DETAILED WET PROCESS OF CEMENT MANUFACTURING - LCETED

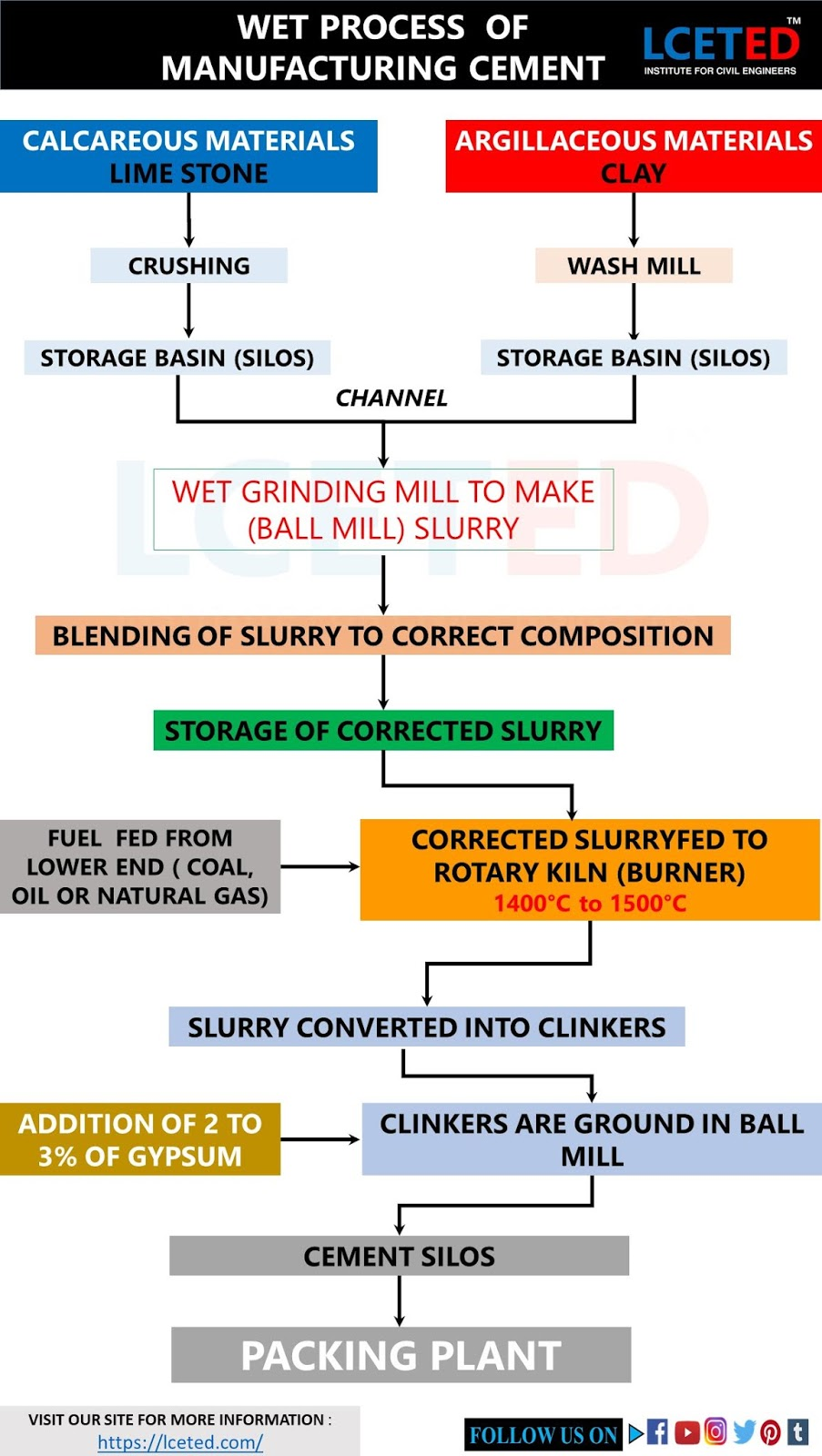

If the chalk is used in the wet process, it is finely broken and

spread in water in the wash mill. The wash mill is a circular pit with rotating

radial arms with rakes that break the solids into lumps. In a similar wash

mill, the soil is also broken and mixed into the water. Now the two mixtures

are pumped so that the mixture can be passed in a predetermined ratio and

passed through a series of screens. The resulting cement slurry flows into

storage tanks.

When limestone is used, the first blast it, then crush it into two progressively smaller crushers and then

pour into a ball mill with clay dispersed in water. The resulting solution is

pumped into storage tanks.

The slurry is a creamy

consistency liquid with a water content of 35-50% and a fraction of the material

approximately 2% larger than a 90μm sieve size. There are many storage tanks

provided to store the slurry. Settling of suspended solids prevented by

bubbling by compressed air or mechanical stirrers.

The slurry with the desired

lime content is transferred to the rotary kiln. This is a large refractory-lined steel cylinder up to 8 m in diameter and sometimes 230 m in length. The

steel cylinder rotates slowly around its axis and tilts slightly horizontally.

The slurry is supplied to the kiln at the top, and the pulverized coal is blown

by air blast at the bottom of the kiln at about 1450 °C. The coal used in the

kiln should not have too high ash content, as 220 kg of coal is used to make 1

ton of cement. It is worth considering the amount of cement.

ALSO READ: Difference Between OPC and PPC Cement | How to Make the Right Choice

The dry material goes

through a series of chemical reactions in the hottest part of the kiln, about

20-30% of the material becomes liquid, and lime, silica and alumina are

recombined. The fused mass turns the fuse into a ball with a diameter of 3 to

25 mm kn called as clinker. The clinker falls into a cooler that cools under

controlled conditions. Cooled clinker and 3-5% of gypsum are crushed in a ball

mill to the necessary fineness and then taken to storage silos, packed with

cement.

The kiln must work

continuously to ensure a steady regime and uniformity of the clinker. A

conventional, larger kiln in a wet process plant produces 3600 tons of clinker

per day.

Cement manufacturing by wet the process is energy-intensive, so it is uneconomical compared to dry process and

semi-dry process.

ALSO READ: DETAILED

MANUFACTURING PROCESS OF CEMENT

Advantages:

The wet process of cement production has the characteristics of simple

operation, low dust and easy transport. The slurry has good fluidity, good

homogeneity, and the quality of the clinker is improved. In addition, the

energy consumption of raw material grinding in wet processes is reduced by

almost 30%.

Disadvantages: The

heat consumption of the wet process is very high, generally between 5234-6490 J

/ kg and the consumption of the vulnerable areas of the ball mill is high.

Compared with other processing methods, the clinker produced by the wet process

has a lower temperature when leaving the kiln, so this method is not suitable

for producing clinker with a higher silica rate and higher aluminium-oxygen.

If you find

this information helpful please share

it.

Thanks! For

reading the article.

No comments:

Post a Comment