DETAILED DRY PROCESS OF CEMENT MANUFACTURING - LCETED

In

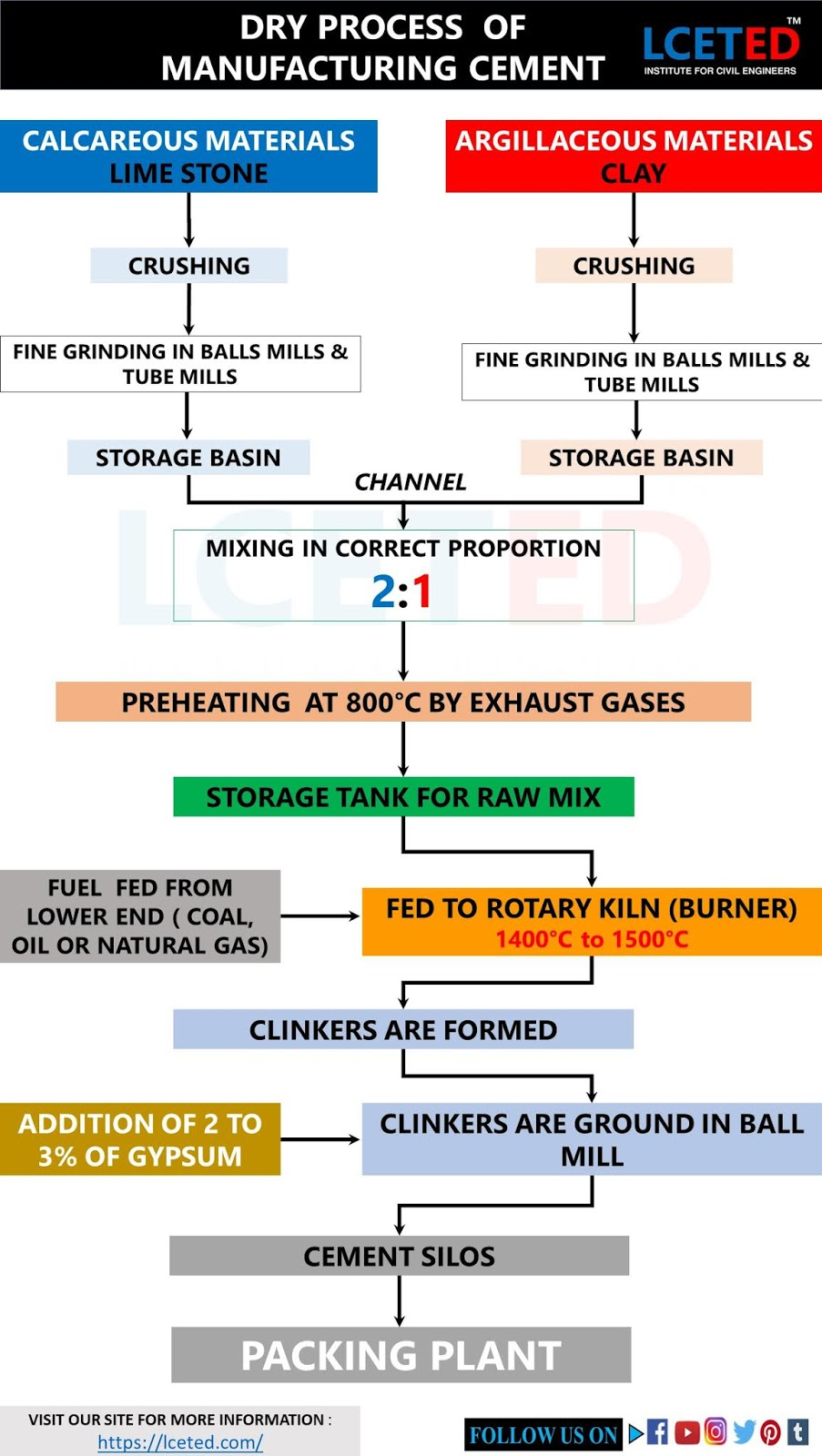

dry and semi-dry processes for the manufacture of cement, raw materials are

crushed and fed into the grinder in the correct proportions. The raw material

is dried and reduced in size to a fine powder in a grinder. Dry powder is

called a raw meal. Raw meals are pumped into mixing silos. Adjustment of the

proportions of materials required for cement manufacturing is made in silos.

|

| DRY PROCESS OF CEMENT MANUFACTURING |

The

raw meal is mixed by passing compressed air to obtain a uniform and intimate

mixture. Compressed air induces upward motion of the powder and reduces the

apparent density. The air is pumped on one quartile of the silo at a time and

this allows for apparently heavier material from the non-aerated quadrilateral.

Therefore the aerated powder behaves like a liquid and a uniform mixture is obtained

by alternately circulating all the quadrants for a total duration of about one

hour. Continuous blending is used in some cement manufacturing plants. The

mixed meal is further passed into the sieve and then fed into a rotating disk

called a granulator. About 12% water is added by weight to make mixed food into

pellets.

ALSO READ: Difference Between OPC and PPC Cement | How to Make the Right Choice

In the semi-dry process, the mixed meal is now sieved and fed into a rotating dish

called a granulator, which contains about 12% water by weight. In this

method, hard particles with a diameter of 15 mm are formed. This is necessary

because the cold powder does not allow the airflow and heat transfer required

for the chemical reactions to form cement clinker directly into the kiln.

The

pellets are baked hard in the pre-heating grate through hot gases from the

kiln. The pellets then enter the kiln where the temperature is around 1450 ° C.

The total coal consumption in this method is only about 100 kg, compared to the

requirement of about 220 kg for the production of one ton of cement in the wet

process.

The

dry material undergoes a series of chemical reactions in the hottest part of

the kiln and about 20 to 30% of the material is liquefied, and lime,

silica, and alumina recombination occurs. The fused mass turns the fuses into

balls of 3 to 25 mm diameter known as clinkers. The clinker moves to the cooler

where it is cooled to the control position. The cooled clinker and 3 to 5% of gypsum are crushed in the ball mill for required fine-graining and

then transported to the storage silo from where cement is bagged.

ALSO READ: DETAILED MANUFACTURING PROCESS OF CEMENT

The equipment used in the

dry process kiln is relatively small. The process is very economical. Methods

are commonly used to directly control the quality of clinker.

Advantages: The drying process feeds the raw materials directly

into the rotary kiln and as the moisture content of the raw materials is about

1% - 2%, the heat consumption required for moisture evaporation is saved.

Therefore, this method has the advantages of energy-saving, high production

capacity and stable output, which can meet the production requirements of large

cement plants. At the same time, the dry process eliminates less wastewater in

cement production. It is ideal for environmental protection. Nowadays, we call

the production line the new dry process cement production line with preheater

and precalciner, which is the direction of growth of dry process cement

production in future.

Disadvantages: Disadvantages of the drying process are inconsistent mixing of raw materials, high power consumption and high dust content in the workshop.

This information helpful please share it.

Thanks! For reading the article.

No comments:

Post a Comment