What Is The Compressive Strength?

Compressive strength is the

ability to carry loads of material or structure on its surface without any

cracking or deformation. An object under compression will reduce in size and,

under tension, the size will continue to lengthen.

Compressive Strength = Load /

Cross-sectional Area

IMPORTANCE

OF COMPRESSIVE STRENGTH IN CONCRETE

Concrete is a mixture of

sand, cement and aggregate. The concrete strength depends on the individual

compressive strength of its components (cement, sand, aggregates), the quality

of the materials used, curing methods, water-cement ratio, the ratio of air entrainment

mixture and many other factors. Effects of temperature.

The Compressive strength test helps us to know the overall strength and

the above factors. By conducting this test, one can easily determine the

strength psi of the concrete and the quality of the concrete being produced.

The Concrete Cube Test will

give compressive strength of concrete

which gives an idea of all the properties of concrete. By this unique test, we

can decide whether the concreting was done correctly or not.

The compressive strength of concrete ranges from 15

MPa (2200 psi) to 30 MPa (4400 psi) for residential concrete and is high in

commercial structures. Some applications use forces greater than 10,000 psi (70

MPa).

Must read: What Is Slump Cone Test | Procedure | Slump patterns | Slump Value | Observations | FAQ

PROCEDURE FOR TESTING THE COMPRESSIVE

STRENGTH OF CONCRETE CUBES

Purpose of the test to To

find compressive strength value of the concrete cube

Equipment

& Apparatus Required For The Test

PREPARATION OF CONCRETE CUBE SPECIMEN

All products should be

stored at around 27 C +- 3 C degree Celsius. Ensure there are no lumps in the

cement by mixing it uniformly with a trowel

Mixing

of concrete

Mix the concrete either by

hand or in a laboratory batch mixer

Hand

mixing

The process must be done on

the G.I Sheet (For Making Concrete) until a homogenous mix is obtained.

· First

mix fine aggregates and cement in dry state

· Second

Add coarse aggregates with equal distribution

· Finally

add the amount of water to the package until stability is reached.

Machine

mixing

The component should not be

rotated for more than 2 minutes and the following method should be followed

· Amount

of water

· coarse

aggregates 50%

· fine

aggregates

· cement

· coarse

aggregates 50%

Sample

casting (specimen)

The casting molds are rubbed

with grease on the inner side for easy removal. This sample should be poured in 3

layers (5 cm each) and mixed properly to avoid honeycomb formation.

Compaction

Using tamping rod Compact

each layer with not less than 35 strokes per layer. This tamping bar has the dimension of steel bar diameter 16mm and a length of 0.6m.

Age

of test

Compressive strength Cube

testing can be done in 1, 3, 7, 14 and 28 days. Sometimes, the strength of the

older ones is required, which is carried out at 14 to 54 weeks.

