TMT steel is available in several variants, which are used by construction and infrastructure companies in residential, commercial and industrial projects. By purchasing the right grade from TMT, procurement managers can benefit from standardization, strength and sustainability within the project.

The

Bureau of Indian Standards classifies TMT steel bars according to their chemical composition and mechanical properties.

Indian

steelmakers follow the referenced standards while providing additional

information on ductility, weldability, corrosion resistance, etc.

Purchasing

managers can look at the Fe grade (rating) reading, as well as the price of the

TMT bar, to understand the effectiveness of the acquired bar.

TMT

bars are classified based on the yield strength they can safely withstand, in

Newtons per square millimeter, without showing permanent deformation. that is,

a Fe500 quality gives a yield strength of 500 N/mm2, beyond which it may not be

able to retain its shape.

TMT rods can also be acquired in different

sizes from

8 mm in diameter to 32 mm.

TYPES OF TMT BARS AND THEIR USE

Procurement managers can map

out core requirements and source the right TMT type with the key properties

necessary for long-term reinforcement. There are 4 main grades that most TMT

bars fall under, namely Fe 415, 500, 550, & 600, making it easier for

buyers when sourcing the right TMT bar.

We can map core requirements and get the

right TMT type with the most important properties that are necessary for

long-term reinforcement. There are four main grade qualities that most TMT bars

(stacks) fall under, namely

Fe 415

Fe 500

Fe 550

Fe 600

which makes it easier for us when buying the

right TMT bars.

DETAILS OF FE 415

GRADE TMT BARS

Fe

415 TMT is a very inexpensive and flexible reinforcement bar made for small

scale construction projects. It bends easily in more complex shapes and it is suitable

for buildings with low load.

CHEMICAL COMPOSITION

& MECHANICAL PROPERTIES OF FE415 GRADE TMT BAR

FE415 USE IN CONSTRUCTION

Fe415

is used to strengthen residential houses, cottages and small-scale structures.

They have a more uniform length and can be used to create projects in areas

affected by the earthquake.

Construction

companies can choose Fe415S or Fe415D if additional seismic stability or flexible

is required.

