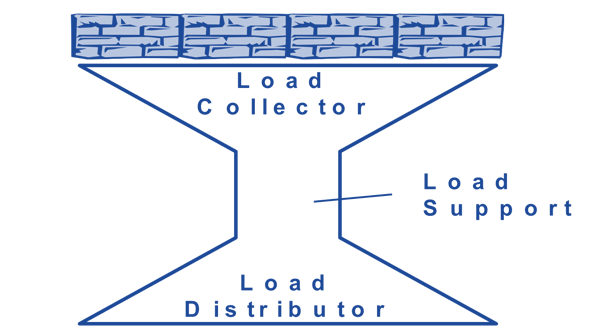

Shoring

follows a “Double-Funnel

Principle”, means that a shore collects a load, channels it and

redistributes it safely to another surface or structure that can support it.

COMPONENTS OF SHORE

Soleplate: Provides a

foundation for the shoring system by supporting the weight being transferred from

above and distributes it over a wider area.

Header beam: collects the weight

from above and spreads it throughout the shoring system.

Post:

Supports

the weight collected by the header and transfers it to the sole plate where it

is distributed.

Diagonal bracing: Locks the entire shoring system together as

one unit, supporting against possible eccentric loads. It is the last component

to be installed.

Gusset

plate: A small piece of 13 mm or 18 mm plywood nailed to the top and bottom of

posts to aid in placement of the header and secure the posts to the header and

soleplate.

Wedges/shims: Two wooden inclined

planes married together and placed under the bottom of the posts. These provide

compression for the shoring system. The shim is a single wedge used to fill in

gaps above the shoring system.

Cleat: A 5cmx10cm wooden piece

nailed to the post and header or sole plate to secure the shoring.

or

A small piece of wood used to secure other

parts of a shoring system.

TYPES OF SHORING

· Vertical

Shoring

· Window/Door

Shoring

Other Types of Shoring

· T-Spot

Shoring

· Raker

Shoring

· Laced

Post Shoring

· Horizontal

Shoring

· Trench

shores

· Pneumatic

shores

·

Improvised Bamboo shoring

DETERMINING FACTOR TO CHOOSE SHORING TYPE

A

variety of factors will determine what method of shoring is required in a

particular situation.

·

Weight of

construction materials

·

Weight of

the structural elements to be supported

·

The normal

load capacity of the existing undamaged structure

·

Condition

of the structure to be supported

·

Condition

of the foundation and floor/surface angle to determine the stability of shoring

·

Availability

of shoring material

·

Lateral and

vertical instability

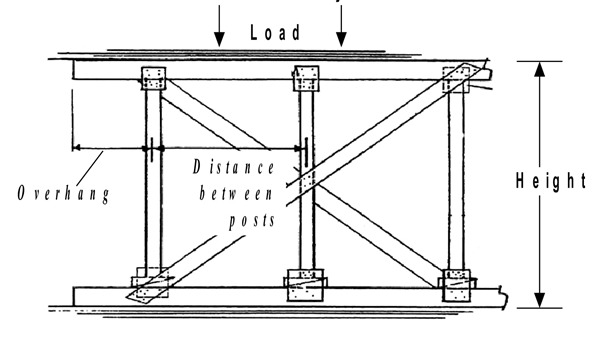

VERTICAL

SHORE SPECIFICATIONS

WITH

10 X 10 cm POST, HEADER AND SOLE PLATE

|

Maximum

Height |

Maximum

Distance Between Posts |

Maximum |

Maximum

Height |

|

2.5 m ( 8’ 0”) |

1.25 ( 4’0”) |

60 cm ( 2’0”) |

3,600 kg ( 8,000 lbs.) |

|

3.0 m ( 10’0”) |

1.50 ( 5’0”) |

80 cm ( 2’6”) |

2,270 kg ( 5,000 lbs.) |

|

3.7 m ( 12’0”) |

1.80 ( 6’0”) |

90 cm ( 3’0”) |

1,600 kg ( 3,500 lbs.) |

Density (weight) of

common building materials

Concrete = 2403 kg/m3

Masonry = 2002.5 kg/m3

Wood = 560.7 kg/m3

Steel = 7849.8 kg/m3

Concrete / Masonry

Rubble = 478.8 Pa

STEPS OF VERTICAL SHORE

1. Determine

where to erect the vertical shore.

2. Measure

and cut sole plate and header.

3. Measure

and cut the posts to the proper height.