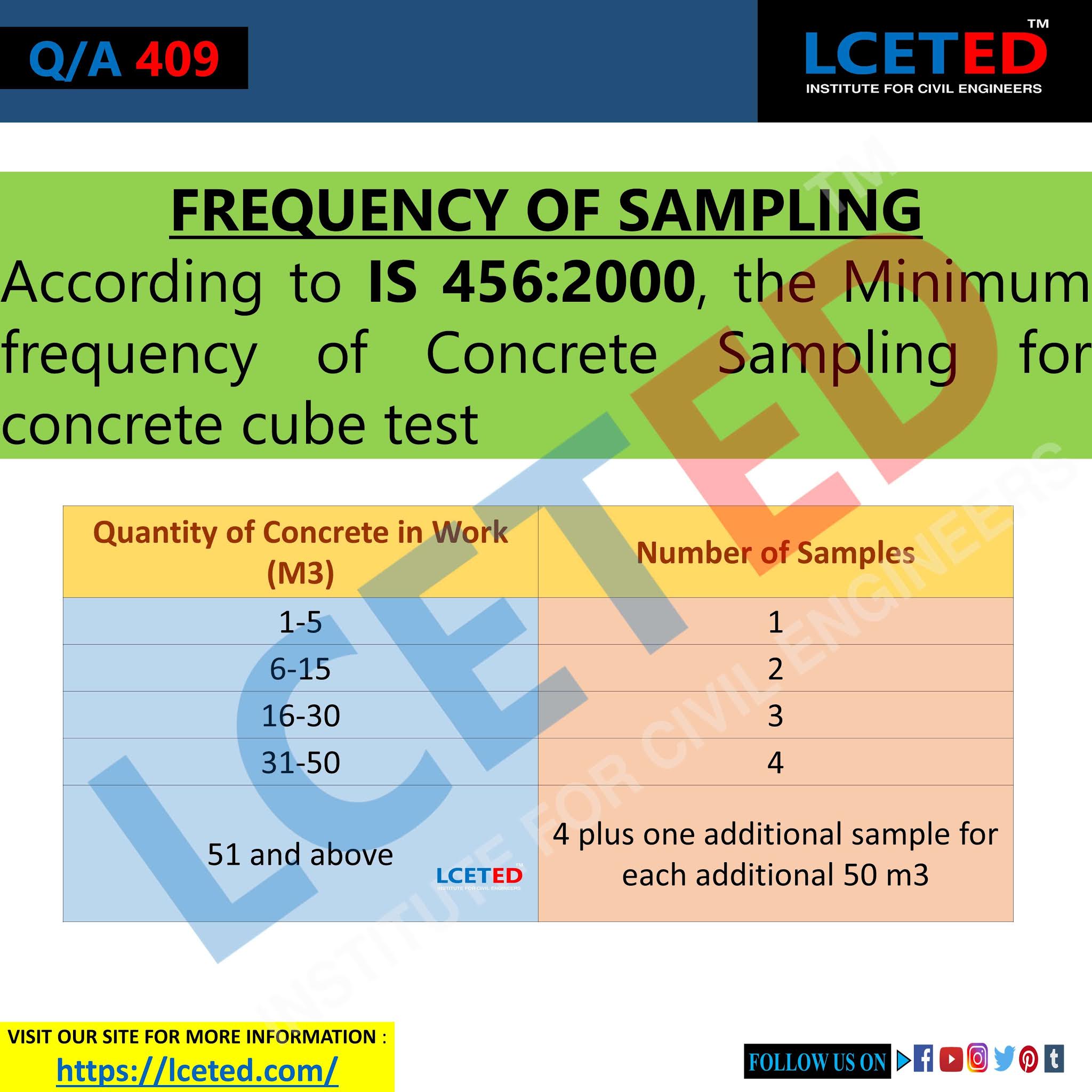

Number

of samples

We should have at least 3 samples

for testing from different batches as mandatory. The mean of compressive

strength achieved by this samples is used to determine the actual strength of the

batch.

Must

read: Laboratory

Tests On Cement | 8 Different Types Of Cement Test | LCETED

PROCEDURE FOR CONCRETE CUBE TEST

1. Remove

the samples from the water after curing time specified and excess water from

the surface should be wiped.

2. The dimension of the samples to the nearest 0.2m taken

3. The bearing surface of the testing machine should be cleaned

4. Place

the sample in the machine so that the load is applied to the opposite sides of

the cube cast.

5. Align

the centre of the sample with the machine's base plate.

6. Rotate

the movable portion gently by hand so that it touches the top surface of the

specimen.

7. Gently

rotate the movable part by hand so that it touches the upper surface of the

sample.

8. Apply

load gradually at a rate of 140 kg / cm2 per minute until the samples fail.

9. The

maximum load recorded and any unusual features in the type of failure noted.

