Cantilever

beams are elements that are supported at one end and carry a load at the other

end or are distributed along the unsupported part. To ensure that the structure

is static, the support must be fixed, which means that it can withstand forces

and moments in all directions.

The

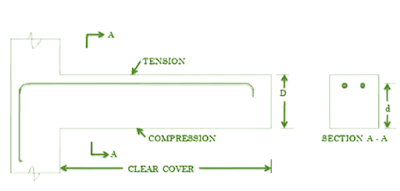

upper half of the cantilever beam thickness is subjected to tensile stress,

tendency to elongate the fibers, the lower half to compressive stress, tendency

to crush them. Beams may be raised outside their supports by a distance equal

to a quarter of the span between supports.

Cantilevers deflect more than most other types of beams

because they only rest at one end. This means that there is less support for

the load to be transferred.

A great

example of a cantilever beam is a balcony. A balcony is only supported at one

end, the rest of the beam runs over open space; there is nothing to support it

on the other side.

This

structural beam is widely used in the construction of bridges, towers and

buildings and can add a unique charm to the structure.

This article, explains some important structural steps and basic

concepts of a cantilever beam in construction.

How

to calculate Cantilever beam deflection?

Cantilever beam deflection

can be calculated in different ways, for example with simplified cantilever

beam equations or calculators and cantilever software.

Structural Behaviour of Cantilever Beam

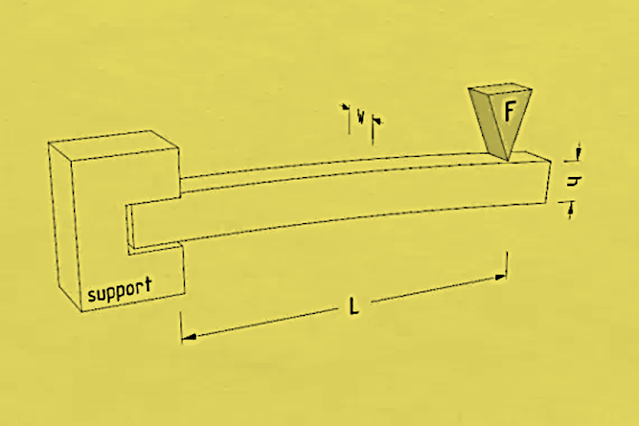

As shown in Fig-2 below, a

cantilever beam bends downwards when subjected to vertical loads. A cantilever

beam can be subjected to

· Point

load,

· Uniform

load

· Varying

load

|

| Fig--2: Cantilever Beam Bending Downwards Due to a Load 'F' at Free End |

Regardless of the type of

load, it bends downward creating an upward convexity. This flexion creates

tension in the upper fiber and compression in the lower fibres. Therefore, the

main reinforcement is provided to the upper fiber of the concrete beam, because

there is a high tensile stress as shown in Fig 4.

Cantilever Beam - Shear Force (SF) and

Bending Moment (BM) Diagram

The shear force of any part

of a cantilever beam is the sum of the loads between the section and the free

end. The moment of bending in a given section of a cantilever beam is the sum

of each moment according to the section of all loads acting between the section

and the free end.

Consider,

Cantilever beam AB of length 'l' subjected to a point load 'W' at the end B.

A section X-X at a distance 'x' from the free end B

is placed.

The shear force at section X-X is Rx, which is equal to W and

the bending moment of section X-X is

Mx, which is equal to W.x.

|

| Fig-3: Bending and Shear Force Diagram of Cantilever Beam with Point Load at Free End |

The shear force at fixed support A is determined by

holding the part at A,

Which gives the shear force Ra=W; and

Moment Ma = W.l.

Based on which the shear force and bending moment

diagram are developed.

The cantilever beam has a maximum

bending moment at the fixed end and decreases to zero at the free end. The

diagram of bending and shear forces is determined for all possible load

combinations in order to design a cantilever beam for a structure. The load

applied to the beam is a combination of dead load and live loads in accordance

with design standards.