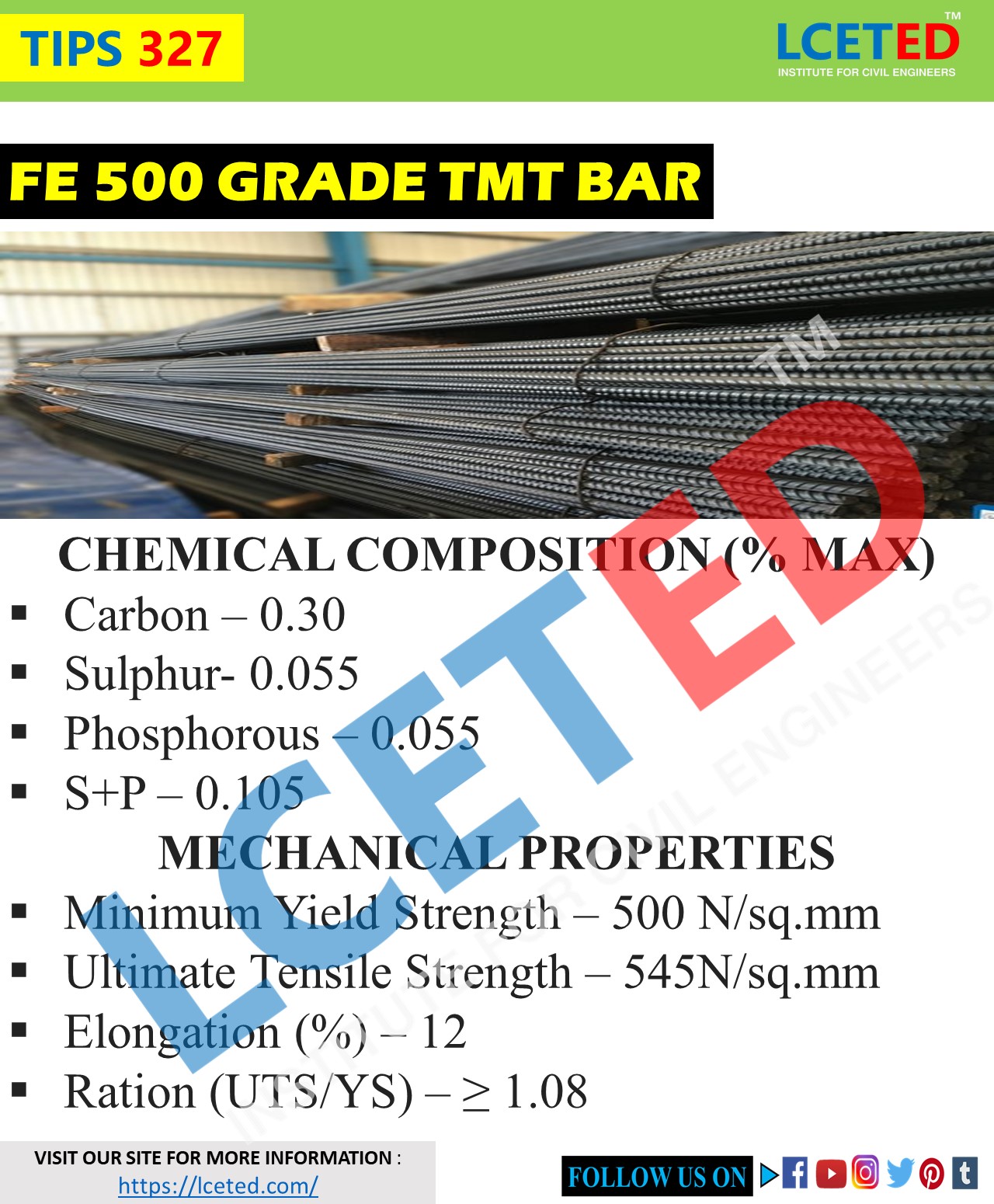

DETAILS OF FE 500

GRADE TMT BARS

Fe500 quality is generally

considered the market quality used in many construction projects. Its

alternatives, the Fe 500D and Fe 500S are popular choices that offer high

seismic stability and ductility.

CHEMICAL COMPOSITION

& MECHANICAL PROPERTIES OF FE500 GRADE TMT BAR

FE500 USE IN CONSTRUCTION

Fe

500 bars can be used in residential, commercial and multi-story projects. They

offer higher tensile strength than Fe 415 and are specially designed to

ensure the stability of large projects while resisting loads better.

In

addition, Fe 500D bars offer high durability, making them ideal for

construction in areas with high seismic activity and sudden loads.

DETAILS OF FE 550

GRADE TMT BARS

Fe

550-grade bars have high tensile strength and can be used in large budget projects.

CHEMICAL COMPOSITION

& MECHANICAL PROPERTIES OF FE550 GRADE TMT BAR

FE550 USE IN CONSTRUCTION

We

can select Fe 550 quality TMT bars when creating industrial and large design

infrastructure projects. Bridges, industrial projects and structures require

high load capacity may benefit from the Fe 550 standard TMT. They also have an

impact on coastal, marine and underground environments in particular.