Must read: Curing of Concrete | Reasons | Duration | Types | Weather

CALCULATION

Compressive Strength of

concrete = Maximum compressive load carried by specimen

/ Cross Sectional Area surface of specimen

Take it as,

Cross sectional Area =

150mm X 1500mm = 22500 mm2 or 225 cm2

Assume the compression load

is 400 KN,

Compressive Strength =

(400000 /22500) = 17.77 /9.81 = 181.22 kg/cm2

Note – 1 kg is equal

to 9.81 N

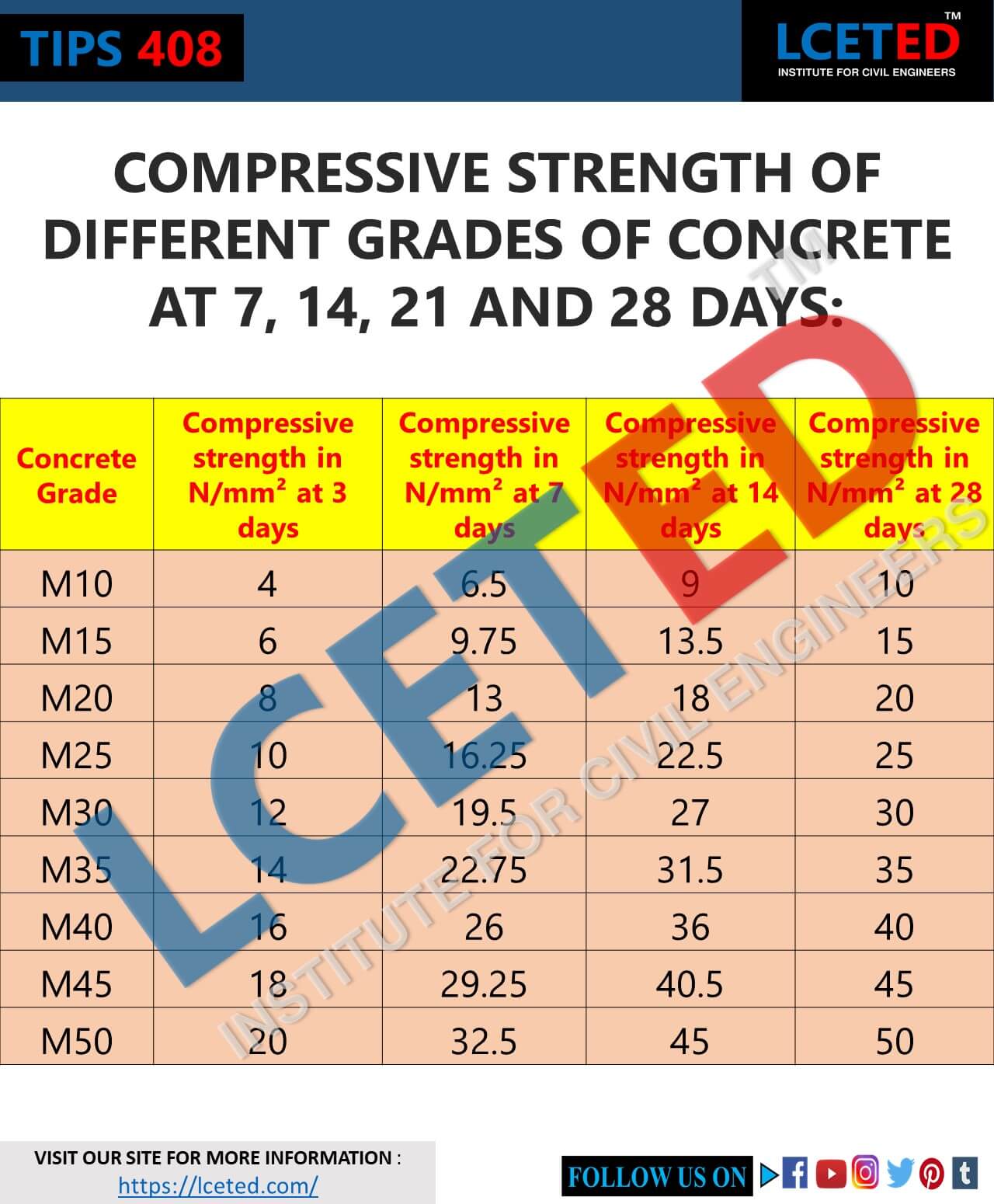

The same calculation is done for the sample at

different ages as stated below:

before that know Q/A 408: Compressive Strength of Concrete at Various Ages

TIPS 408: COMPRESSIVE STRENGTH OF DIFFERENT GRADES OF CONCRETE AT 7, 14, 21 AND 28 DAYS

Note:

At least three samples

should be tested at each selected age as per IS: 516-1959 Which means three samples in 7 days, three samples at

14 days and 28 days If the strength of one sample exceeds 15% of the average

force, such a sample should be rejected.

click to know about Facts On Concrete Strength Test

Must

read: Compaction

factor test | Workability test for concrete | Fresh concrete test

Nut bolt size

ReplyDeleteWhich number speaner

ReplyDelete