Cantilever Beam Design

A cantilever beam is subjected to moment and shear

stresses under the action of structural loads. The purpose of any design

process is to safely transfer these stresses to support.

|

| Figure-4: Structural Behavior of Cantilever Beam |

The cantilever beam has a bending moment that varies from zero at

the free end to the maximum value at the fixed end support (Fig- 3). Therefore,

when designing the cantilever beams, the main reinforcement is provided to the

upper beam of the concrete beam to safely resist the tensile stress.

The maximum spacing of a cantilever

beam generally depends on the following factors:

·

Depth of cantilever

·

Load size, type and

location

·

Quality and type of

materials used

Generally,

for small cantilever beams, the span is limited to 2 to 3 m. But the depth can

be increased to increase the span or by using a steel or pre-pressed structural

unit. This structure can last a long time because it can be safely shifted to

the ground in the face of the moments created by the cantilever. Detailed

analysis and design of the structure will help to explore the feasibility of

cantilever beams at long intervals.

The

cantilever beam must be properly fixed or supported against the wall to

minimize the inverse effect.

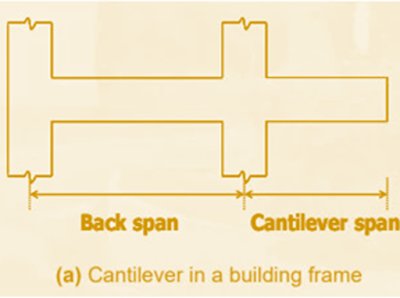

Uses of Cantilever

Beam in Construction

Cantilever beam elements are used in

the following applications:

· Construction of cantilever beams and balconies

·

Temporary cantilever

support structures

·

Freestanding radio

towers without guy-wires

·

Pergolas

construction

·

Construction of

lintel in buildings

|

| Fig-5: Applications of Cantilever Beam in Buildings and Bridge Girders |

·

In building

construction, there are various applications such as the cantilever beam, i.e.

gallery, roof, upward crane runway, or part of a building above and the sun

shed, shelves, large halls, exhibition buildings and weapons.

ADVANTAGES OF CANTILEVER BEAM:

This

beam has the following advantages;

· In

construction, these beams are simple.

· On

the opposite side, it does not need support.

· This

beam creates a negative bending moment, which counteracts the positive bending

moment of the rear spans.

· As

the beam is inserted into the cantilever arms, the gap will be larger than a

simple beam.

· Thermal

expansion and ground movement are much simpler to maintain because the beam

simply rests on the hands.

· Due

to their depth, the cantilever beams are very stiff.

DISADVANTAGES OF CANTILEVER BEAMS

·

The cantilever beams

are subjected to large deviations.

·

The cantilever beams

are subjected to large moments.

·

Strong fixed support

or backspan is essential to keep the structure stable

FAQs

What is a cantilever beam?

Cantilever

beams are elements that are supported at one end and carry a load at the other

end or are distributed along the unsupported part. To ensure that the structure

is static, the support must be fixed, which means that it can withstand forces

and moments in all directions.

What is the maximum span of cantilever beams?

Generally,

for small cantilever beams, the span is limited to 2 to 3 m. But the depth can

be increased to increase the span or by using a steel or pre-pressed structural

unit. This structure can last a long time because it can be safely shifted to

the ground in the face of the moments created by the cantilever. Detailed

analysis and design of the structure will help to explore the feasibility of

cantilever beams at long intervals.

How

to calculate Cantilever beam deflection?

Cantilever beam deflection

can be calculated in different ways, for example with a simplified cantilever

beam equations or calculators and cantilever software.

How does a cantilever beam behave under loads?

a cantilever beam bends

downwards when subjected to vertical loads. A cantilever beam can be subjected

to

· Point

load,

· Uniform

load

· Varying

load

Regardless of the type of

load, it bends downward, creating a pile upwards. This curve creates tension in

the upper fibres and contraction in the lower fibres. Therefore, during the

design of the cantilever beams, the main reinforcement is provided to the top

fibre of the concrete beams to safely withstand the tensile stress.

No comments:

Post a Comment