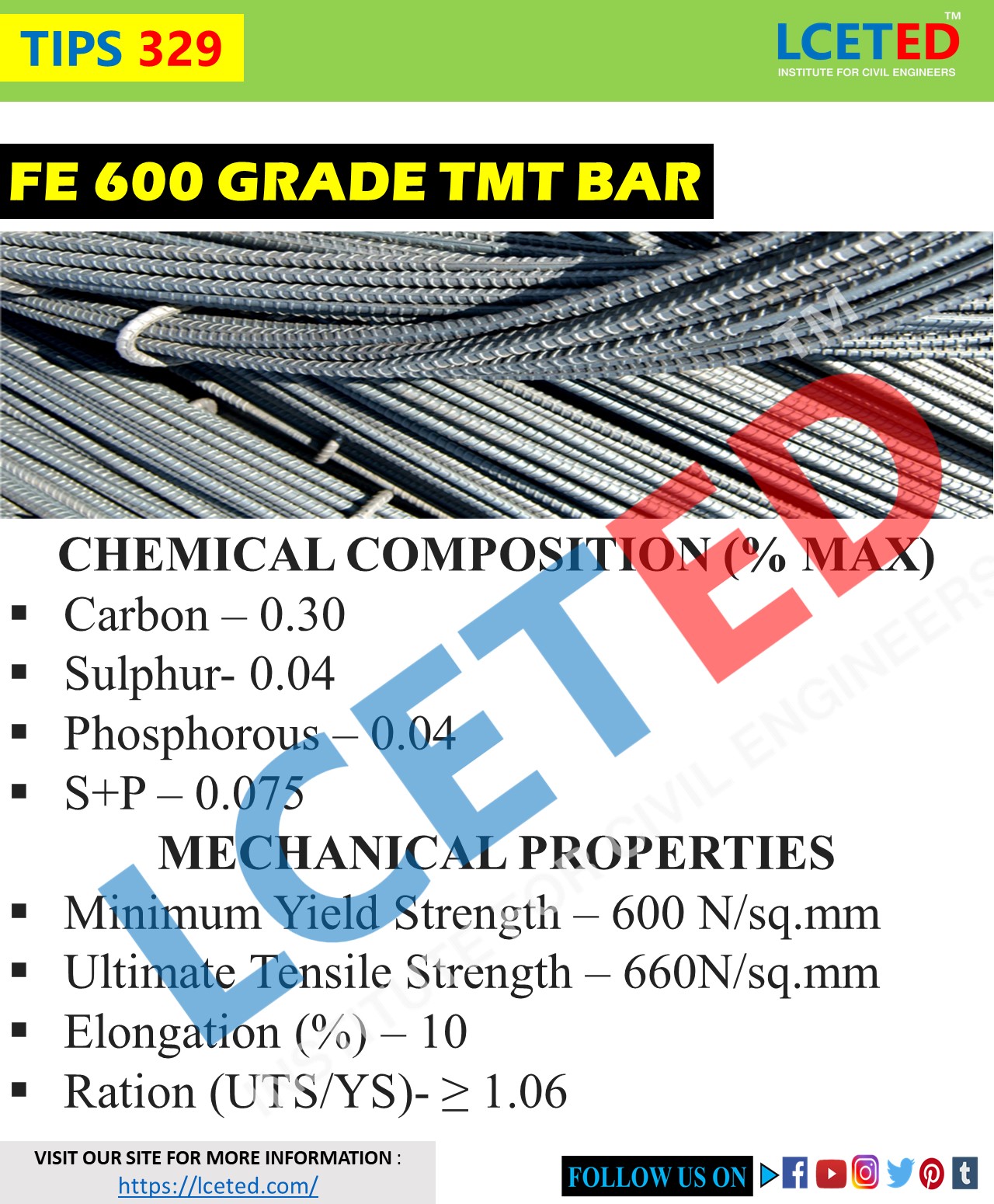

DETAILS OF FE 600 GRADE TMT BARS

Fe

600 is one of the strongest standards of TMT that construction companies can

obtain when building heavy infrastructure projects, bridges, marine

installations, etc.

They

offer greater tensile strength, reduce overall consumption and ensure less

congestion of the steel in the reinforcement.

CHEMICAL COMPOSITION

& MECHANICAL PROPERTIES OF FE600 GRADE TMT BAR

FE600 USE IN

CONSTRUCTION

Fe 600 TMT bars used in the construction of

metro projects, towers, plants, expressways commercial properties, and

industrial zones. They used widely when large-scale projects need to be built with load-bearing, durability, and corrosion-resistance capacity.

CONCLUSION

Proper

TMT grade bars should be used based on key project requirements, quality

standards and project specifications. We should purchase TMT bars driven by

high-quality feature manufactured by leading steel manufacturing companies.

I'd like to publish a translation of this article on my blog ( https://ahanspot.com ). Is it okay?

ReplyDeleteThis article is worth sharing, with all-inclusive information on the different grades of TMT bars. Read out blog https://megaturbotmt.com/tmt-bar-types-uses-advantages/

ReplyDelete