CHAIN SURVEYING | PRINCIPLE OF CHAIN SURVEYING | TERMS USED IN CHAIN SURVEYING | ACCESSORIES USED | FIELDWORK IN CHAIN SURVEY | CODE OF SIGNALS USED IN CHAIN SURVEY

CHAIN SURVEYING

A

chain is a device for taking linear measurements in the field. Chain surveying

is accomplished by taking linear measurements only.

WHERE CHAIN SURVEY IS SUITABLE AND WHERE NOT?

BASIC PRINCIPLE OF

CHAIN SURVEYING

The principles followed in chain surveying are:

a.

The whole of the area to be surveyed is divided into a skeleton framework

consisting of a number of well-connected networks of ‘well conditioned’

triangles.

b.

The details are to be located with respect to the sides of the triangles or any

other subsidiary lines running between the sides by taking lateral measurements

called ‘offsets’.

SKELETON FRAMEWORK

FOR CHAIN SURVEYING

To

decide on the best planning of the skeleton framework for chain surveying a

field, one should base his judgment on the minimum labour to produce a map with

the required details and minimum distortion. The following points should be

taken care of:

a.

Through reconnaissance, it should be ascertained that due to the presence of

thick hedges, trees or any other obstacles, there should not be any obstruction

to the laying of chain along with the framework, taking the necessary measurements

and the intervisibility along the lines of the framework.

b.

Preferably a long line should run through the centre of the area to form a baseline on which well-conditioned triangles should be based. The baseline should

prevent the relative rotation of the tri- angles due to errors in the

measurements when they are plotted on the map. This arrangement for the

framework will limit the distortion in the map to a minimum.

c.

The lines should run closer to the details, which are to be described with

respect to them by taking lateral measurements called ‘offsets’.

d.

To avoid long offsets additional lines should run between the sides of the

triangles of the framework.

e.

There should also be some other additional lines for checking the accuracy of

the measurements.

f.

Care should be taken so that no portion of the framework goes beyond the boundary of the area to be surveyed.

TERMS USED IN CHAIN

SURVEYING

a. Main station: The main station is a point in chain survey where the two sides of a traverse or

triangles meet. These stations command the boundaries of the survey and are

designated by capital letters such as A, B and C.

b. Tie stations or subsidiary stations: Tie station is a station on a survey line joining main

stations. These are helpful in locating the interior details of the area to be

surveyed and are designated by small letters such as a, b and c.

c. Main survey line:

The chain line joining two main survey stations is called the main survey line.

d. Tie line or subsidiary line: A chain line joining two tie stations is called a tie

line, such as jk. It is also called an auxiliary line. These are provided to locate

the interior details, which are far away from the main lines.

e. Baselines:

It is the longest main survey line on fairly level ground and passes through

the centre of the area. It is the most important line as the direction of all

other survey lines are fixed with respect to this line.

f. Check lines: A check line or proof line is a line that is provided to check the accuracy of

the fieldwork. The measured length of the check line and the computed one

(scaled off the plan) must be the same.

g. Offset:

It is the distance of the object from the survey line. It may be perpendicular

or oblique.

h. Chainage:

It is the distance of a well-defined point from the starting point. In chain

surveying it is normally referred to as the distance of the foot of the offset

from the starting point on the chain line.

FIELDWORK IN CHAIN

SURVEY

Suppose

a plan is required for a small area as shown in Figure The surveyor should first

of all examine the ground to ascertain as to how they work can be arranged in

the best possible manner. This is known as a reconnaissance survey. In this

process, the surveyor selects suitable ground points to be used as stations

like A, B, C, etc. Stations are arranged so that the entire area may be

controlled from these points and all the main survey lines AB, BC, CD, etc. run

near to the boundaries. The survey lines should not be many and lie over flat

level grounds as far as possible. The triangles formed by survey lines should

be well-conditioned.

The

main survey lines are measured with a chain and offsets are taken to the

boundaries. Offsets are taken wherever there is a bend or any special feature in

the boundary. In cases, where the boundary forms a smooth curve offsets are

taken at the end of each chain. Offsets should be short, particularly for

locating important details.

The

lengths and positions of offsets being known, the boundaries can be plotted to

their shapes. The other details which are deep inside the area, such as a well

as shown in Figure, can be located by selecting tie stations, drawing tie lines

and taking offsets to the ground features.

SURVEY CHAIN

Gunter,

revenue, engineer and metric chains are the various types of chains, which are

normally used for surveying. The chains are mostly divided into 100 links.

While the gunter’s chain is 66 ft long, the revenue chain is 33 ft long and the

engineer’s chain is 100 ft long. Metric chains are either 30 m or 20 m in

length.

The

different parts of a chain are shown in Figure 26.2. The part marked 1 is a

brass handle that contains a semicircular groove at its end for

accommodating arrows during chaining. Parts marked 2 and 3 are the collar and

eye bolt. 2 and 3 form a swivel joint with the brass handle. Part 4 is a

circular ring that connects the end link marked 5 with the eye bolt. The links

are connected with each other with three circular rings marked 6.

All

links except the end links are of equal lengths. The link length measures the

distance between the centres of the central rings of the joints on either side

of the link. The end link forms the complete link length with the brass handle.

The end link length measures the distance from the end of the handle to the

centre of the central ring of the joint next to the end link. The length, of

course, is to be measured while the chain is held straight.

The

swivel joint allows rotation of the handle preventing the deformation due to

twist in the end link. The three-ring joints provide enough flexibility to

prevent the deformation of the links by bending.

For

the ease of readability of the chain, different brass tag marks or tally marks

are provided in it at definite length intervals, identical tags being placed at

identical distances from either end of the chain. This provides an

opportunity to read the length on the chain at any of its points from either of

its ends (marked 8 in Figure).

All

links are made out of SWG No. 8–No.12 wires of galvanized mild steel, in

accordance with IS:1492-1970, having a diameter of 4 mm usually. The material

is sufficiently soft and ductile to withstand hammering when the bent links are

to be rectified. It may be noted that a chain with 100 links will have 99 joints

between the links and two joints between the handles and the end links. There

are 4 x 101 = 404 pairs of wearing surfaces at those joints.

|

| Components of a chain |

FOLDING AND

UNFOLDING CHAIN

Unless

great care is taken in folding and unfolding a chain, the links of the chain

may bend and the rings of the joints may be deformed, making the length of the

chain different from its standard length. This will introduce errors in the

measurements when employed in the survey. Moreover, the chain cannot be boxed

without folding it in a proper way.

Before

putting it to use the chain bunch is taken out and held in one hand. The rest

of the bunch is to be spread on the ground. One of the handles is to be

released now and the chain is to be dragged when it is unfolded.

After

its use, the chain is to be folded before it is put into its box. The central

ring at the middle of the chain or the tally mark there and both the handles of

the chain are put together at one end and the central rings quarter length,

that is between 25th and 26th links and at 3 quarter length, that is between

75th and 76th links are put together at the other end. The chain laid and

folded in this way on the ground will have bunches of 4 links lying side by

side along the length. Each bunch of four is to be held and folded over to the

next bunch alternatively to complete the folding of the chain.

TAPES

Tapes

are available in a variety of materials, lengths and weights. The different

types of tape in general use are explained below (Figure).

a. Cloth or linen tape: These are closely woven linen or synthetic material and

are varnished to resist moisture. These are available in 10–30 m in length

and 12 to 15 mm in width. The disadvantages of such tapes are that it is

affected by moisture and gets shrunk, its length gets altered by stretching and

it is likely to twist and does not remain straight in strong winds.

b. Metallic tapes: It is a linen tape with brass or copper wires woven

into it longitudinally to reduce stretching. As it is varnished, the wires are

not visible. These are available in 20–30 m length. It is an accurate

measurement device and is commonly used for measuring offsets. As it is

reinforced with wires, all the defects of linen tapes are overcome.

c. Steel tapes: These are 1–50 m in length and 6–10 mm in width. At the

end of the tape a brass ring is attached, the outer end of which is the zero

points of the tape. Steel tapes cannot be used in grounds with vegetation and

weeds.

|

| Types of tapes |

Invar tape:

This is made of an alloy of nickel (36

per cent) and steel having a very low coefficient of thermal expansion (0.122 x10−6/°C). These are available in lengths of 30, 50 and 100 m and

in a width of 6 mm. The advantages and disadvantages of an invar tape are as

follows.

ADVANTAGES

i. Highly precise.

ii. It is less effective

by temperature changes when compared to other tapes.

Disadvantages

i. It requires much

attention in handling.

ii. It is soft and so

deforms easily.

PVC coated fibre glass tapes

are most common nowadays, as they are more durable and weatherproof.

MARKING STATION POINTS ON THE GROUND IN CHAIN SURVEYING

On a normal ground, the

station points are to be marked by driving wooden pegs into the ground. Made of

hardwood the wooden pegs are 25 mm x 25 mm in cross-section and 150 mm in

length. When driven, at least 50 mm should be above the ground.

ACCESSORIES USED

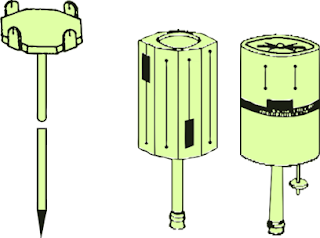

i. Ranging rod:

2-3 m in length, with well-seasoned timber made into a rod of 30 mm diameter,

alternatively painted red and white or black and white over a long interval

of 200 mm. The ranging rod is provided with an iron shoe at its bottom and

carries a 250 mm x 250 mm flag coloured red and white or yellow and white to

make it conspicuous from a distance. It is used to find out the points lying on

a line, i.e., in ranging a line. It is also used to mark the station points

when the wooden pegs driven for the purpose are not visible from a working

distance (Figure).

| Ranging rods |

ii. Ranging poles:

These are ranging rods with longer lengths varying from 4 to 6 m. These are

employed to range long lines on undulatory grounds.

iii. Offset rods:

It is almost the same as the ranging rod with the only difference that here the

flag at the top is replaced by a stout ring or a hook for pulling or pushing the

chain. It is employed to take short offsets in ordinary works.

iv. Arrows:

Accompanying each chain are 10 arrows. They are also called marking chains or

pins and are used to mark the end of each chain during the process of chaining

(Figure).

v. Pegs:

Wooden pegs are used to mark the positions of the stations. They are made of

hard timber and are tapered at one end. They are usually 2.5 cm2 and 15 cm

long. But in soft grounds, pegs 40–60 cm long and 4-5 cm2 are suitable (Figure).

vi. Cross staff: The cross staff is used for finding the foot of the

perpendicular from a given point of a line and for setting out a right angle at

a given point of a line. There are three forms of cross staff, namely the open

cross staff, the French and the adjustable cross staff (Figure).

•

Open cross staff: The simplest form

of the cross staff is the open cross staff. It consists of the head and the leg.

The head is simply a wooden block octagonal or round around 15 cm side or diameter and 4 cm deep.

To find the foot of the

perpendicular from a given point to a given chain line, i.e., to take the

offset, the cross staff is planted or held vertically on the chain line where the

offset is likely to occur and turned until one pair of opposite slits is

directed to a ranging rod at the forward end of the chain line. Looking through

the other pair of slits, it is seen if the point to which the offset is to be taken is bisected. If not, the cross staff is

moved forward or backwards on the chain line until the line of sight through the

pair of slits at right angles to the chain line bisects the point.

|

| Arrow - chain survey |

|

| PEG |

|

| Different types of cross staff |

•

French cross staff: It consists of an

octagonal brass tube with slits on all eight sides. The base carries a socket

so that it may be fitted on the pointed staff when the instrument is to be used.

The sights being too close, it is inferior to the open type.

•

Adjustable cross staff: This may be used

for setting out angles of any magnitude. However, the results are only

approximate owing to the closeness of the sights.

RANGING A LINE – DIRECT

AND INDIRECT

Ranging a line means

establishing intermediate points on the line. This may be accomplished with

visual observations and ranging rods, looking through an instrument called

‘line ranger’ or looking through theodolite in precision works for ranging

long lines. The operation may be classified as follows:

i. Direct ranging

ii. Indirect ranging

i. Direct Ranging:

In direct ranging, the surveyor can observe and direct the person holding the

ranging rod to put the ranging rod at any intermediate point on the line being

ranged out.

ii. Indirect Ranging:

Here, the surveyor cannot find out any intermediate points on the line on his

own and has to depend upon the statement of a person at the end of the line and

also on the statement of the person carrying the ranging rod.

RANGING WITH RANGING

RODS

In Figures, A and B are two

station points. The line AC is to be ranged. At A and C, two ranging rods are to

be driven vertically. The verticality of the rods is to be assured with the

help of a plumb bob. If the rods at A and C are truly vertical, the surveyor

standing about 2 m behind A and looking along the

|

| Ranging a line |

line AC will find the vertical projection of the rod at C hiding behind the vertical projection of the rod at A, as shown in the figure. If the surveyor stands very near to A he may miss the vision for comparison. The surveyor will now send a man with a ranging rod to stand on the line AC at a distance less than one chain length from A. The surveyor should advise the man through hand signals to put a rod vertically on the line AC till he finds with his one eye closed and looking along with AC the vertical projections of both the rods hiding behind that of the rod at A.

Point B will then lie on AC. This way the other points may be ranged out.

CODE OF SIGNALS IN

RANGING

In the field, nothing should

be communicated through loud speaking because it will lead to exhaustion. The

following hand signals are therefore to be followed during the ranging of a

line

i. The rapid sweeping

movement of the right hand should mean long moved to the right. The slow

sweeping movement of the right hand should mean very short movement to the

right.

ii. Similarly, the

rapid sweeping movement of the left hand should mean long moved to the left

and the slow sweeping movement of the left hand should mean short movement to

the left.

iii. The right or the

left arm extended should mean to continue moving to the right or left

accordingly.

iv. The right arm up

and moved to the right should mean to make the rod vertical by moving the top

of the rod to the right. Similarly the left arm up and moved to the left means

to make the rod vertical by moving the top of the rod to the left.

v. Both the hands

raised above the head and then brought down should indicate that the position

of the rod is on the line AC.

vi. Both arms projected

forward horizontally and then brought down should conclude that the rod is to

be fixed at that position.

If you find

This information helpful, please share it.

Thanks! For reading the article.

No comments:

Post a Comment