4. Attach

cleats or gusset plates to the header and posts, on opposite ends and opposing

sides.

5. Install

the posts and the header on top of the soleplate to support the damaged

structural element

6. Install

a set of wedges under the bottom of each post

7. Attach

cleats or gusset plates on opposite ends and opposing sides of the soleplate

and posts and nail in place

8.

Attach the diagonal braces to each side of

the vertical shore

STEPS FOR WINDOW AND DOOR SHORE

• Locate

where to erect the window/Door shore.

• Measure

the soleplate to cut

• Measure

the header to cut

• Measure

and cut the posts to the proper height

• Install

the soleplate with a set of wedges

• Install

the header with a set of wedges

• Install

the posts and wedges

• Attach

the cleats and/or gusset plate

• Confine

the wedges

• Install

diagonal braces(when applicable)

OTHER TYPES OF SHORING

Several

additional types of shores can be used in collapsed structures, though they

will not be taught in this course. Some examples include:

T-Spot Shore: The

main purpose of the T-shore is to initially stabilise damaged floors, ceilings

or roofs, so that the more substantial shoring can be constructed at less risk.

This shore is quickly placed and only temporary, also used during quick extrication

of a victim.

Raker Shore: A

triangular system of shoring used to support leaning or unstable walls or

columns. Rakers must always be installed in series; at least two must be

erected in any given situation.

Laced Post Shore: A

high-capacity, four-post system that is used to support sagging(Hanging down)

floors and ceilings, or other overhead hazards. It can be used as a “SAFE HEAVEN”.

Horizontal Shore: Used

to stabilise a damaged wall against another undamaged wall in hallways,

corridors or between buildings.

Members and Functions of Shoring team

If sufficient manpower is

available, two separate SIX-person groups can be used to organize a shoring

group, with one team as an assembly team and the other as a cutting board.

However, a team may be

required to perform both sets of duties.

ASSEMBLY GROUP

Shoring

Officer (Rescue Squad Officer): Is responsible for the

process. Works with structural experts (if available) to determine where to

place the shore. If a security guard cannot be assigned, the shore officer will

also accept the role.

Measurer: Measures

all shoring components and publishes information to the layout person of the

cutting board.

Two

Shorers: These work together assembling and erecting shores in

place.

Safety: Responsible

for the overall security of the assembly committee.

Runner: Ensures

that tools, equipment and shoring materials are moved from the primary access

point to the shoring site and help set up shores as needed.

CUTTING GROUP

Cutting

Group Officer (Rescue Squad Officer): Responsible for selecting

the cutting site. The site should be close to the showing function. The cutting

board officer doubles as the safely.

Layout:

Sets up the cutting station and records measurements. Performs all measuring

and layout of angles.

Feeder: The

measured and marked shoring material from the layout to the cutter helps to

protect it while moving and feeding and cutting.

Runner:

follow the requirements related to shoring from shoring station to shoring

site.

Cutter: Measured

materials to be cutted.

Tools

and equipment person: Responsible for monitoring the directions

in which materials and equipment are to be placed and moving, and all

equipment. This person has been appointed to both the cutting committee and the

assembly committee.

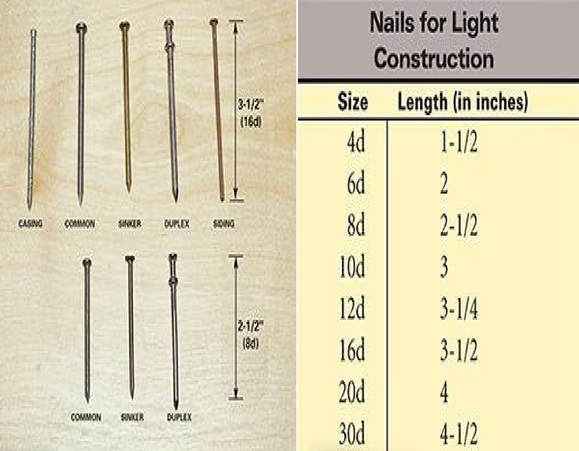

NAIL SPECIFICATIONS

Common nails of two sizes

will be used For CSSR,

All plywood (Gusset plates)

should be nailed using 8D common nails only.

All dimensional wood (100mmx100mmx1800mm)

should be nailed using 16d

Example: For 8d nail

D= diameter of nail (?),

l= length (7.5cm)

x= size of nail (8)

D = l/x • D= 7.5cm/8 = 9.3mm

If you find

This information

helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment