WHAT ARE THE REQUIREMENT FOR CONCRETE PRODUCTION, TRANSPORTATION, AND PLACEMENT

It is important for the Site Engineer / Site Supervisor engaged in Civil Engineering construction that the required quality of the work should be obtained while executing the work. Out of the total Civil work, concreting constitute the major part of the work hence required to exercise due care while production of concrete either through a Batching Plant or Concrete mixer, transportation of concrete either manually or mechanically by transit mixers and placement of the concrete to the desired location in a pour either manually or machinery i.e by crane or through a concrete pump or placer booms or through a chute. Awareness regarding the requirement at every stage is to be decided based on the requirement and mode of production/transportation/placement methods for concrete. Following are few areas requirements are listed for exercising care by Site Engineer for the above for effective and desired output.

WHAT CARE REQUIRED DURING THE PRODUCTION OF CONCRETING

The care required during the production of concreting depends on various factors.

1. Based on the production of the concrete.

a) Using concrete mixtures

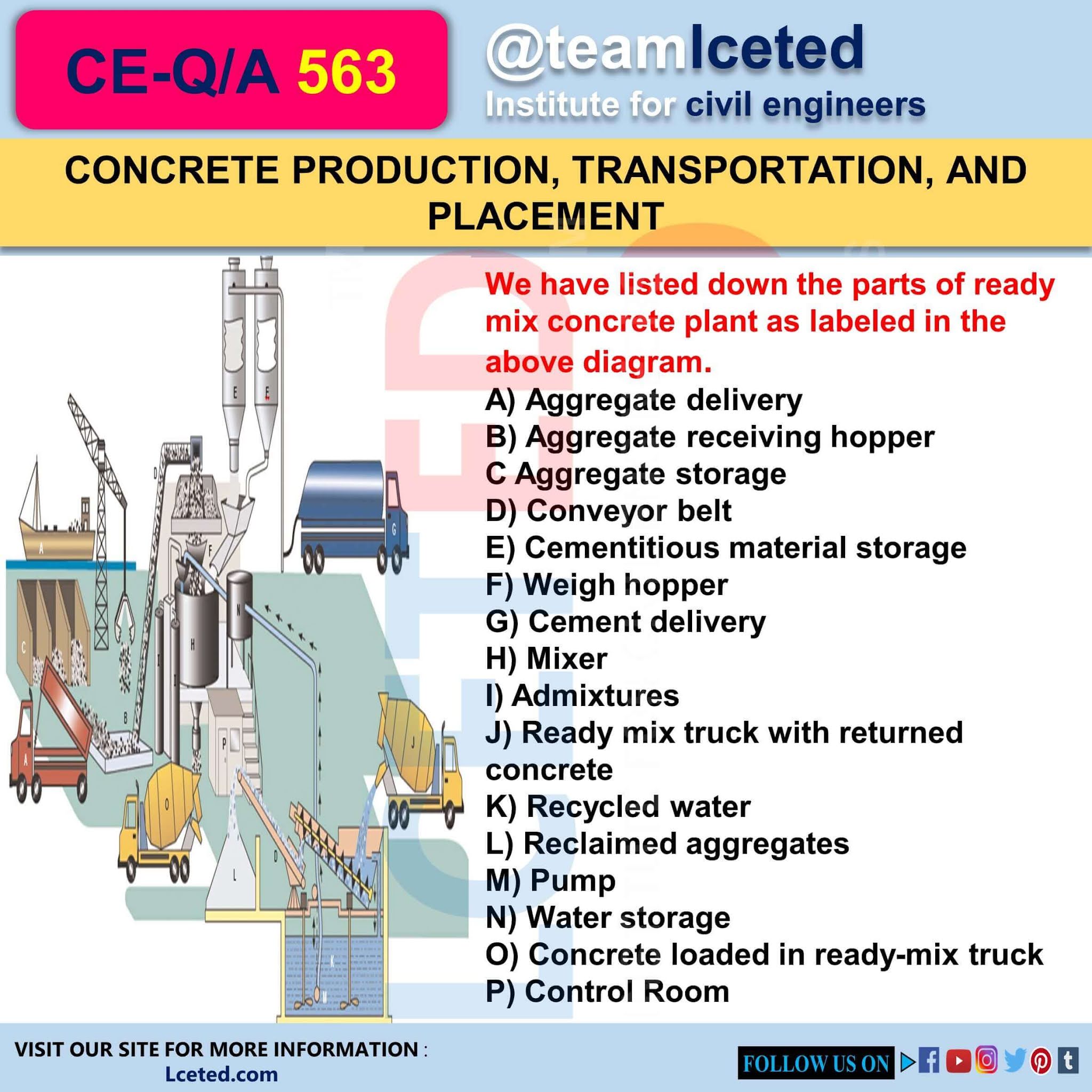

b) Using batching plants.

2. Depending on the weather condition i.e. is hot weather concreting or cold weather concreting.

3. Based on the time of concreting i.e. concreting done during day or night.

4. Based on the distance of batching plant from the point of placement

5. Based on the mode of transportation proposed i.e. manual / through transit mixture.

6. Based on the mode of placement of concrete i.e. by manual/ by crane / by concrete pump/placer boom / by chute etc.

7. Based on the Rate of pour required.

8. Based on the vertical drop of concrete from batching plant into transit mixture.

In addition to the above site engineer required to ensure the following based on the requisition of concrete received for the production of concrete.

· Availability of tested and approved construction material in required quantity.

· The safe access for transportation of construction material to batching plant / concrete mixture.

· Availability of power supply / DG supply/diesel fuel etc for running the batching plant/mixture for the desired duration.

· Based on the past record of batching plant /mixture for production of concrete for no. of running hours / cumulative concrete production in cum., availability of spare parts to be ensured which needs frequently repair/replacement to avoid any delay during concreting.

· Availability of supporting machines like welding arrangement, skilled/unskilled crew for repairing the system.

· Proper calibration of batching plant / weigh batcher prior to starting the work. This is generally done at fixed frequencies.

· Required rate of pour.

· Ensuring safety aspects at batching plant.

· Proper illumination and communication system at batching plant for effective coordination with engineers at point of placement.

WHAT CARE REQUIRED DURING TRANSPORTATION OF CONCRETE

The care required during the transportation of concrete depends on various factors:

· Mode of transportation, i.e based on the mode of transportation proposed i.e. manual / through transit mixture.

· Based on the distance of batching plant from the point of placement.

· Based on the mode of placement of concrete i.e. by manual/ by crane / by concrete pump/placer boom / by chute etc.

· Depending on the weather condition i.e. is hot weather concreting or cold weather concreting.

· Based on the required rate of pour.

· Based on stand by the arrangement of transit mixers.

· Based on arrangement for the availability of fuel, proper air pressure in tyres condition of transit mixers.

· Based on safe access from batching plant to point of placement and necessary turning areas for transit mixers safely at the site.

· Walkie - Talkie to be provided in transit mixers for effective coordination.

· Restriction of travelling speed of loaded and empty transit mixers

· Ensure availability of water in the water tank of transit mixers for immediate cleaning after concreting is done.

· Sun protection of transit mixers and their pipes with gunny bags and ensuring the wetness of the same.

CARE REQUIRED DURING PLACEMENT OF CONCRETE

It is the most important criteria of concrete since it decides the final quality and strength of concrete is structures. The cares required during the placement of concrete are as follows:

· Required consistency to be maintained from the point of production to point of the place. RPM of transit mixture should be around 4-5 RPM.

· Ensure safe access for labours / skilled workers.

· Ensure planned arrangement of the layout of the concrete pipe route.

· Ensure Sun / Rain protection for green concrete.

· Ensure proper arrangement of vibratos.

· Ensure the location of EP’s / Water stop/level of concrete etc as per drawing during concreting.

· Ensure type of finish and slope required in concrete.

· Ensuring the green cutting application within planned duration after concreting is done.

· Ensure that no cold joints should form.

· Use of cement, slurry to maintain the concrete green in case of delay in receiving the successive batch of concrete at site. Keep the check on the time taken from batching plant to the time at the point of placement w.r.t consistency and temperature.

· Avoid over vibration in concrete.

· Avoid the vibration of the initially hardened layer over which new concrete is been placed.

· Maintain all safety aspects, particularly while working in height and hazardous area.

· Ensure proper illumination and communication.

· Have leadership quality during difficult situations at site especially work done in night hrs / total power cut situation / during any accident at site / during any industrial relation problem at the site.

If you find

This information helpful please share it.

No comments:

Post a Comment